2025 Top Round Carbide Rods for Precision and Durability

In the ever-evolving landscape of manufacturing and precision engineering, the significance of high-quality materials cannot be overstated. Round Carbide Rods, known for their exceptional hardness and durability, have become indispensable in various applications, from cutting tools to industrial machinery. According to Dr. Emily Thompson, a leading expert in material science, “The reliability of Round Carbide Rods can dramatically influence the efficiency and precision of production processes.”

As industry demands grow for better performance and longevity, understanding the properties and best uses of Round Carbide Rods becomes crucial. In this guide, we will explore the top Round Carbide Rods available by 2025, highlighting their unique characteristics and applications. By delving into innovations and advancements in carbide rod technology, we aim to assist engineers and manufacturers in making informed choices that can enhance their production capabilities and reduce downtime.

Join us as we unravel the essential features that define the best Round Carbide Rods on the market and discuss expert recommendations to ensure your operations remain at the forefront of precision and durability. With the right knowledge and resources, navigating the array of options will empower you to choose rods that not only meet but exceed your manufacturing needs.

Overview of Round Carbide Rods: Composition and Properties for Precision Tools

Round carbide rods are essential components in the manufacturing of precision tools, known for their exceptional hardness and durability. Composed primarily of tungsten carbide, these rods offer superior wear resistance and maintain their structural integrity under high temperatures. According to a report by MarketsandMarkets, the global carbide market is projected to reach USD 17.51 billion by 2025, driven by the increasing demand for high-performance tools in various industries, including automotive, aerospace, and electronics.

The properties of round carbide rods, such as their high density (approximately 14.5 g/cm³) and brittle nature, make them ideal for cutting, drilling, and milling applications. Their hardness, rated between 70 and 81 HRC (Rockwell hardness scale), allows for precision machining with minimal tool wear. Additionally, studies suggest that the fine grain size of the carbide enhances its mechanical properties, enabling the production of tools that can withstand rigorous operational demands. This combination of composition and properties solidifies round carbide rods as a top choice for precision tooling applications.

Key Benefits of Using Carbide Rods in Industrial Applications

Carbide rods have become an essential material in various industrial applications due to their exceptional properties, making them a preferred choice for precision tooling and manufacturing. According to a recent report by Markets and Markets, the global carbide tools market is projected to reach USD 21 billion by 2025, highlighting the indispensable role of carbide rods in enhancing operational efficiency. The superior hardness and wear resistance of carbide rods significantly reduce tool wear, thereby extending the lifespan of industrial equipment and minimizing downtime.

One of the key benefits of using carbide rods is their ability to withstand extreme conditions, such as high temperatures and abrasive environments. A study from Grand View Research indicates that carbide tools can last up to 20 times longer than their high-speed steel counterparts, reducing replacement costs and enhancing productivity. Furthermore, the precision machining capabilities of carbide rods lead to tighter tolerances and improved surface finishes, which are vital in sectors like aerospace and automotive manufacturing where accuracy is paramount. This combination of durability and precision makes carbide rods an invaluable asset for industries striving to optimize their processes.

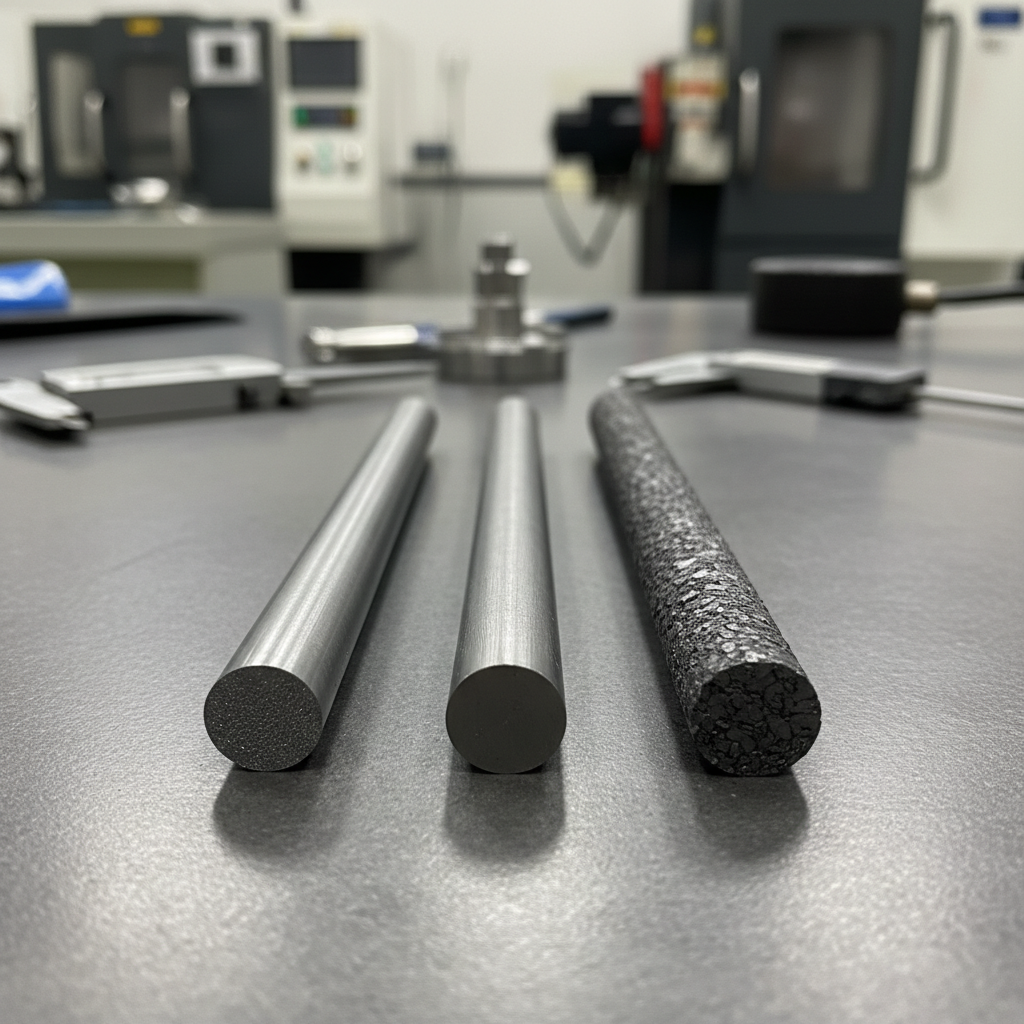

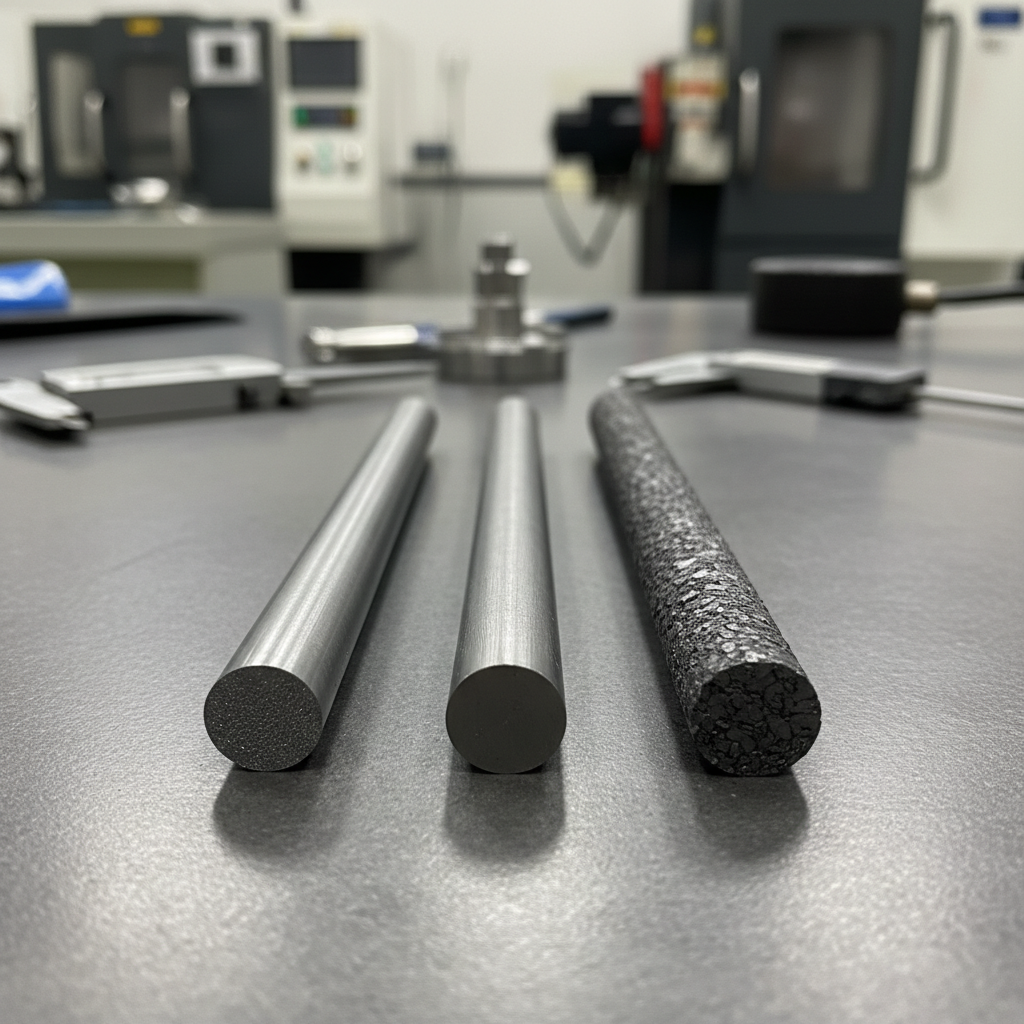

Comparison of Different Types of Carbide Rods: Grade Selection and Performance

When selecting carbide rods for precision machining, understanding the differences between various grades is crucial for optimal performance. Carbide rods are primarily composed of tungsten carbide, with additives such as cobalt influencing their hardness and toughness.

The most common grades are fine, medium, and coarse.

Fine grades are typically used for high-speed cutting applications due to their superior edge retention and wear resistance, making them ideal for intricate designs. Medium grades offer a balance of toughness and wear resistance, suited for general-purpose machining, while coarse grades excel in heavy-duty applications requiring high impact resistance.

Performance also varies based on the type of carbide used. For instance, rods with a higher cobalt content demonstrate enhanced ductility, allowing them to withstand more significant stresses without fracturing. Conversely, rods with lower cobalt ratios tend to be harder and more brittle, making them less suitable for applications that involve shock loading.

Therefore, selecting the right grade and type of carbide rod not only influences the efficiency and quality of machining operations but also impacts tool longevity and production costs, making informed decisions essential for any precision engineering project.

Industry Standards and Testing for Precision and Durability of Carbide Products

The precision and durability of carbide rods are pivotal in various industrial applications, especially in machining and manufacturing sectors where tolerance levels are rigorous. According to the "Carbide Tooling Market Research Report 2023," the global demand for high-performance carbide products has increased by approximately 15% year-over-year, reflecting the need for materials that can withstand extreme conditions while maintaining accuracy. Testing standards such as ASTM B 851-06 evaluate the hardness and wear resistance of carbide products, ensuring they meet stringent industry requirements.

In addition to industry standards, advanced testing methodologies like the Rockwell hardness test and the wear assessment using the ASTM G 99 provide insights into the lifespans and reliability of carbide rods. A study published in the "Journal of Materials Science" indicated that carbide rods exhibiting optimal hardness levels (average hardness above HRA 90) demonstrated a 30% longer operational lifespan compared to lower-grade alternatives. As industries continue to prioritize precision in production processes, adherence to these established standards will be crucial for manufacturers aiming to deliver durable, high-quality carbide rods in 2025 and beyond.

2025 Top Round Carbide Rods for Precision and Durability

This chart displays the comparison of precision and durability testing results for different grades of round carbide rods in 2025. Each grade demonstrates varying levels of performance in both precision and durability, which are crucial for industrial applications.

Market Trends: Innovation and Demand for High-Quality Carbide Rods by 2025

The demand for high-quality carbide rods is expected to surge significantly by 2025, driven by innovation in machining and manufacturing processes. According to a recent report by MarketsandMarkets, the global carbide tools market is projected to reach USD 18.21 billion by 2025, with a compound annual growth rate (CAGR) of 7.6% from 2020 to 2025. This growth reflects an increasing need for precision tooling in industries such as aerospace, automotive, and electronics, where the performance and durability of tools play a crucial role.

Innovative advancements in carbide rod technology are a key factor propelling this market trend. Enhanced coatings and new alloy compositions are being developed to improve wear resistance and thermal stability, as highlighted in a report from Technavio, which notes that the focus on manufacturing efficiency is pushing suppliers to integrate advanced materials in their products. As industries look to optimize production and reduce downtime, the incorporation of high-quality carbide rods is becoming essential, ensuring precision in even the most demanding applications.

2025 Top Round Carbide Rods for Precision and Durability - Market Trends: Innovation and Demand for High-Quality Carbide Rods by 2025

| Diameter (mm) |

Length (mm) |

Grade |

Hardness (HRA) |

Market Share (%) |

Projected Growth Rate (%) |

| 6 |

100 |

K10 |

90 |

15 |

5 |

| 8 |

150 |

K20 |

92 |

18 |

6 |

| 10 |

200 |

K30 |

93 |

20 |

7 |

| 12 |

250 |

K40 |

95 |

22 |

8 |

| 15 |

300 |

K50 |

96 |

25 |

9 |

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us