Understanding the Advantages of Using Blank Carbide Plates in Modern Manufacturing

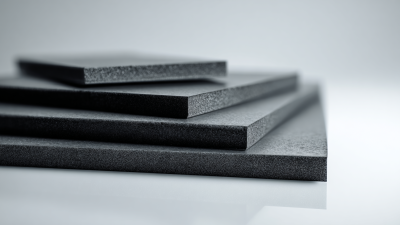

In modern manufacturing, the choice of materials can significantly influence the efficiency and quality of production processes. One such material that has gained prominence is the Blank Carbide Plate. These plates are renowned for their exceptional hardness, wear resistance, and ability to withstand high temperatures, making them ideal for a wide range of industrial applications. The advantages of utilizing Blank Carbide Plates extend beyond their physical properties; they also contribute to improved machining precision, reduced tool wear, and increased productivity. As manufacturers continuously seek ways to enhance their operational effectiveness and product quality, understanding the benefits of these versatile plates becomes essential. In this article, we will delve into the various reasons why incorporating Blank Carbide Plates into manufacturing processes can lead to significant advancements in both performance and cost-efficiency.

Advantages of Blank Carbide Plates in Precision Manufacturing

Blank carbide plates have become increasingly popular in precision manufacturing due to their remarkable properties that enhance efficiency and durability.

Composed of tungsten carbide, these plates exhibit exceptional hardness, which makes them an ideal choice for tools and machinery that require high precision and wear resistance.

According to a report by Grand View Research, the global market for tungsten carbide is expected to reach USD 37.99 billion by 2025, highlighting the growing reliance on carbide materials in various manufacturing processes.

One of the key advantages of blank carbide plates is their ability to maintain dimensional stability under extreme conditions. This stability enables manufacturers to achieve tighter tolerances in their products, reducing the need for rework and wastage.

A technical report by the Manufacturing Institute indicates that companies utilizing carbide tooling experience up to a 25% reduction in production costs due to lowered tool wear and increased operational efficiency.

Furthermore, blank carbide plates are highly versatile and can be customized for various applications, making them a valuable asset in the precision engineering sector.

Applications of Blank Carbide Plates in Various Industries

Blank carbide plates are increasingly being utilized across various industries, thanks to their unique properties that enhance manufacturing processes. These plates provide exceptional hardness and wear resistance, making them ideal for applications in demanding environments such as aerospace, automotive, and construction. In the aerospace sector, for instance, blank carbide plates serve as essential components in cutting tools and wear parts, where durability is crucial. Similarly, in the automotive industry, they are used in manufacturing precision parts that require high strength and resilience.

The growth of the aluminum silicon carbide market further emphasizes the importance of advanced materials like blank carbide plates. As industries strive for lighter and stronger materials to improve efficiency and performance, the integration of carbide plates becomes increasingly relevant. Their applications extend to the electronics sector as well, where they support the production of thermal management components, enhancing the reliability and functionality of electronic devices. As the manufacturing landscape evolves, the demand for such durable materials is expected to rise, providing significant opportunities for innovation across multiple sectors.

Comparative Analysis: Carbide Plates vs. Traditional Materials

In the realm of modern manufacturing, the shift towards blank carbide plates signifies a transformative approach compared to traditional materials like steel or aluminum. Carbide plates offer superior hardness and wear resistance, making them ideal for high-performance applications. This is particularly advantageous in processes such as machining and cutting, where tool longevity directly impacts productivity and cost-effectiveness. The ability to withstand high temperatures without deformation further enhances carbide plates over their traditional counterparts.

**Tip:** To maximize the benefits of carbide plates, ensure proper tooling and maintenance processes are in place. Regular assessments of wear patterns can lead to timely replacements and better operational efficiency.

Moreover, carbide plates are often lighter than traditional materials, reducing the overall weight of manufacturing equipment. This facilitates easier handling and transportation, ultimately contributing to operational efficiency. Their ability to maintain structural integrity under extreme conditions means that manufacturers can rely on carbides for consistent performance, thereby minimizing downtime.

**Tip:** When selecting materials for manufacturing processes, evaluate the specific demands of your applications. Investing in higher-performance materials like carbide plates may lead to significant long-term savings and enhanced product quality.

The Role of Blank Carbide Plates in Reducing Manufacturing Costs

The integration of blank carbide plates in modern manufacturing processes plays a significant role in reducing manufacturing costs. These plates, known for their durability and wear resistance, enhance the longevity of tools and machinery, leading to decreased downtime and maintenance expenses. As industries increasingly shift towards high-performance materials, including carbide, they find that these plates can withstand extreme conditions, ensuring consistent production quality while minimizing the need for frequent replacements.

Moreover, the use of blank carbide plates aligns with the growing trend of adopting advanced materials in semiconductor manufacturing. Companies are now investing in materials that not only improve production efficiency but also lower operational costs. By utilizing carbide technology, manufacturers can achieve better cutting speeds and precision in machining, ultimately translating to cost savings across the production line. This approach is particularly relevant in the context of evolving market demands, such as those driven by the advancements in electric vehicles and renewable energy technologies, where efficiency and cost-effectiveness are paramount.

Future Trends in the Use of Blank Carbide Plates in Production

The future of manufacturing is undoubtedly intertwined with the increased utilization of blank carbide plates. As industries seek to enhance productivity and durability, these plates are gaining traction due to their superior hardness and resistance to wear. This robust material is particularly invaluable in sectors such as aerospace and automotive, where precision and reliability are paramount. Advances in technology are enabling manufacturers to develop even more sophisticated carbide compositions, which can lead to improved performance in high-stress applications.

In the coming years, we are likely to witness a shift in production techniques that incorporate smart manufacturing principles. The integration of IoT and data analytics in the creation of blank carbide plates will not only optimize the production processes but also allow for better customization to meet specific client needs. As the demand for sustainable manufacturing grows, the efficient recyclability of carbide materials could pave the way for a circular economy model within the industry, further consolidating the role of blank carbide plates in modern and future manufacturing practices.

Understanding the Advantages of Using Blank Carbide Plates in Modern Manufacturing

Chart representing the advantages of using blank carbide plates in modern manufacturing processes. Each category is rated on a scale of 0 to 100, depicting their relative significance.

Home

About Us

Products

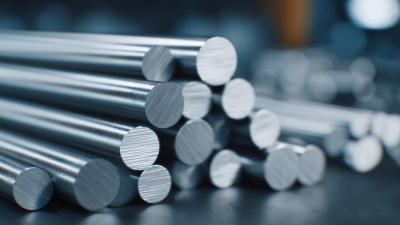

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

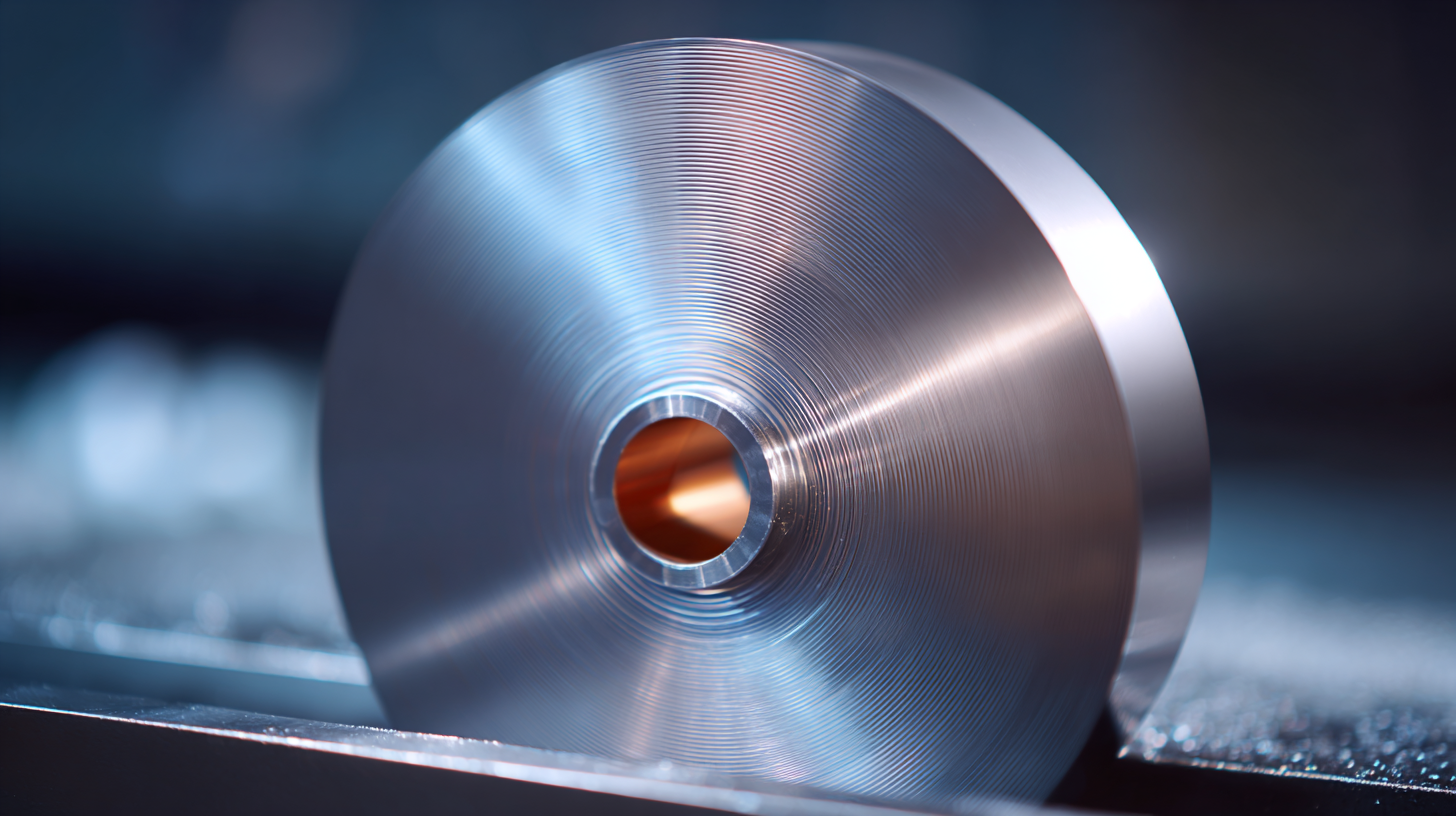

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us