Exploring the Benefits and Applications of Carbide Round Bars in Modern Manufacturing

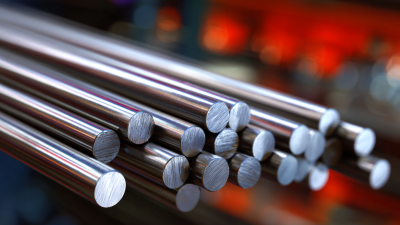

In the realm of modern manufacturing, the significance of high-performance materials cannot be overstated, with

Carbide Round Bars standing out as a leading choice due to their exceptional hardness and wear resistance.

According to a report by the Global Carbide Tools Market, the demand for carbide products is projected to grow at a

CAGR of 5.2% over the next five years, driven by advancements in machining technologies and increasing production capacities across various industries.

Carbide Round Bars are not only essential in the production of precision tools but also play a crucial role in sectors such as

aerospace, automotive, and energy, where

durability and efficiency are paramount. This exploration will delve into the benefits and diverse applications of Carbide Round Bars,

illuminating their integral role in enhancing productivity and sustaining competitive advantages in today's manufacturing landscape.

Benefits of Carbide Round Bars in Precision Manufacturing Applications

Carbide round bars play a crucial role in precision manufacturing applications, offering exceptional performance and durability. Made from tungsten carbide, these bars are known for their high hardness, wear resistance, and ability to withstand extreme temperatures. According to a report by MarketsandMarkets, the global tungsten carbide market is projected to reach USD 28.23 billion by 2026, highlighting the growing demand for carbide materials in manufacturing sectors. This trend is driven by the need for precision components that can maintain accuracy and integrity under various operational conditions.

In precision manufacturing, carbide round bars are commonly used for machining tools, cutting tools, and wear parts due to their superior characteristics. For instance, a study from Research and Markets indicates that the tools segment is expected to hold the largest market share, primarily because carbide tools offer extended tool life and consistent performance. This translates to reduced downtime and lower production costs, making carbide round bars an attractive option for manufacturers striving for efficiency and quality in their production processes. By leveraging the benefits of carbide round bars, businesses can enhance their competitive edge in an increasingly demanding market.

Exploring the Benefits and Applications of Carbide Round Bars in Modern Manufacturing

| Application Area |

Benefits |

Material Composition |

Common Uses |

| Aerospace Manufacturing |

High wear resistance and durability |

Tungsten Carbide, Cobalt |

Engine components, landing gear parts |

| Medical Devices |

Biocompatibility and precision |

Titanium Carbide, Nickel |

Surgical instruments, implants |

| Automotive Industry |

Enhanced strength and reduced friction |

Ceramic Coated Carbide |

Gear shafts, valves, cutting tools |

| Electronics Manufacturing |

Precision machining and longer tool life |

Tungsten Carbide, Titanium |

Microprocessors, circuit boards |

| Oil and Gas Industry |

Corrosion resistance and high strength |

Tungsten Carbide, Cobalt |

Drilling tools, valves, pumps |

Applications of Carbide Round Bars in Diverse Industrial Sectors

Carbide round bars have found extensive applications across various industrial sectors, primarily due to their remarkable properties such as high hardness, wear resistance, and durability. In manufacturing, these bars are instrumental in producing cutting tools, dies, and molds, which require materials capable of enduring extreme conditions during machining processes. The aerospace and automotive industries particularly benefit from carbide round bars, as they ensure precision and longevity in components that operate under high-stress environments.

Carbide round bars have found extensive applications across various industrial sectors, primarily due to their remarkable properties such as high hardness, wear resistance, and durability. In manufacturing, these bars are instrumental in producing cutting tools, dies, and molds, which require materials capable of enduring extreme conditions during machining processes. The aerospace and automotive industries particularly benefit from carbide round bars, as they ensure precision and longevity in components that operate under high-stress environments.

Additionally, carbide round bars are increasingly utilized in the energy sector, where their ability to withstand high temperatures and corrosive substances is crucial. For instance, in nuclear energy applications, these materials can effectively contribute to the manufacturing of components that enhance the efficiency and safety of reactors. As industries continue to innovate and seek environmentally friendly solutions, the relevance of carbide round bars is expected to grow, further diversifying their applications in modern manufacturing.

Comparative Analysis: Carbide Round Bars vs. Traditional Materials

Carbide round bars present numerous advantages over traditional materials in the manufacturing sector, primarily due to their superior hardness and wear resistance. While traditional materials like high-speed steel typically serve efficiently for general purposes, carbide significantly outperforms them in longevity and precision. This is particularly evident in high-demand applications where consistent performance is crucial. The hardness of carbide allows for sharper cutting edges and greater tool lifespan, which translates into reduced downtime and lower tool replacement costs for manufacturers.

A comparative analysis reveals that the choice between carbide round bars and traditional materials largely depends on the specific manufacturing needs. For instance, in drilling and milling operations, carbide tools enable faster machining rates and can maintain performance under higher temperatures. In contrast, while traditional materials may suffice for low-volume or less critical operations, they lack the extended durability required for more demanding tasks. Consequently, the trend in modern manufacturing is increasingly leaning towards carbide tools, as industries recognize the long-term cost savings and efficiency gains that they offer.

Comparative Analysis of Carbide Round Bars vs. Traditional Materials

Innovative Manufacturing Techniques Using Carbide Round Bars

The innovative applications of carbide round bars in modern manufacturing have revolutionized various sectors, particularly in machining and fabrication processes. These round bars, made from tungsten carbide, are renowned for their exceptional hardness and wear resistance, making them ideal for demanding environments. In machining, carbide round bars are often utilized in the production of cutting tools such as drills, end mills, and inserts, where they significantly enhance tool longevity and performance. Their ability to withstand high temperatures and pressures allows for precision machining at higher speeds, improving overall productivity and efficiency.

Furthermore, carbide round bars are increasingly being integrated into advanced manufacturing techniques, such as additive manufacturing and CNC machining. In additive manufacturing, they serve as robust materials that contribute to the development of intricate components with high durability. CNC machining, on the other hand, benefits from carbide round bars' precision attributes, allowing manufacturers to achieve tighter tolerances and superior surface finishes. This adaptability not only streamlines production processes but also opens up new possibilities for innovation, enabling manufacturers to create complex geometries that meet the evolving demands of industries such as aerospace, automotive, and medical device manufacturing.

Cost Efficiency and Longevity of Carbide Round Bars in Production

Carbide round bars have emerged as a pivotal component in modern manufacturing due to their remarkable cost efficiency and longevity. These robust materials, known for their superior hardness and resistance to wear, significantly reduce operational costs over time. Unlike traditional materials, carbide round bars can withstand high levels of stress and corrosion, leading to fewer replacements and less downtime in production processes. This durability not only enhances productivity but also lowers maintenance expenses, making them an attractive option for industries looking to optimize their manufacturing lines.

Additionally, the longevity of carbide round bars contributes to the sustainability efforts within manufacturing. By minimizing the need for constant replacements, manufacturers can lower their material waste and reduce their environmental footprint. This quality aligns with the industry's shift towards more responsible practices. Furthermore, the efficiency achieved with carbide round bars translates into better resource management, positioning companies to remain competitive while embracing eco-friendly initiatives. As such, the adoption of carbide round bars serves not only as a strategic economic decision but also as a commitment to sustainable manufacturing.

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us

Carbide round bars have found extensive applications across various industrial sectors, primarily due to their remarkable properties such as high hardness, wear resistance, and durability. In manufacturing, these bars are instrumental in producing cutting tools, dies, and molds, which require materials capable of enduring extreme conditions during machining processes. The aerospace and automotive industries particularly benefit from carbide round bars, as they ensure precision and longevity in components that operate under high-stress environments.

Carbide round bars have found extensive applications across various industrial sectors, primarily due to their remarkable properties such as high hardness, wear resistance, and durability. In manufacturing, these bars are instrumental in producing cutting tools, dies, and molds, which require materials capable of enduring extreme conditions during machining processes. The aerospace and automotive industries particularly benefit from carbide round bars, as they ensure precision and longevity in components that operate under high-stress environments.