Exploring the Benefits of Using Polished Tungsten Plates in Modern Manufacturing

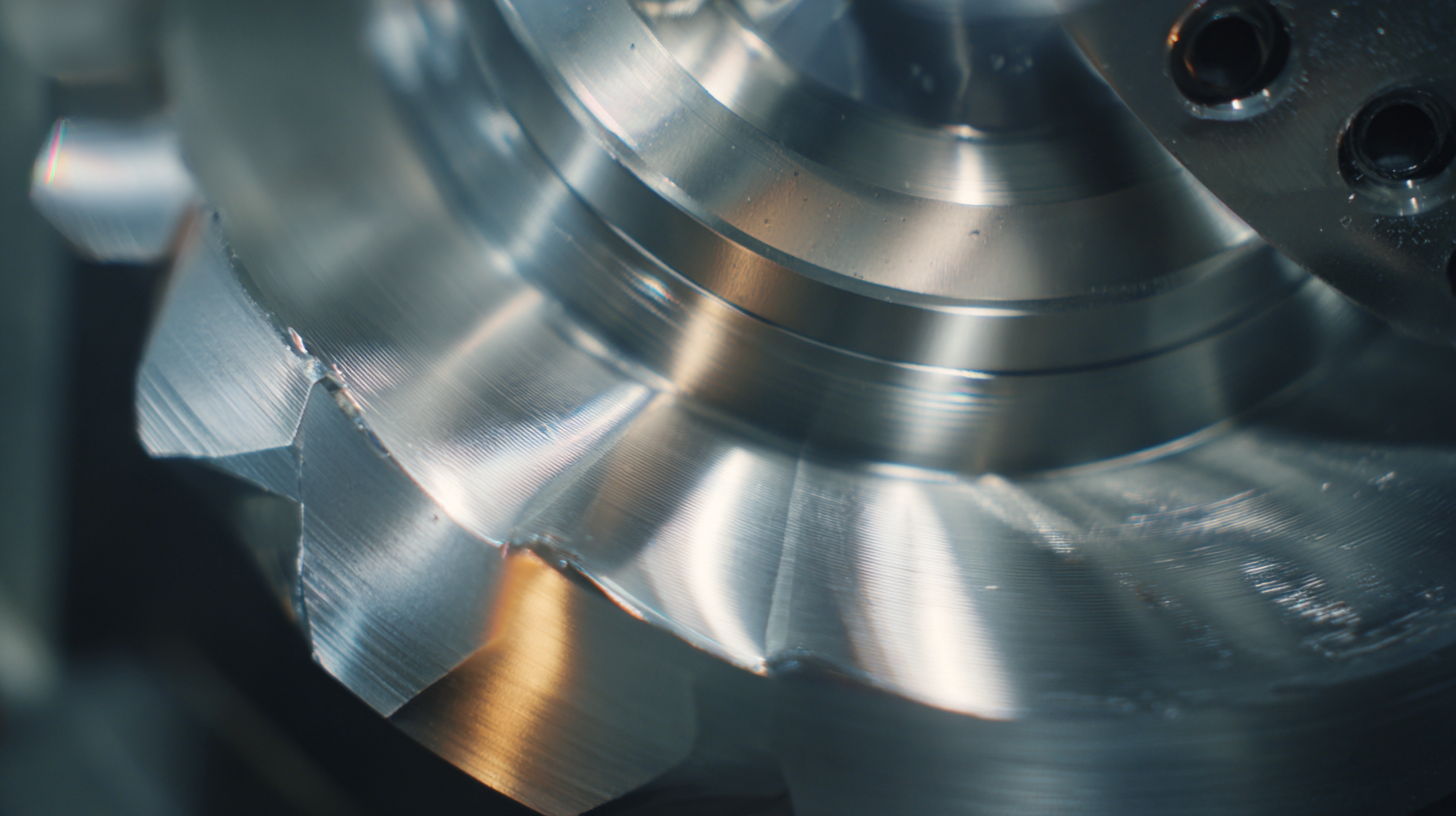

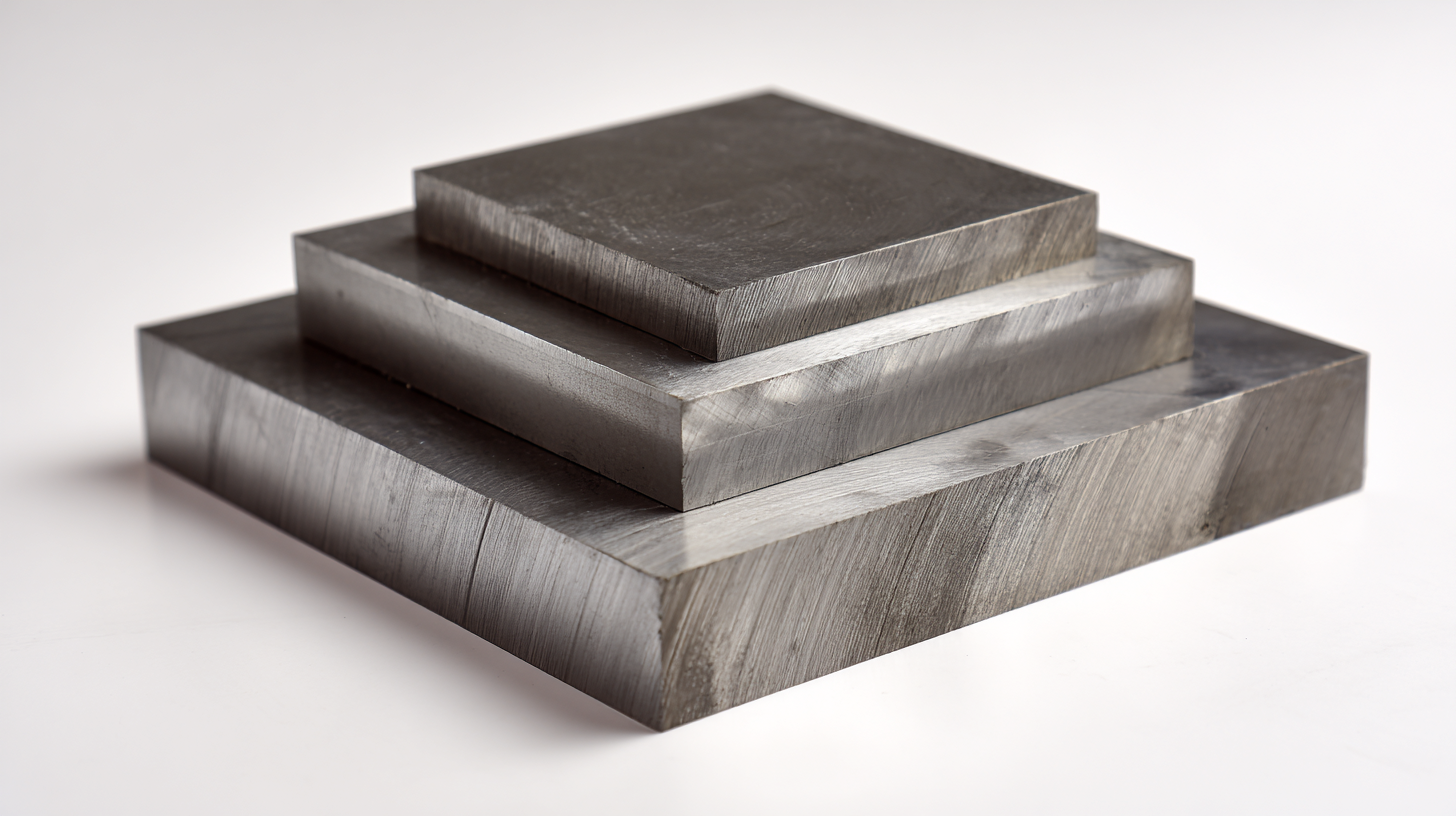

In the realm of modern manufacturing, the quest for materials that combine durability, versatility, and precision has never been more critical. Among the various options available, the Polished Tungsten Plate has emerged as a leading candidate due to its unique properties and wide-ranging applications. Tungsten, renowned for its exceptional hardness and high melting point, when polished, enhances its aesthetic appeal and functional performance, making it suitable for various industrial processes.

The adoption of

Polished Tungsten Plates in manufacturing not only improves the quality of the final products but also contributes to more efficient production methods. Its ability to withstand extreme operational conditions while providing a

smooth surface finish is unparalleled, leading to reduced wear and tear on equipment, enhanced lifespan, and lower maintenance costs. As industries evolve and require more innovative solutions, understanding the benefits of Polished Tungsten Plates becomes essential for manufacturers aiming to stay ahead in a competitive landscape.

In essence, exploring the advantages of Polished Tungsten Plates is key to unlocking improved performance and productivity in manufacturing processes. Whether for aerospace, electronics, or specialized tooling, the integration of this remarkable material can provide a significant

competitive edge in a rapidly changing market. As we delve deeper into the benefits and applications of Polished Tungsten Plates, it becomes clear that they are not just a choice but a strategic investment for modern manufacturing.

Advantages of Polished Tungsten Plates in Precision Manufacturing

Polished tungsten plates are becoming increasingly popular in the realm of precision manufacturing due to their unique characteristics. One of the primary advantages of these plates is their exceptional hardness and durability. Tungsten, being one of the hardest metals, can withstand significant wear and tear, making it ideal for applications that require resilience under extreme conditions. This strength translates to longer-lasting tools and components, reducing the frequency of replacements and maintenance costs for manufacturers.

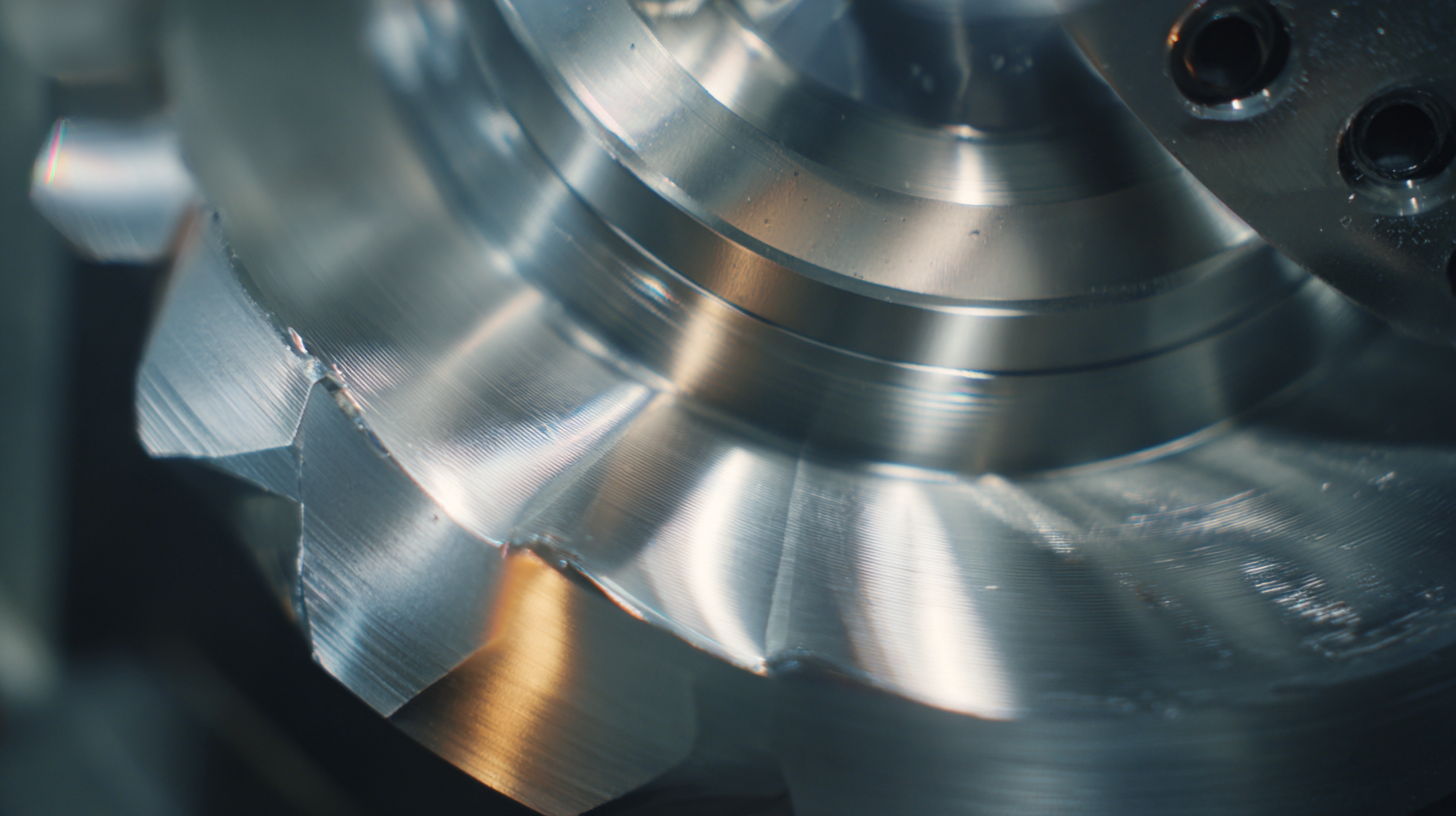

In addition to their mechanical properties, polished tungsten plates offer significant benefits in terms of thermal conductivity and stability. Their ability to dissipate heat efficiently allows for improved performance in processes involving high temperatures, such as welding and machining. Furthermore, the smooth surface finish of polished tungsten minimizes friction during operation, which not only enhances precision but also contributes to a better quality of the final product. This combination of durability, thermal efficiency, and precision makes polished tungsten plates a valuable asset in modern manufacturing techniques.

Benefits of Using Polished Tungsten Plates in Modern Manufacturing

Impact of Polished Tungsten Plates on Product Quality and Durability

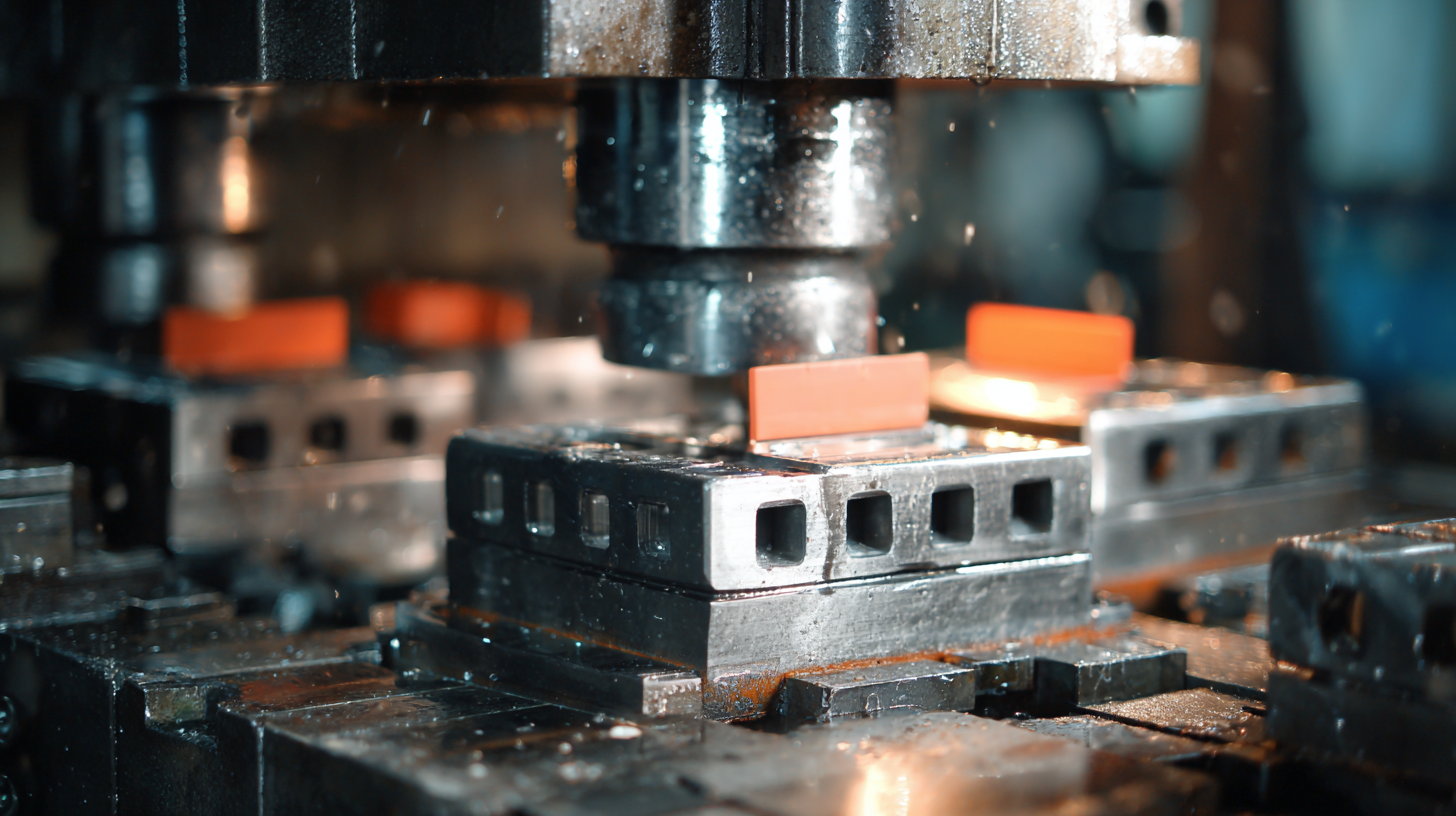

Polished tungsten plates have increasingly become a vital component in modern manufacturing, particularly in industries that demand high precision and reliability. One of the key advantages of using these plates is their superior surface finish, which contributes significantly to product quality. According to a recent industry report by the International Journal of Advanced Manufacturing Technology, products that incorporate polished tungsten components exhibit a 25% increase in wear resistance, leading to extended service life and reduced maintenance costs. This enhanced durability is particularly beneficial in sectors such as aerospace and electronics, where material performance is critical.

Moreover, the high density and exceptional thermal conductivity of polished tungsten plates play a crucial role in improving the overall functionality of manufactured products. A study from the Materials Science and Engineering journal highlights that the uniform heat distribution enabled by tungsten plates can enhance the performance of thermal management systems in electronic devices by up to 30%. This not only ensures better reliability but also contributes to the energy efficiency of the final products, making polished tungsten an attractive option for manufacturers looking to improve both quality and durability in their offerings.

Cost-Effectiveness of Using Polished Tungsten Plates in Production

Polished tungsten plates are increasingly recognized for their cost-effectiveness in modern manufacturing processes. Their durability and resistance to wear make them an ideal choice for various applications, reducing the need for frequent replacements and repairs. This not only lowers material costs but also minimizes production downtime, translating to significant savings over time. Furthermore, tungsten's unique properties, such as high density and excellent thermal conductivity, contribute to enhanced efficiency in manufacturing operations.

In addition to their economic benefits, polished tungsten plates can improve product quality. The smooth surface finish allows for better precision in machining and assembly, leading to higher-quality outputs and reduced scrap rates. As manufacturers strive for leaner production practices, the use of polished tungsten plates can support these initiatives by streamlining processes and improving overall productivity. Despite concerns related to health issues in some contexts, the strategic use of tungsten in manufacturing aligns well with the industry’s goal of balance between performance and cost-effectiveness.

Applications of Polished Tungsten Plates Across Various Industries

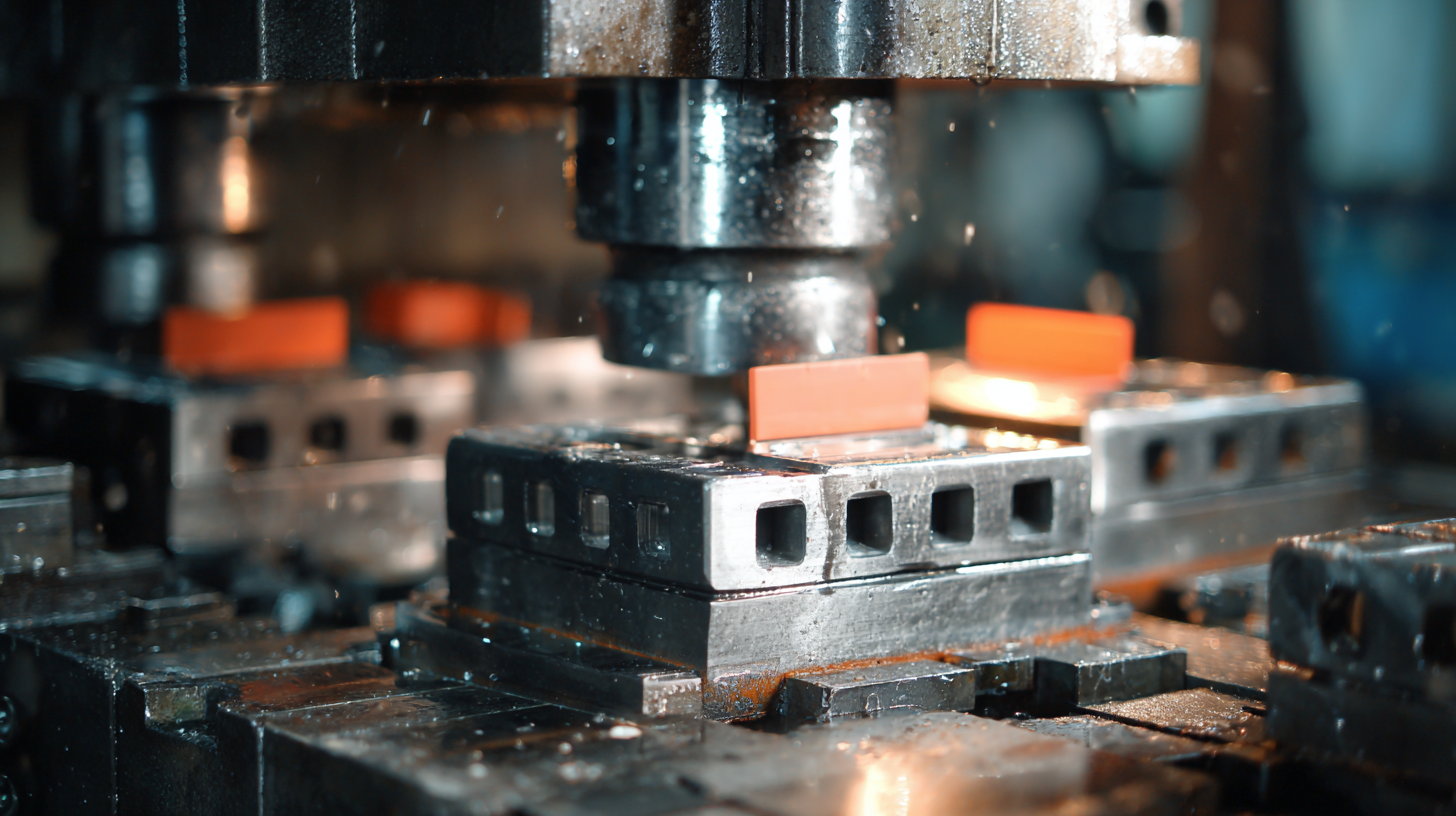

Polished tungsten plates are gaining attention across various industries due to their exceptional properties, including high density, superior hardness, and excellent resistance to corrosion and wear. In hydraulic axial piston pumps, for instance, there is a growing shift from traditional leaded brass to lead-free alternatives, with polished tungsten plates emerging as a prime candidate. Their durability and ability to withstand extreme conditions make them highly suitable for components that experience significant stress and friction.

Polished tungsten plates are gaining attention across various industries due to their exceptional properties, including high density, superior hardness, and excellent resistance to corrosion and wear. In hydraulic axial piston pumps, for instance, there is a growing shift from traditional leaded brass to lead-free alternatives, with polished tungsten plates emerging as a prime candidate. Their durability and ability to withstand extreme conditions make them highly suitable for components that experience significant stress and friction.

Tips: When considering polished tungsten plates for your applications, assess the specific mechanical requirements and environmental conditions your components will face. Additionally, ensure proper machining and finishing techniques are employed to maintain the material’s unique properties during fabrication.

Aside from hydraulic systems, polished tungsten plates find applications in electronics, aerospace, and medical devices, where precision and reliability are paramount. Their ability to effectively dissipate heat and resist deformation under pressure makes them ideal for high-performance environments. As industries move towards more sustainable practices, the adoption of lead-free materials like polished tungsten plates not only enhances product performance but also aligns with global efforts to reduce hazardous materials in manufacturing processes.

Comparative Analysis of Polished Tungsten Plates and Alternative Materials

Polished tungsten plates have gained significant attention in modern manufacturing due to their superior mechanical properties and versatility compared to alternative materials. Recent studies highlight that tungsten boasts an impressive tensile strength of approximately 1510 MPa, making it one of the strongest metals available. This strength, combined with a high melting point of around 3422°C, positions tungsten as an ideal candidate for applications in extreme environments, such as aerospace and high-temperature machinery, where other materials often fail.

In a comparative analysis, the adhesion characteristics of tungsten to substrates like titanium nitride have been explored using advanced molecular dynamics simulations. This research reveals that tungsten's ability to adhere strongly to various coatings enhances the durability and performance of manufactured components. Moreover, the use of spherical nanoindentation techniques allows for a detailed understanding of nanoscale damage and mechanical performance under ion irradiation, highlighting tungsten's resilience in challenging conditions. Given these attributes, polished tungsten plates emerge as a valuable alternative to traditional materials, offering an advantageous balance of strength, thermal stability, and adhesion capabilities in cutting-edge manufacturing processes.

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us

Polished

Polished