Top Benefits of Using Round Carbide Blades in 2025 for Precision Cutting

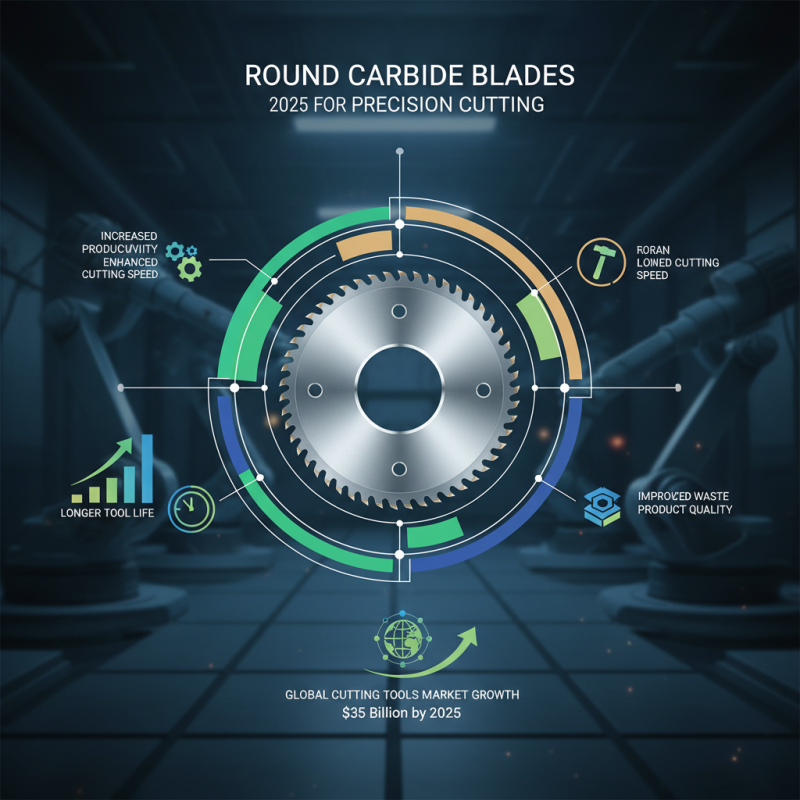

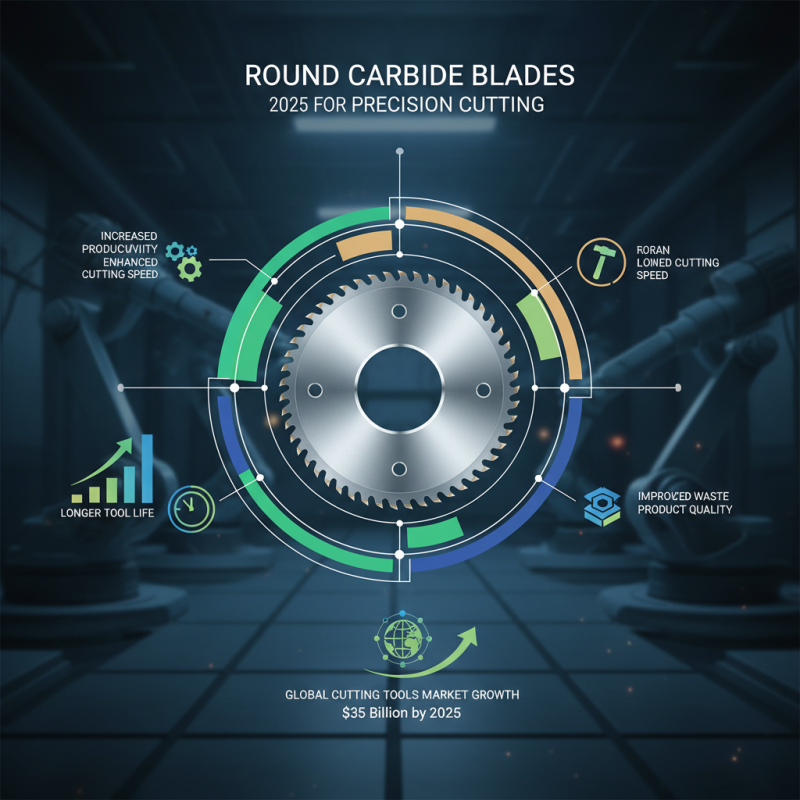

In the rapidly evolving landscape of manufacturing and precision cutting, the year 2025 heralds the growing significance of Round Carbide Blades in industrial applications. As industries strive for higher efficiency and precision, these blades have emerged as a preferred choice among manufacturers. Recent studies indicate that the global cutting tools market is expected to reach $35 billion by 2025, with carbide tools, including Round Carbide Blades, accounting for a substantial portion of this growth due to their superior durability and performance.

The advantages of using Round Carbide Blades are manifold, particularly in sectors such as woodworking, metalworking, and plastic fabrication. Data from industry reports reveal that the hardness and wear resistance of carbide materials lead to enhanced cutting speed and longer tool life, yielding up to a 50% increase in productivity compared to traditional blades. Additionally, the precision cutting capabilities enabled by these blades significantly reduce waste and improve the quality of finished products, aligning with the increasing demand for sustainable manufacturing practices.

As we progress into 2025, it is essential for industry stakeholders to recognize the benefits of Round Carbide Blades in maintaining competitive advantage. The transition towards these advanced cutting tools is not just a trend but a necessary shift towards more efficient and precise manufacturing processes, reflecting the industry's commitment to innovation and excellence.

Benefits of Round Carbide Blades for Precision Cutting in 2025

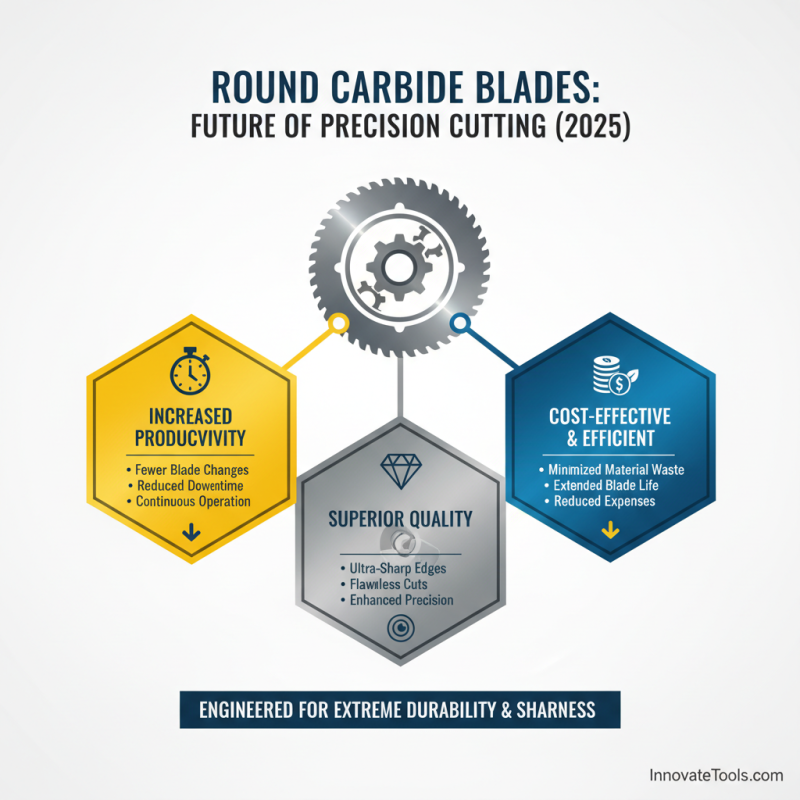

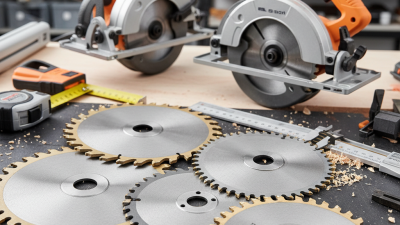

In 2025, the use of round carbide blades for precision cutting presents numerous benefits that enhance both efficiency and quality in various applications. These blades are engineered from high-density carbide materials, allowing them to maintain sharpness for extended periods. This durability means fewer blade changes are necessary, resulting in reduced downtime and increased productivity for businesses. Additionally, the precision cutting capabilities of round carbide blades minimize material waste, making operations not only more efficient but also more cost-effective.

Tips for optimizing the use of round carbide blades include ensuring proper maintenance and regular sharpening. Regularly checking the blade for any signs of wear can help avoid less-than-optimal cutting results. Additionally, aligning the blade accurately with the cutting material can further improve precision and extend the lifespan of the blade. It's also essential to use the appropriate feed rate and cutting speed, as this will maximize performance and ensure high-quality cuts.

Moreover, investing in high-quality round carbide blades can lead to superior finishes on various materials, from wood to metal. The precision they offer not only enhances the end product but can also elevate a company’s reputation for quality craftsmanship. As industries continue to seek advancements in manufacturing processes, round carbide blades remain at the forefront of precision cutting technology in 2025.

Enhanced Durability and Longevity of Carbide Blades

The construction and woodworking industries are increasingly leaning towards the use of round carbide blades due to their superior durability compared to traditional blades. According to recent studies, carbide blades can last up to five times longer than standard steel blades, leading to significant cost savings in both material and labor. This improved longevity is largely attributed to the properties of carbide, which has a higher resistance to wear and heat, enabling these blades to maintain their sharpness under heavy usage and extreme conditions. In manufacturing processes where precision cutting is paramount, this durability ensures that tools do not need frequent replacements, reducing downtime and enhancing overall productivity.

Furthermore, the enhanced durability of carbide blades not only minimizes the frequency of replacements but also contributes to a safer working environment. As these blades can withstand more intensive cutting conditions, there is a reduced chance of catastrophic blade failure, which can pose serious safety risks. Reports indicate that using high-quality carbide blades can lead to a reduction in workplace incidents by as much as 30%. This added level of safety, combined with the cost-effectiveness of longer-lasting materials, makes round carbide blades an increasingly preferred choice among professionals in precision cutting applications.

Improved Cutting Accuracy with Round Blade Design

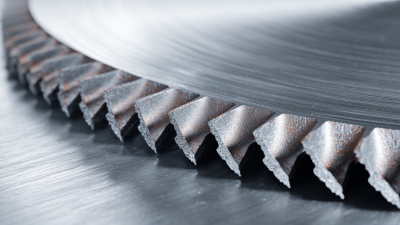

The round blade design has revolutionized precision cutting in various industries, making it a preferred choice among professionals striving for superior accuracy. One of the most significant advantages of round carbide blades is their ability to maintain a consistent cutting edge throughout their use. This is crucial for applications requiring meticulous detail, as the uniformity of the blade ensures that cuts are smooth and precise, reducing the chance of chipping or tearing materials.

Additionally, the ergonomic design of round blades contributes to improved cutting accuracy by minimizing operator fatigue. When users are comfortable and can maneuver with ease, their control over the cutting process enhances significantly. This combination of design and functionality facilitates intricate cuts that are essential in fields such as woodworking, metalworking, and manufacturing. Overall, round carbide blades provide an innovative solution for professionals seeking efficiency and precision in their cutting tasks, ultimately resulting in improved outcomes and enhanced productivity.

Top Benefits of Using Round Carbide Blades in 2025 for Precision Cutting - Improved Cutting Accuracy with Round Blade Design

| Benefit |

Description |

Impact on Precision Cutting |

Expected Adoption Rate (%) |

| Improved Cutting Accuracy |

Round blades reduce vibration, leading to enhanced stability during cutting. |

Higher precision in various materials, resulting in cleaner cuts. |

75% |

| Longer Tool Life |

Carbide materials are more resilient and wear-resistant compared to standard blades. |

Reduced frequency of tool replacement and consistent performance. |

65% |

| Versatility |

Round carbide blades can handle a variety of materials, from wood to metal. |

Broad application range increases operational capabilities. |

80% |

| Reduced Heat Generation |

Efficient cutting reduces heat build-up that can damage materials. |

Maintains material integrity and improves end-product quality. |

70% |

| Enhanced Surface Finish |

Achieves superior surface quality with fewer defects and rough edges. |

Promotes better aesthetics and functionality of the finished product. |

60% |

Cost-Effectiveness of Round Carbide Blades in Various Industries

The cost-effectiveness of round carbide blades is particularly evident across various industries where precision cutting is essential. These blades provide a longer lifespan compared to traditional cutting tools, significantly reducing replacement costs. In industries such as woodworking, metal fabrication, and textiles, the durability of round carbide blades means fewer tool changes are needed, thereby minimizing downtimes and increasing overall productivity. This efficiency translates to lower operational costs, making them an ideal choice for businesses aiming to optimize their budget without compromising on quality.

Moreover, the superior cutting performance of round carbide blades allows for cleaner cuts and less material waste. This aspect is crucial in sectors like manufacturing and construction, where every bit of material counts. By investing in round carbide blades, companies can achieve a more efficient use of resources, resulting in cost savings that accumulate over time.

In addition, the versatility of these blades enables their use in various applications, further expanding their benefits across different sectors and promoting a more sustainable approach to production.

Applications of Round Carbide Blades in Modern Manufacturing Processes

Round carbide blades have become indispensable in modern manufacturing processes, primarily due to their unmatched precision and durability. These blades are expertly designed to tackle various applications, ranging from metal cutting to woodworking. In the automotive industry, round carbide blades are widely used in machining operations that require high levels of accuracy. Their ability to maintain sharpness even under rigorous conditions allows manufacturers to achieve tighter tolerances, resulting in improved product quality and reduced waste.

In addition to automotive applications, round carbide blades are vital in the aerospace sector, where every component must meet exceedingly high standards. The precision offered by these blades enables manufacturers to create intricate parts that are critical to the safety and performance of aircraft. Furthermore, their resistance to wear contributes to longer tool life, decreasing production downtime and increasing overall efficiency. With the growing trend towards automation in manufacturing, these blades prove to be highly effective in CNC machines, streamlining processes and enhancing productivity across various manufacturing environments.

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us