Top 10 Best Carbide Round Bars for Precision Machining Applications?

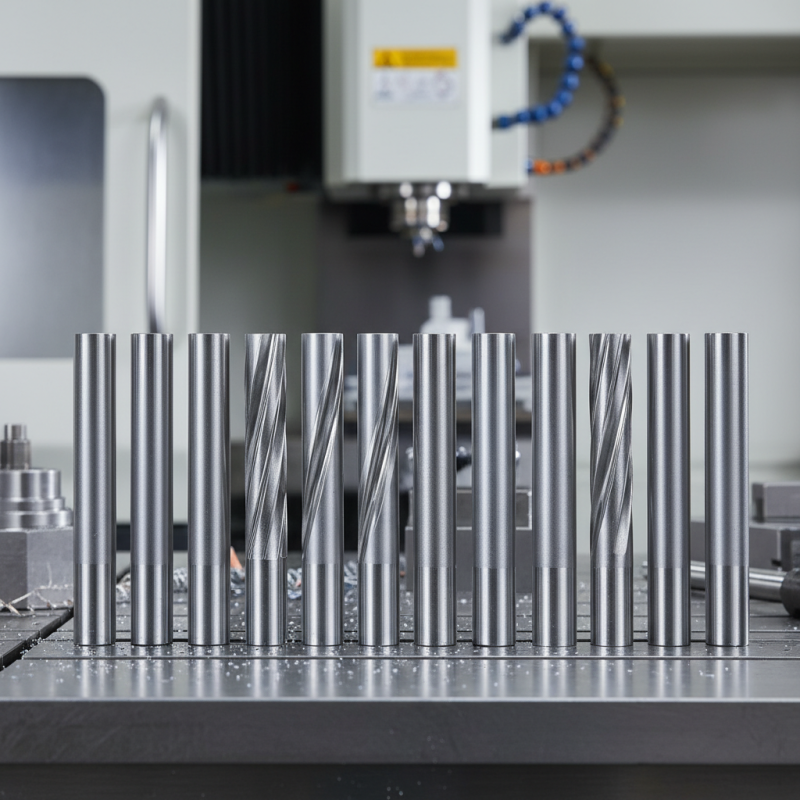

Carbide Round Bars have become essential components in precision machining. These tools provide excellent hardness and wear resistance. This quality makes them ideal for various applications in manufacturing.

In recent years, the demand for high-quality carbide round bars has surged. Industries rely on these tools to improve efficiency and accuracy. Selecting the right bars can significantly impact production outcomes. Factors such as size, grade, and quality are crucial.

However, not all carbide round bars perform equally well. Some may wear down faster than expected, causing delays. Users must carefully consider their options and invest in reliable products to avoid setbacks. Ultimately, the right choice can lead to superior machining performance and lasting results.

Importance of Carbide Round Bars in Precision Machining Applications

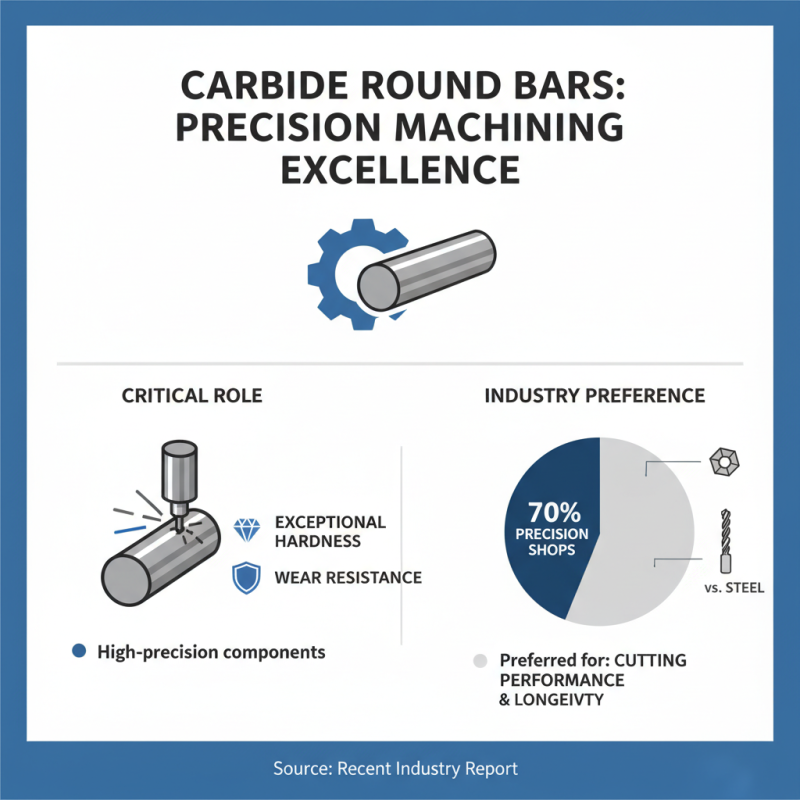

Carbide round bars play a critical role in precision machining applications. Their exceptional hardness and wear resistance make them ideal for producing high-precision components. According to a recent industry report, almost 70% of precision machining shops prefer carbide materials over traditional steel. This preference is due to the superior cutting performance and longevity carbide offers.

In machining, tolerances can be as tight as 0.001 inches. Carbide round bars can achieve these tolerances consistently. Many operators report reduced tool wear, which enhances production efficiency. However, not all carbide bars provide the same results. Some may chip or wear unevenly when pushed beyond their limits. A study indicated that about 15% of users encountered issues with subpar products, reinforcing the need for careful selection.

The demand for reliable carbide round bars continues to rise. Their versatility in applications such as aerospace and automotive is notable. However, operators should be wary of the quality. The potential for defects exists, and vigilance is crucial. Exploring various suppliers and conducting tests can prevent costly mistakes in production.

Key Properties and Specifications of High-Quality Carbide Round Bars

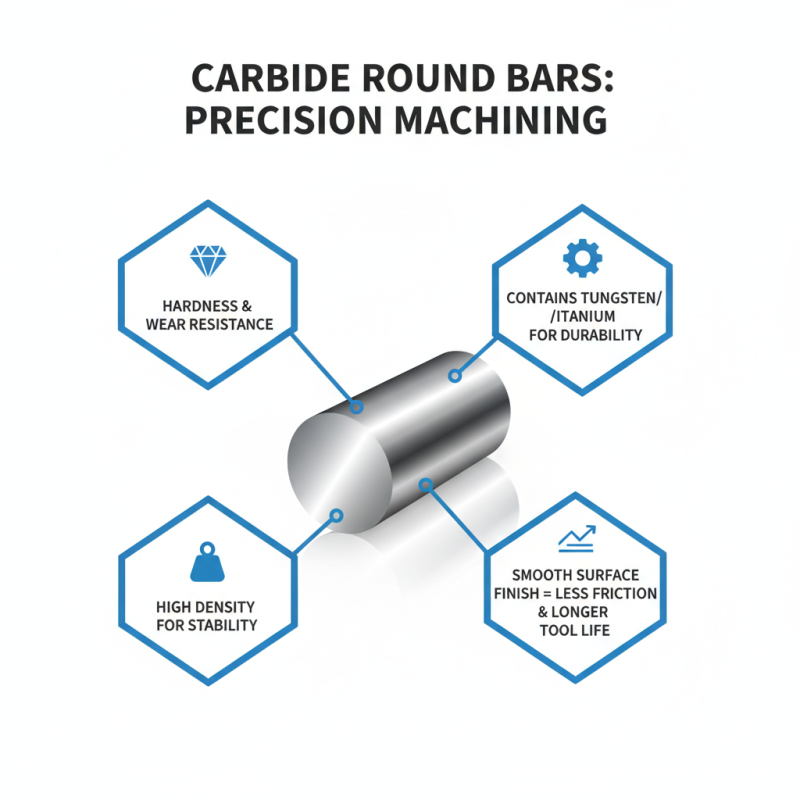

When considering carbide round bars for precision machining, one must focus on key properties. High-quality carbide is known for its hardness and wear resistance. This material often contains tungsten or titanium, enhancing its durability. A high density provides stability during machining, ensuring precision in every cut. The round bar's surface finish also plays a crucial role. A smooth finish minimizes friction and improves tool life.

Another vital specification is the diameter and length of the bars. These dimensions should align with specific machining requirements. For example, larger diameters may support heavier loads in demanding applications. Conversely, smaller sizes are ideal for intricate designs with tight tolerances. Additionally, machining parameters, like speed and feed rates, can significantly affect the performance of carbide round bars. Adjusting these factors may require trial and error.

It's essential to note that not all carbide round bars are created equal. Variations in cobalt content can impact toughness. While certain applications may require a harder bar, others might benefit from flexibility and shock resistance. Thus, understanding your specific needs is vital. This process involves careful consideration and sometimes reflection on past choices.

Top 10 Carbide Round Bars: Overview and Performance Metrics

Carbide round bars are essential in precision machining applications. Their hardness and wear resistance make them ideal for various industries. When selecting carbide bars, performance metrics matter a lot. These metrics include abrasion resistance, toughness, and workability. Each application may need different specifications.

Carefully consider the intended use of the bars. Are they for high-speed machining? Tougher grades of carbide might be necessary. If the focus is on surface finish, that changes the selection as well. Testing a few options can lead to better outcomes. Experience shows that not all carbide bars perform equally. Some may chip easily, while others maintain integrity under pressure.

Another aspect is the cost versus performance balance. Sometimes, higher price does not guarantee better quality. It's wise to research and gather user feedback. An ideal choice is one that meets your specific needs without excess spending. Every machinist should be prepared to adjust their choices based on practical outcomes. Experimentation can yield surprising insights.

Comparative Analysis of Leading Carbide Round Bar Brands

When exploring the world of carbide round bars, it’s essential to consider various factors that affect performance. A recent industry report revealed that carbide materials exhibit exceptional hardness, achieving up to 70 HRC. This hardness translates to significant wear resistance, making them ideal for precision machining applications. Users might find the consistency of these bars varies significantly between manufacturers, affecting machining efficiency.

Surface finish is another critical consideration. Research indicates that uneven surfaces can lead to vibration issues and poor cutting performance. Many users report that a rough finish can disrupt tool life, often leading to excessive wear. A finer surface finish may ensure greater accuracy during machining processes. Yet, not all brands prioritize this quality, resulting in a disparity in user satisfaction.

While evaluating brands, pay attention to production tolerances. Some manufacturers boast tolerances as tight as ±0.002 inches. However, others fall short, affecting end-user applications. Data shows that a mere 5% deviation can significantly impact high-precision tasks. As a result, discerning buyers need to carefully weigh these discrepancies to make informed decisions. The best carbide round bars should align with one's specific machining requirements.

Future Trends and Innovations in Carbide Round Bar Manufacturing

The carbide round bar manufacturing sector is evolving rapidly. Future trends are heavily influenced by precision machining applications. Reports project a growth in demand for high-performance materials. By 2025, the global carbide market is expected to reach $16 billion.

Innovations in manufacturing processes are a key focus. Advances in additive manufacturing have opened new possibilities. They allow for complex geometries that traditional methods cannot achieve. These new techniques reduce waste and improve efficiency. However, challenges remain. The need for skilled labor in these advanced techniques is pressing.

Sustainability is also becoming paramount. Companies are reevaluating their sourcing practices. There's a push for recycled materials in production. Statistics show that over 40% of manufacturers are investing in eco-friendly practices. Despite this progress, the industry must address gaps in waste management. The path forward is promising, yet it requires continuous improvement.

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us