The Best 10 Carbide Saw Blades for Precision Cutting in 2023

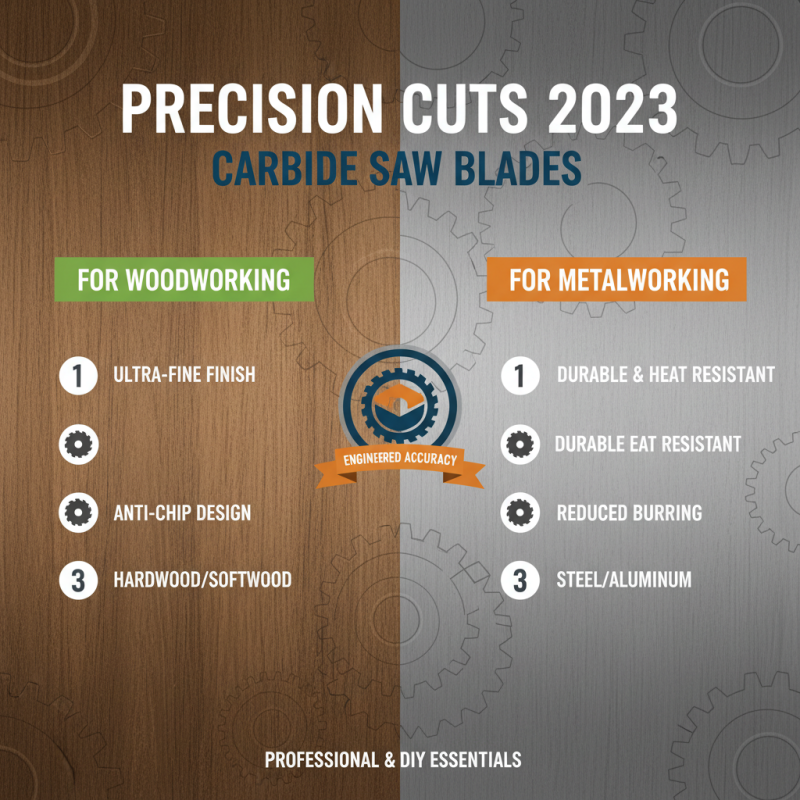

In the realm of woodworking and metal fabrication, carbide saw blades have emerged as the go-to solution for precision cutting in various applications. According to Dr. Steven Holloway, a leading expert in cutting tool technology, "The right carbide saw blade can make all the difference in achieving not just accuracy, but also efficiency in your projects." With advancements in manufacturing techniques and materials, today's carbide saw blades offer unmatched durability and sharpness, revolutionizing how professionals approach their cutting tasks.

As we delve into the best carbide saw blades of 2023, it's essential to understand the features that set these tools apart. From their ability to maintain sharpness over prolonged use to their resistance to wear and heat, the latest offerings in the market cater to diverse cutting needs. Whether for intricate woodworking or heavy-duty metal work, the selection of the perfect carbide saw blade can enhance both the quality of the cut and the overall efficiency of the job.

In this guide, we will explore the top ten carbide saw blades available today, highlighting their specifications, advantages, and ideal applications. By equipping yourself with the right knowledge about carbide saw blades, you can ensure that your cutting projects achieve the precision and success you desire.

Understanding Carbide Saw Blades and Their Benefits for Precision Cutting

Carbide saw blades are a vital tool for achieving precision cutting across various materials, including wood, metal, and composites. Their construction features a steel body with carbide tips that provide enhanced durability and longevity. This superior combination allows for cleaner cuts, reduced wear, and the ability to maintain sharpness over extended usage. Because of their precision, carbide saw blades minimize splintering and chipping, making them ideal for professional craftsmen and DIY enthusiasts alike.

The benefits of using carbide saw blades extend beyond mere cutting efficiency. Their ability to withstand high temperatures and resist dampening makes them particularly effective for heavy-duty applications, where conventional blades may falter. Additionally, the design of carbide tips allows for various tooth configurations tailored to different tasks, ensuring optimally smooth finishes. As a result, users experience increased productivity, reduced tool changes, and overall cost-effectiveness in their cutting operations. By understanding and utilizing carbide saw blades, individuals can significantly enhance their project outcomes with precise, reliable cuts.

The Best 10 Carbide Saw Blades for Precision Cutting in 2023

| Blade Type |

Diameter (Inches) |

Teeth Count |

Kerf (Inches) |

Best For |

Price Range (USD) |

| Crosscut Blade |

10 |

80 |

0.098 |

Wood |

$40 - $60 |

| Rip Blade |

10 |

24 |

0.125 |

Wood |

$30 - $50 |

| Plywood Blade |

12 |

96 |

0.090 |

Plywood |

$50 - $80 |

| General Purpose Blade |

10 |

40 |

0.110 |

Wood & Composite |

$35 - $55 |

| Miter Blade |

10 |

60 |

0.100 |

Miter Cuts |

$45 - $70 |

| Finishing Blade |

10 |

80 |

0.075 |

Finish Cuts |

$60 - $90 |

| Aluminum Blade |

10 |

40 |

0.100 |

Aluminum |

$50 - $75 |

| Thin Kerf Blade |

10 |

60 |

0.070 |

Wood & Composite |

$30 - $50 |

| Dado Blade |

8 |

24 |

0.125 |

Dado Cuts |

$70 - $100 |

| Stacked Dado Blade |

8 |

12 |

0.125 |

Dado Cuts |

$90 - $130 |

Key Features to Look for in Quality Carbide Saw Blades

When selecting carbide saw blades for precision cutting, there are several key features to consider that can greatly influence performance and longevity. First and foremost, the cutting geometry of the blade plays a critical role in achieving clean, accurate cuts. Blades with a higher tooth count tend to provide smoother finishes, while those with fewer teeth can cut more aggressively through thicker materials. Additionally, the hook angle of the teeth affects how the blade engages with the material; a positive hook angle can enhance the cutting speed but may sacrifice some finish quality.

Another important factor is the material and construction of the blade itself. High-quality carbide tips are essential for durability and resistance to wear, as they maintain sharpness longer than standard steel blades. The interaction between the body of the blade and its tips is also vital; lightweight yet robust construction can improve cutting efficiency and reduce fatigue for the user. Furthermore, features like laser-cut expansion slots and anti-vibration technology can minimize chatter, leading to more precise cuts and extending the life of the blade.

By carefully evaluating these elements, users can ensure they choose a carbide saw blade that meets their specific cutting needs and enhances overall project results.

Top 10 Carbide Saw Blades for Precision Cutting in 2023

In the realm of woodworking and metalworking, precision is paramount, and the right saw blade can make all the difference. Carbide saw blades have gained immense popularity due to their durability and capacity to provide clean cuts across various materials. In 2023, several standout options have emerged, tailored for professionals and DIY enthusiasts alike. These blades are meticulously engineered to reduce chipping and splintering, ensuring that each cut is not only accurate but also enhances the overall finish of the project.

The current top-rated carbide saw blades offer advanced features such as anti-vibration technology and improved tooth geometry, which collectively contribute to smoother operation and less wear over time. Whether tackling hardwood, softwood, or composites, these blades maintain sharpness and resist heat buildup, which is essential for long-lasting performance. Additionally, many of these blades are designed for compatibility with a range of saws, providing versatility for different applications. The combination of innovative design and premium materials presents users with options that not only meet but exceed expectations for precision cutting.

Comparative Analysis of the Best Carbide Saw Blades Available

When evaluating the best carbide saw blades for precision cutting in 2023, it's essential to conduct a comparative analysis of their performance metrics across various materials and applications. Recent industry reports indicate that carbide saw blades offer significant advantages over their traditional steel counterparts, primarily due to their superior hardness and wear resistance. According to a study by the International Cutting Tool Institute, carbide blades can maintain a cutting edge for up to three times longer than high-speed steel blades, making them a more cost-effective choice in both industrial and DIY settings.

In terms of cutting precision, the geometry of the carbide saw blade plays a pivotal role. Blades that feature alternate top bevel (ATB) teeth style are preferred for crosscuts in hardwood and softwood, while those designed with flat top grinding (FTG) teeth are more effective for ripping operations. Data from the Woodworking Machinery Manufacturers of America shows that utilizing the correct tooth geometry can improve cutting accuracy by nearly 30%, reducing the need for secondary operations. Moreover, blade diameter and tooth count significantly influence cutting efficiency and finish quality; blades with higher tooth counts typically produce smoother cuts, albeit at the cost of slower feed rates. By carefully considering these factors, users can select the optimal carbide saw blade suited for their precision cutting needs.

Tips for Maintaining and Maximizing the Lifespan of Saw Blades

Maintaining carbide saw blades is essential for achieving precision cutting and extending their lifespan. One of the most crucial tips is to keep the blades clean. Saw dust, resin, and other debris can accumulate on the teeth, leading to dullness and reduced cutting efficiency. Regularly cleaning the blades with a suitable solvent and a soft brush will help remove these contaminants. It's also important to inspect the blades for any signs of wear or damage, as early detection can prevent further deterioration.

Another key factor in maximizing the lifespan of carbide saw blades is proper storage. After use, blades should be stored in a dry environment, away from moisture and direct sunlight, to avoid rust and other forms of corrosion. Additionally, using blade guards or protective cases can help prevent accidental damage. When installing or removing blades from saws, taking care to avoid dropping them or subjecting them to unnecessary impacts is also critical, as this can lead to chips or cracks that compromise performance. By following these maintenance tips, users can ensure their carbide saw blades remain sharp and effective for longer.

The Best 10 Carbide Saw Blades for Precision Cutting in 2023

This bar chart illustrates the cutting performance of the top 10 carbide saw blades in 2023, measured in mm/s. Maintaining these blades correctly can enhance their lifespan and ensure precision cutting for various applications.

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us