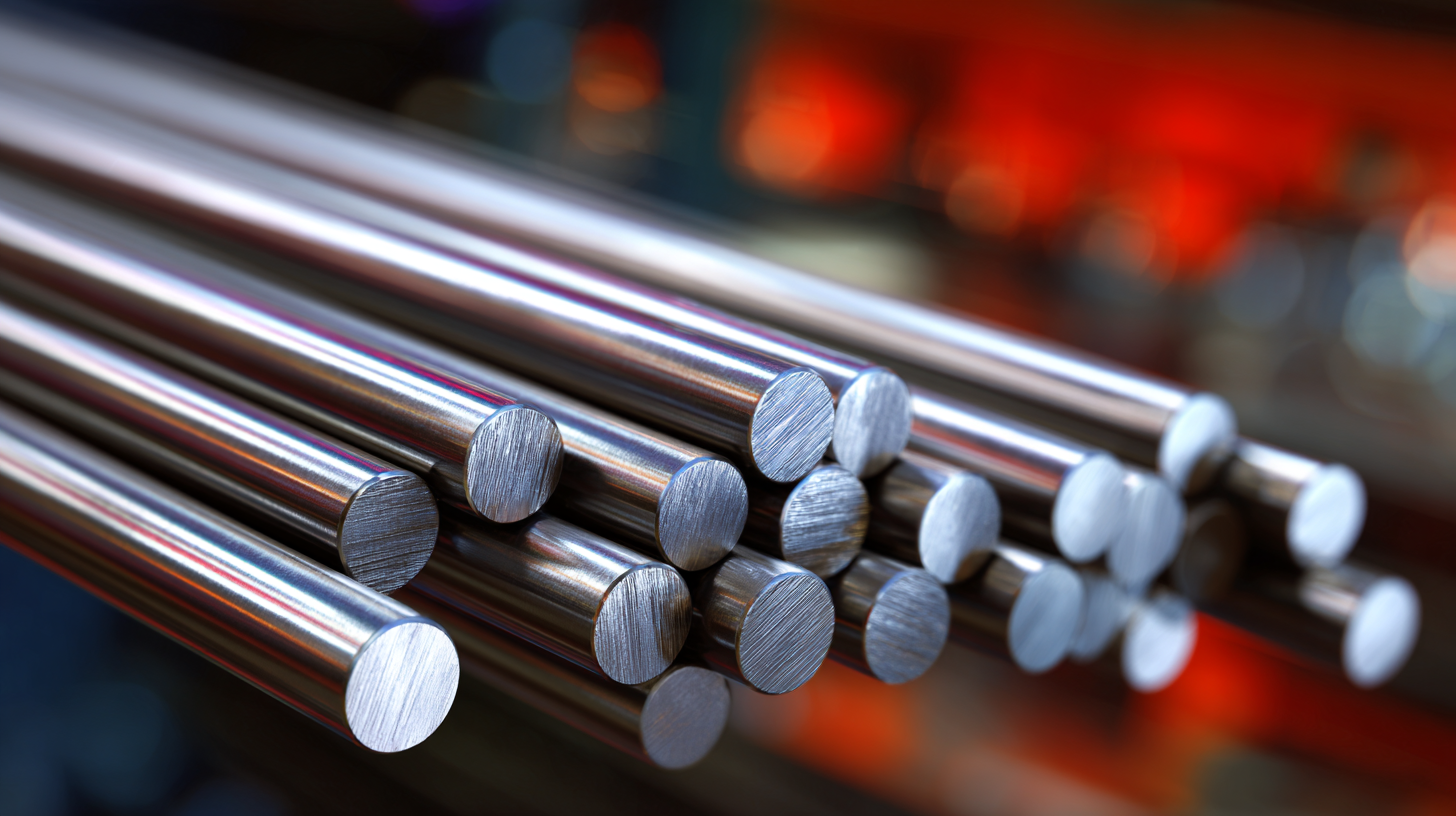

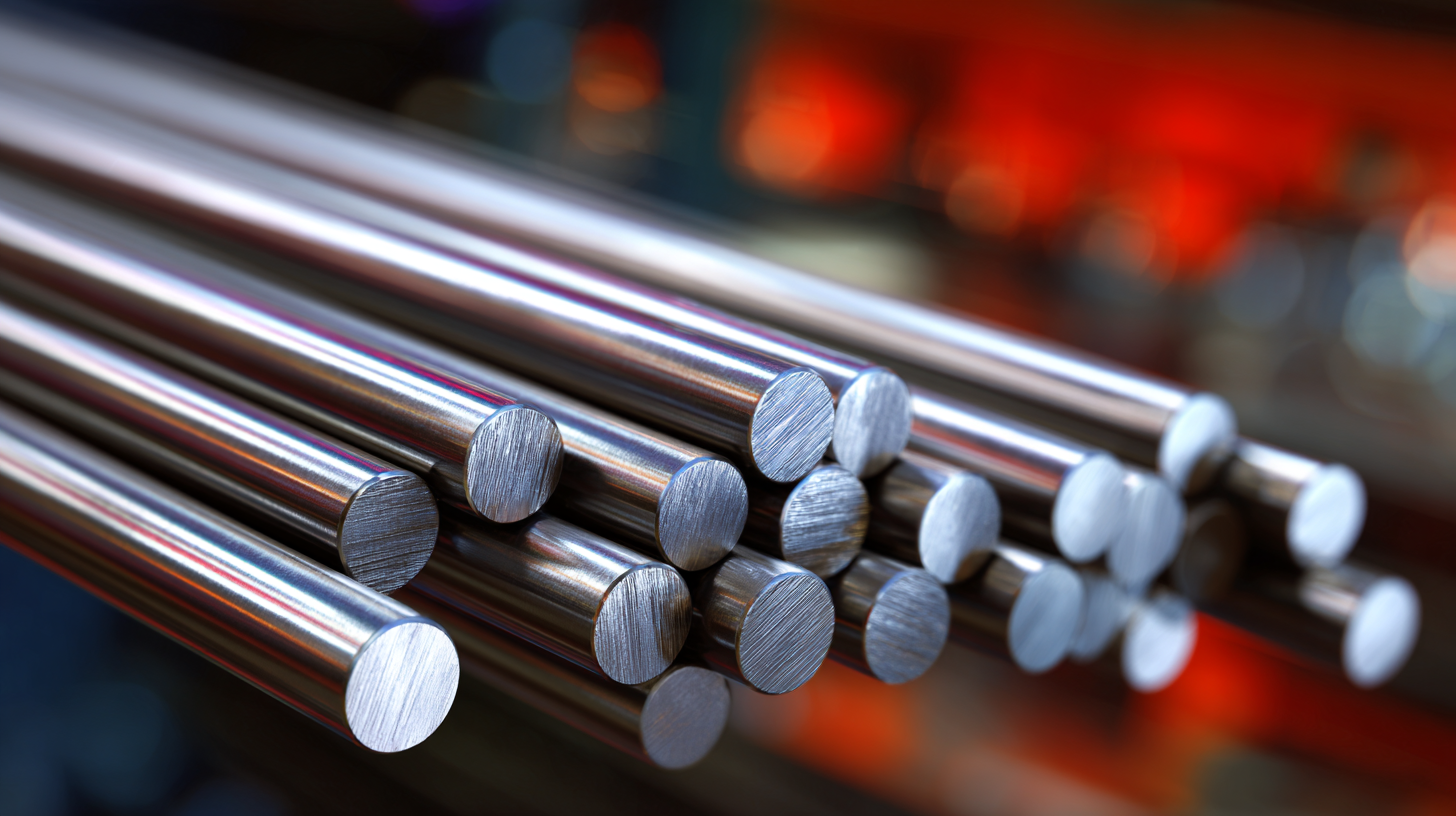

Exploring Carbide Blank Rods Innovations at the 138th China Import and Export Fair 2025

At the 138th China Import and Export Fair 2025, the spotlight will undoubtedly shine on innovations surrounding

Carbide Blank Rods, a pivotal component in various industries

such as manufacturing, automotive, and aerospace. According to a recent market analysis by

Industry Research Firm, the global carbide tools market is projected to reach USD 17.61 billion by 2026, demonstrating a

compound annual growth rate (CAGR) of 6.5%. This growth is heavily influenced by the increasing demand for

high-performance cutting tools, where Carbide Blank Rods play a crucial role due to their superior

hardness and wear resistance. Additionally, advancements in production technologies and materials science are further elevating the

capabilities and applications of these rods. As stakeholders gather at this prestigious fair, the exchange of knowledge and innovations

related to Carbide Blank Rods will be essential in shaping the future landscape of precision tooling and parts manufacturing.

Innovative Developments in Carbide Blank Rods for Enhanced Industrial Applications

At the upcoming 138th China Import and Export Fair in 2025, the focus on innovative developments in

carbide blank rods is anticipated to reveal significant advancements that cater to

enhanced industrial applications. Recent trends show a growing demand for carbide hard materials, driven by their exceptional hardness and

wear resistance, which is crucial for machining superalloys and other demanding materials. According to industry reports, the global carbide

tools market is projected to reach USD 21 billion by 2026, underscoring the importance of innovation in

this sector.

Among the notable advancements is a new grade of carbide rod blanks recognized for their outstanding performance in machining superalloys.

This innovation not only elevates efficiency but also improves the longevity of machining tools. Industry experts suggest that these developments

could lead to a substantial reduction in production costs and time, further optimizing processes across various sectors such as aerospace and

automotive manufacturing. As manufacturers continue to push the boundaries of material science, the introduction of these innovative carbide

blank rods at the fair is poised to set new benchmarks in the industry.

Key Industry Players Showcasing Their Latest Carbide Blank Rods at the Fair

The 138th China Import and Export Fair in 2025 is set to be a pivotal event for showcasing advancements in

carbide blank rods, attracting key industry players eager to present their latest innovations.

With the growing demand for high-performance materials, companies are focusing on developing superior tungsten carbide grades

that enhance machining efficiency, particularly in the processing of superalloys. Industry reports indicate that the market for carbide tools

is expected to grow significantly, driven by increased applications in Aerospace and Automotive sectors.

Among the notable exhibitors, advancements in carbide blank rods are being highlighted for their

superior wear resistance and longevity. Manufacturers are introducing specialized grades designed to withstand

high-temperature applications, which is crucial for industries demanding precision and reliability.

Recent innovations reflect a broader trend in optimizing material performance; reports suggest that new formulations can improve tool life

by over 30% compared to standard grades. This trend not only showcases the capabilities of modern carbide materials

but also reinforces the commitment of industry leaders to sustainability and efficiency in manufacturing processes.

Sustainable Manufacturing Practices in the Production of Carbide Blank Rods

At the 138th China Import and Export Fair 2025, a significant focus is placed on sustainable manufacturing practices in the production of carbide blank rods. As the demand for high-performance materials increases, manufacturers are exploring innovative methods to reduce environmental impact. This includes the use of eco-friendly sourcing for raw materials and energy-efficient production processes that minimize waste.

One transformative approach gaining traction involves recycling carbide scrap, which not only conserves valuable resources but also lowers production costs. By implementing closed-loop systems, companies can significantly enhance their sustainability credentials while maintaining product quality. Moreover, advancements in technology have allowed for precision manufacturing techniques that reduce energy consumption and optimize material usage, further contributing to a more sustainable production landscape. The fair serves as a platform for industry leaders to showcase these innovations, encouraging collaboration and knowledge sharing to propel the field toward greener practices.

Innovations in Carbide Blank Rods Production

This chart illustrates the comparison of production efficiency and sustainable practices in the manufacturing of carbide blank rods observed in 2025 at the 138th China Import and Export Fair.

Emerging Trends in Carbide Blank Rod Technology and Market Demand

The 138th China Import and Export Fair 2025 serves as a pivotal platform for showcasing the latest innovations in carbide blank rod technology. Emerging trends indicate a growing emphasis on enhancing the durability and performance of these rods, driven by increased demands from sectors such as automotive, aerospace, and manufacturing. With the push towards sustainable practices, manufacturers are also focusing on eco-friendly production methods and materials that reduce environmental impact while maintaining high quality.

Market demand for carbide blank rods is evolving quickly, with technological advancements leading to more efficient production processes and the introduction of smart manufacturing solutions. Companies are increasingly adopting automation and artificial intelligence to improve precision and reduce waste, positioning themselves competitively in a rapidly changing market. As suppliers and manufacturers gather at the fair, the exchange of ideas and innovations related to carbide blank rods will undoubtedly shape future trends and drive further enhancements in product offerings.

Networking Opportunities and Knowledge Sharing at the 138th China Import and Export Fair

The 138th China Import and Export Fair, set to showcase innovations in carbide blank rods, offers unparalleled networking opportunities and avenues for knowledge sharing amongst industry professionals. According to a recent market analysis report by ResearchAndMarkets.com, the global market for carbide blank rods is projected to reach USD 1.5 billion by 2027, growing at a CAGR of 5.2% from 2022. This growth is indicative of the rising demand for high-performance materials in various sectors, including aerospace, automotive, and manufacturing. Engaging in discussions and connections at the fair will be instrumental in understanding these market dynamics and fostering collaborations that can lead to technological advancements.

Attendees will have the chance to interact with thought leaders, engineers, and manufacturers who are at the forefront of innovation in carbide technologies. The fair will feature seminars and workshops that delve into recent developments in carbide manufacturing processes and applications. A report by Mordor Intelligence highlights that the increasing adoption of carbide tools is driven by their superior hardness and wear resistance, essential for improving operational efficiency. Networking at the fair will facilitate the exchange of ideas, best practices, and insights into optimizing production processes, ultimately benefiting the entire supply chain involved in carbide blank rod production.

Exploring Carbide Blank Rods Innovations at the 138th China Import and Export Fair 2025

| Innovation Type |

Description |

Key Advantages |

Application Areas |

| High Performance Carbide Rods |

Advanced carbide rods designed for superior wear resistance. |

Durability, improved machining efficiency, reduced tool wear. |

Aerospace, automotive, and precision engineering. |

| Nanostructured Carbide Blanks |

Blanks with nanoscale features for enhanced performance. |

Enhanced strength, toughness, and cutting efficiency. |

Manufacturing, mining, and oil drilling. |

| Eco-friendly Carbide Solutions |

Production methods that reduce environmental impact. |

Sustainable sourcing and reduced carbon footprint. |

Various industries focused on sustainability. |

| Custom Carbide Products |

Tailored carbide solutions to meet specific client needs. |

Personalized service, precise specifications, and enhanced performance. |

Tooling, aerospace, and electronics sectors. |

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us