What is a Carbide Ground Rod and How is it Used in Industries

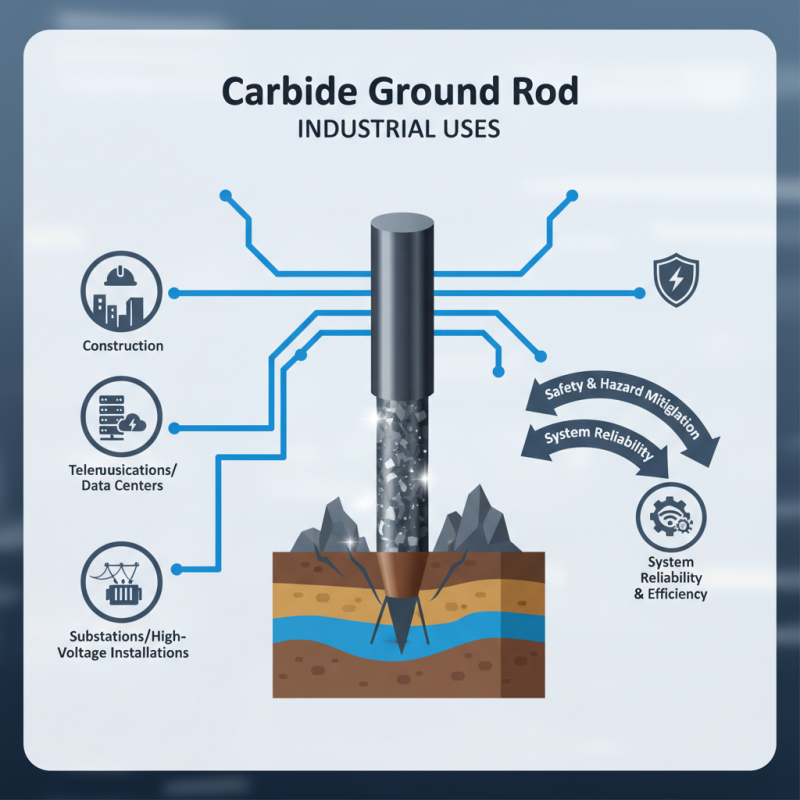

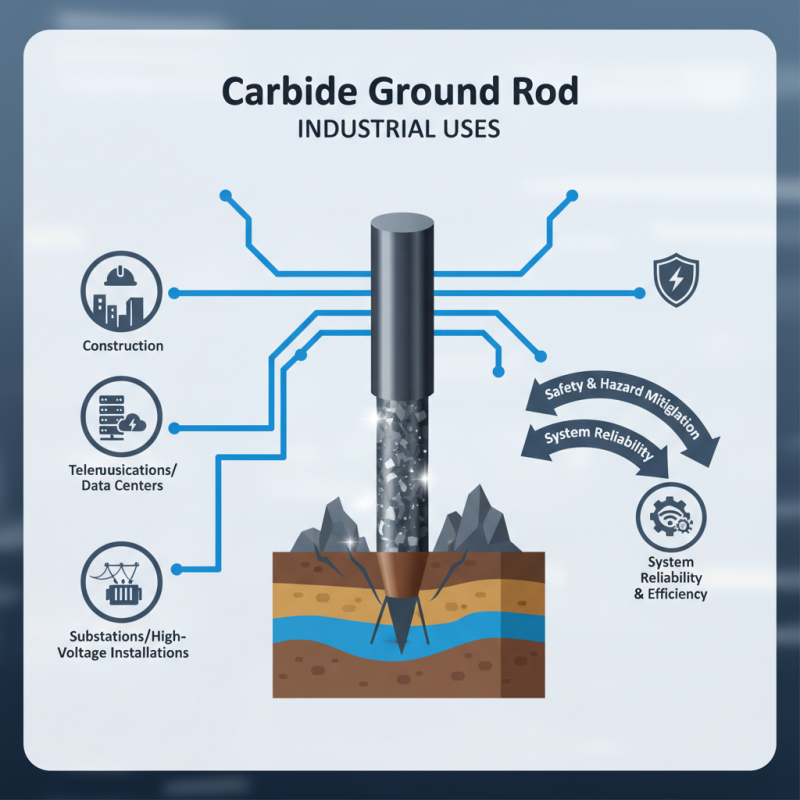

In the realm of industrial applications, the significance of grounding systems cannot be overstated, and one of the most effective components in these systems is the Carbide Ground Rod. Designed to provide reliable electrical grounding, carbide ground rods offer superior conductivity and corrosion resistance, making them a preferred choice in various sectors, from construction to telecommunications. The unique properties of carbide, a composite of carbon and a metal, enhance the performance of grounding systems, ensuring safety and efficacy in electrical installations.

As industries face increasing demands for robust grounding solutions to mitigate electrical hazards and enhance system reliability, the Carbide Ground Rod emerges as a vital player. Its durability and resilience under extreme environmental conditions make it ideal for use in diverse applications, including substations, data centers, and high-voltage installations. This introduction sets the stage for a deeper exploration of the functionality, advantages, and practical applications of carbide ground rods across different industries, highlighting their essential role in maintaining electrical safety and efficiency.

What is a Carbide Ground Rod?

Carbide ground rods are specialized tools made from tungsten carbide, a compound renowned for its hardness and wear resistance. These rods play a crucial role in various industrial applications, particularly in mining, construction, and machining industries. According to a report from Allied Market Research, the global market for tungsten carbide is projected to reach approximately $20 billion by 2025, reflecting the increasing adoption of carbide materials due to their superior performance characteristics.

In practical terms, carbide ground rods are utilized primarily for drilling and grinding operations. Their robust nature allows them to withstand high temperatures and abrasion, which are common in heavy-duty applications. For instance, a study by the International Journal of Advanced Manufacturing Technology found that carbide tools can outperform traditional steel tools by up to three times in terms of longevity and precision. This translates to significant cost savings and increased productivity for manufacturers, making carbide ground rods an essential component in high-efficiency processing environments.

Composition and Properties of Carbide Ground Rods

Carbide ground rods are essential components widely used in various industrial applications due to their superior hardness and wear resistance. Composed primarily of tungsten carbide, these rods exhibit exceptional physical properties, including a high melting point of approximately 2,870°C and impressive strength that enables them to withstand harsh conditions. According to a report from the International Tungsten Industry Association, tungsten carbide can be up to five times harder than steel, making it ideal for machining, mining, and construction operations.

In terms of composition, carbide ground rods typically consist of a mixture of tungsten and cobalt, which serves as a binder for the tungsten particles. This combination provides not only robustness but also improved toughness, critical for high-impact applications. The density of carbide ground rods is also notable, averaging around 15 g/cm³, which enhances their stability during use. Industry research from SME (Society of Manufacturing Engineers) indicates that the improved properties lead to longer tool life, reducing costs associated with tool replacement and maintenance in manufacturing settings. As industries continue to demand higher performance materials, the utilization of carbide ground rods is expected to rise significantly, highlighting their importance in modern engineering solutions.

What is a Carbide Ground Rod and How is it Used in Industries - Composition and Properties of Carbide Ground Rods

| Property |

Detail |

| Material Composition |

Typically composed of tungsten carbide and cobalt |

| Hardness |

High hardness level, often exceeding 80 HRA |

| Applications |

Used in mining, drilling, and manufacturing of precision tools |

| Corrosion Resistance |

Excellent resistance to wear and chemical degradation |

| Thermal Conductivity |

Good thermal conductivity, aiding in heat dissipation |

| Electrical Conductivity |

Generally low electrical conductivity, used as insulators |

| Manufacturing Process |

Produced through powder metallurgy and sintering techniques |

Applications of Carbide Ground Rods in Various Industries

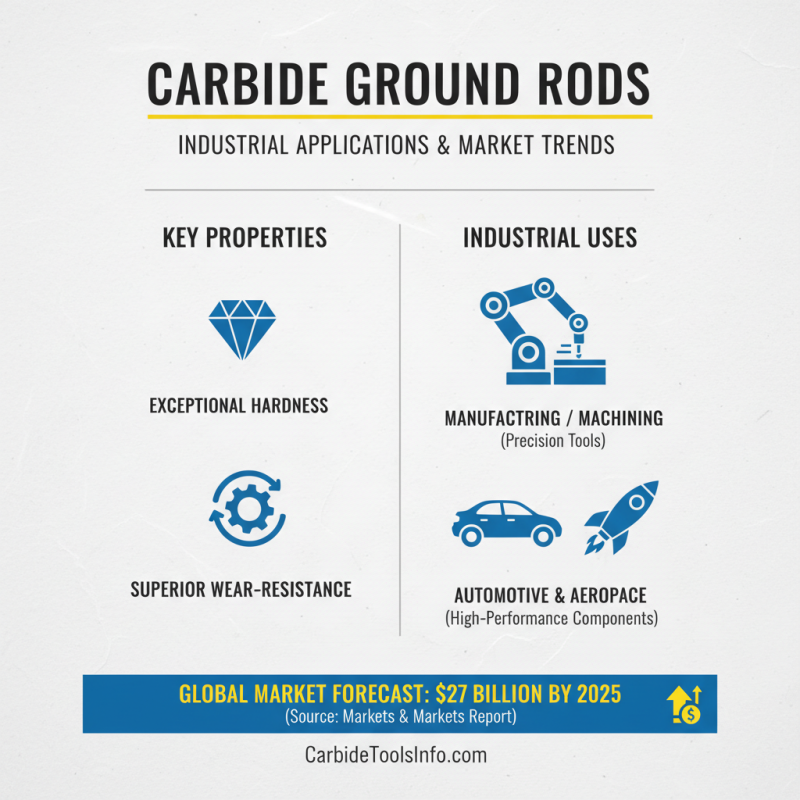

Carbide ground rods play a crucial role in various industrial applications, primarily due to their exceptional hardness and wear-resistance properties. In the manufacturing sector, these rods are frequently employed in machining processes where precision and durability are paramount. According to a report by Markets and Markets, the global market for carbide tools is expected to reach $27 billion by 2025, driven by the increasing demand for high-performance materials in industries such as automotive and aerospace.

In the construction industry, carbide ground rods are used as reinforcement for concrete applications. Their ability to withstand harsh environmental conditions makes them ideal for applications that require long-lasting structural integrity. A study published by the Journal of Materials in Civil Engineering indicated that incorporating carbide ground rods can enhance the tensile strength and overall durability of concrete mixes, thereby extending the lifespan of constructions. Additionally, the mining sector utilizes carbide ground rods in drill bits and other tools, where their toughness is essential for penetrating hard rock formations. This versatility underlines the significance of carbide ground rods across multiple industries, showcasing their critical contribution to advancements in material technology.

Advantages of Using Carbide Ground Rods Over Traditional Materials

Carbide ground rods have gained significant traction in various industries due to their superior performance compared to traditional materials like steel or copper. One of the most notable advantages is their exceptional wear resistance. According to a report by the International Materials Science Association, carbide materials can withstand wear up to five times longer than conventional alloys, leading to extended service life and reduced maintenance costs. This durability is particularly beneficial in harsh environments, where traditional rods would quickly degrade, resulting in downtime and increased operational expenses.

Moreover, carbide rods are more effective in electrical grounding applications. Their unique electrical properties allow for lower resistance paths, which is crucial in industries such as construction and telecommunications. The Electrical Safety Foundation International reported that utilizing carbide ground rods can improve grounding efficiency by up to 30%, thereby enhancing the overall safety and reliability of electrical systems. This increased efficiency not only minimizes the risk of equipment failure but also ensures compliance with stringent industry safety standards. As the demand for reliable and resilient materials continues to rise, carbide ground rods are proving to be a game-changer in industrial applications.

Installation and Maintenance Tips for Carbide Ground Rods

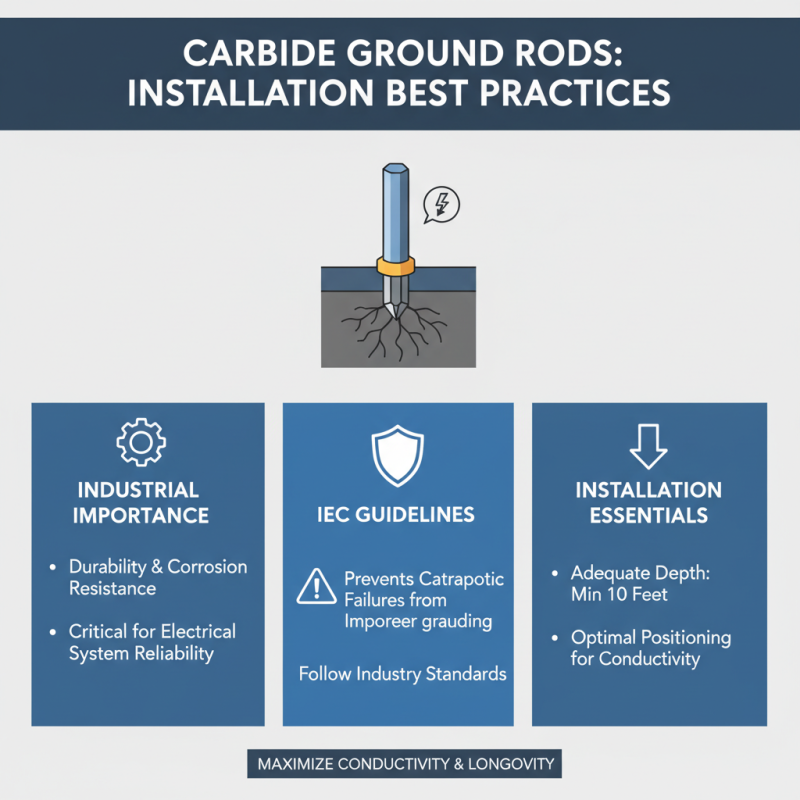

Carbide ground rods are essential components in various industrial applications, providing durability and resistance to corrosion. Proper installation and maintenance are key to ensuring their longevity and effectiveness. According to the International Electrotechnical Commission (IEC), improper grounding can lead to catastrophic failures in electrical systems, which highlights the importance of following industry best practices during installation. When installing carbide ground rods, it is crucial to follow specific guidelines such as ensuring adequate depth and positioning to maximize conductivity. A depth of at least 10 feet is often recommended to reach reliable soil conductivity, which can significantly reduce resistance and improve grounding efficiency.

Maintenance of carbide ground rods involves regular inspections and the removal of any corrosion or oxidation that may develop over time. The National Fire Protection Association (NFPA) suggests an annual checkup, particularly in environments prone to dust or moisture, which can accelerate deterioration. Testing the resistance of ground rods using a megohmmeter can help identify any issues before they lead to significant failures. By adhering to these maintenance protocols, industries can ensure that their grounding systems remain functional, thereby reducing the risk of equipment damage and enhancing safety measures in the workplace.

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us