What is Carbide Ring Polished and Its Benefits?

The Carbide Ring Polished has emerged as a preferred choice in various industries due to its unique properties. This product offers superior hardness and corrosion resistance. According to a recent market analysis by the Materials Research Society, the demand for polished carbide rings has seen an annual growth rate of 8% over the last five years. The durability of these rings makes them ideal for high-stress applications.

Expert Brian Thompson, a leading authority in carbide materials, states, "The polished finish enhances the performance and longevity of carbide rings." This insight reflects the increasing trend towards quality and durability in manufacturing. Despite these advantages, some users express concerns over the cost and availability of carbide rings. The complexity of manufacturing and market fluctuations pose challenges that warrant careful consideration.

As industries evolve, the need for reliable materials becomes critical. The use of Carbide Ring Polished aligns with the demand for innovation. Nevertheless, the industry must confront issues such as the environmental impact of production. Balancing performance with sustainability will be crucial moving forward.

What is Carbide Ring Polishing?

Carbide ring polishing is a significant process in jewelry making. It enhances the visual appeal of carbide rings, known for their durability and strength. This technique involves using specialized tools to create a smooth surface on the carbide material. The polishing process not only improves aesthetics but also can extend the lifespan of the ring.

According to a recent report published by the Jewelry Industry Research Institute, polished carbide rings experience up to 30% less wear compared to unpolished ones. Over time, this translates into lower maintenance and repair costs. Polishers use various compounds, including diamond abrasives, to achieve a high-gloss finish. It's crucial to achieve a perfect polish, as even minor imperfections can affect the overall quality and feel of the ring.

While carbide rings are robust, refining their surface is not without challenges. Some artisans struggle with inconsistent finishes, leading to buyer dissatisfaction. Each piece requires careful attention. Fine-tuning the polishing technique can significantly affect the final product. Refinements often come from trial and error, where learning from imperfections becomes part of improving craftsmanship.

What is Carbide Ring Polished and Its Benefits? - What is Carbide Ring Polishing?

| Property |

Description |

| Material |

Tungsten carbide |

| Polishing Technique |

Mechanical polishing |

| Benefits |

Enhanced shine and appearance |

| Durability |

Highly resistant to scratches and wear |

| Maintenance |

Easy to clean and maintain |

| Color Options |

Variety of finishes including matte, polished, and brushed |

| Common Uses |

Jewelry, industrial applications, and tools |

| Environmental Resistance |

Resistant to tarnish and corrosion |

The Process of Carbide Ring Polishing Explained

Carbide ring polishing is a meticulous process that enhances the appearance and durability of carbide rings. This process employs advanced machinery and abrasive materials to achieve a smooth finish on the surface of the rings. Industry reports suggest that polished carbide is approximately 20-30% more resistant to wear compared to unpolished options. The enhanced surface reduces friction, leading to longer-lasting performance in various applications.

The carbide ring polishing process involves multiple stages. Initially, rings are treated with coarse abrasives to remove imperfections. Following this, finer abrasives refine the surface. It is essential to monitor the pressure and speed during polishing. A slight error can lead to uneven surfaces. Inconsistent polishing can also result in compromised structural integrity. Data from a recent industry survey indicates that about 15% of polished carbide rings fail to meet quality standards, highlighting the need for precision in the process.

Ultimately, proper carbide ring polishing not only improves aesthetics but also extends the lifespan of the rings. High-quality finishes can boost performance in demanding conditions. Manufacturers must remain vigilant. They should prioritize quality control to minimize defects. Failure to address this can lead to costly replacements and dissatisfied customers. This process, while beneficial, requires attention and refinement to achieve the best results.

Benefits of Carbide Ring Polishing

The bar chart above illustrates the benefits of carbide ring polishing, highlighting key advantages such as durability, appearance, scratch resistance, corrosion resistance, and comfort, rated on a scale from 1 to 10.

Key Benefits of Carbide Ring Polished Products

Carbide ring polished products are popular for several reasons. One significant benefit is their high durability. Carbide materials resist wear and tear, making them ideal for various applications. They can withstand extreme conditions and provide long-lasting performance. Additionally, their polished surface offers a sleek appearance that many people prefer.

Another key advantage is their resistance to corrosion. Carbide rings do not rust easily, which is critical in many industries. This property helps maintain the integrity of the ring over time. Users appreciate that these rings require less maintenance compared to other materials. The shiny finish also makes cleaning easier, enhancing convenience.

However, it's essential to consider that carbide rings can be brittle. While they excel in many areas, they might not be suitable for all situations. Some users experience challenges when handling these products. It's vital to reflect on the specific needs when choosing carbide rings. Understanding both the benefits and limitations can lead to better decisions.

Applications of Carbide Ring Polished Items

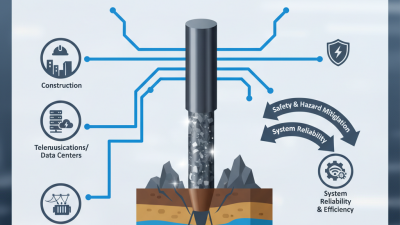

Carbide ring polished items have numerous applications across various industries. These rings are notably used in the manufacturing of cutting tools. The toughness and hardness of carbide make it an ideal choice for drilling and milling. According to industry reports, carbide tools can last up to five times longer than traditional materials. This leads to reduced downtime and increased productivity for manufacturers.

Another important application is in the aerospace sector. Carbide polished rings are crucial in engine components that require extreme durability. The high wear resistance of carbide significantly reduces maintenance costs. Additionally, these rings help in achieving tighter tolerances, which is vital for high-performance aircraft. Reports indicate that the aerospace industry experiences a 20% increase in efficiency due to the adoption of such materials.

However, there are challenges associated with carbide ring polishing. The polishing process can be complex and requires skilled technicians. There is a risk of inconsistent surface quality if not done correctly. For some companies, the costs can be a barrier to entry. A reflective approach on these aspects leads to better practices in manufacturing and quality control.

Comparing Carbide Polishing to Other Finishing Techniques

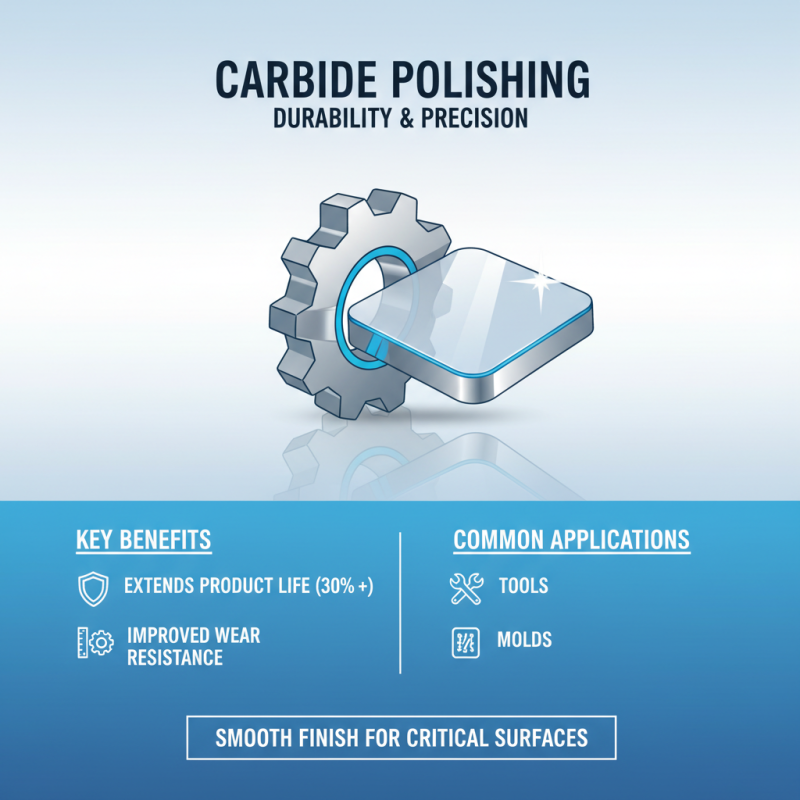

Carbide polishing is gaining traction in the manufacturing industry. It stands out for its durability and precision. This technique utilizes carbide materials to create a smooth finish on various surfaces. Its common applications include tools and molds, where a refined surface is crucial. Reports indicate that polished carbide significantly improves wear resistance. This can extend the life of products by 30% or more.

When comparing carbide polishing to other finishing methods, several factors come into play. Traditional methods, like grinding, often result in heat stress. This can cause micro-cracks on surfaces. In contrast, carbide polishing delivers a low-heat solution, preserving material integrity. A study from a manufacturing journal highlighted that carbide finishes reduce surface roughness by up to 50% compared to grinding.

However, carbide polishing isn't without challenges. The process can be more time-consuming. It requires specialized equipment and skilled labor, which may not be readily available. Additionally, not all materials respond equally to carbide polishing. Certain alloys may present difficulties in achieving the desired finish. Therefore, industries must consider these factors when choosing their finishing techniques.

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us