Unlocking the Secrets of Carbide Round Bars How They Enhance Tool Life and Performance in Manufacturing Industry

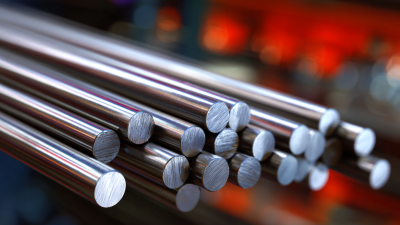

The manufacturing industry continuously seeks ways to improve efficiency and product quality, and one key innovation has been the development of

Carbide Round Bars.

These high-performance materials have gained significant traction due to their exceptional hardness and wear resistance, which can drastically enhance tool life and performance.

According to a recent report by Grand View Research, the global carbide tools market is expected to reach

USD 15.3 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.4%.

Carbide Round Bars play a pivotal role in this growth, as they are essential for producing cutting tools that withstand extreme conditions, ultimately reducing downtime and production costs.

As manufacturers strive to adopt advanced materials to remain competitive, understanding the benefits of Carbide Round Bars becomes increasingly crucial for achieving superior manufacturing processes.

Understanding Carbide Round Bars: Composition and Properties Essential for Manufacturing

Carbide round bars are essential components in the manufacturing industry, known for their exceptional hardness and wear resistance. Composed primarily of tungsten carbide, these bars exhibit remarkable durability, making them ideal for producing cutting tools and other machinery components. The unique composition of carbide round bars allows them to withstand extreme conditions and high temperatures, which significantly enhances tool life and performance. Understanding the properties of these bars is crucial for manufacturers aiming to optimize their operations.

When using carbide round bars, it's essential to consider proper tooling techniques. One useful tip is to ensure that the cutting speeds are adjusted according to the specific material being machined. This optimization not only prolongs tool life but also improves the overall efficiency of the manufacturing process. Additionally, maintaining the right balance between feed rates and cutting depths can help avoid unnecessary wear and tear on the tools.

Another important aspect to remember is the use of suitable coolant during machining. Implementing effective cooling techniques can significantly reduce friction and heat buildup, ultimately enhancing the performance of carbide tools. By paying attention to these factors, manufacturers can unlock the full potential of carbide round bars in their operations.

The Role of Carbide Round Bars in Tool Life Extension: Statistical Insights and Case Studies

Carbide round bars play a crucial role in enhancing the performance and longevity of tools used in the manufacturing industry. Statistical insights reveal that the application of carbide round bars significantly boosts tool life by reducing wear and tear. For instance, tools manufactured from carbide materials often exhibit a 20-50% increase in operational lifespan compared to those made from traditional steel. This marked improvement is attributed to carbide's superior hardness and resistance to high temperatures, which minimizes deformation and maintains sharpness during heavy machining operations.

Case studies further underscore the benefits of incorporating carbide round bars into tool designs. In one notable example, a manufacturing plant that switched to carbide-based tools for precision cutting reported a 35% increase in productivity due to reduced downtime for tool replacement. Additionally, this transition allowed the company to maintain tighter tolerances, leading to an overall enhancement in product quality. The evidence clearly demonstrates that investing in carbide round bars not only extends tool life but also contributes to significant performance gains in the manufacturing sector.

Unlocking the Secrets of Carbide Round Bars

| Dimension |

Material Composition (%) |

Rockwell Hardness (HRA) |

Average Tool Life (hours) |

Applications |

| 10 mm |

C: 6.2, W: 13.5, Co: 5.5 |

92 |

100 |

Drilling, Turning |

| 12 mm |

C: 6.0, W: 14.0, Co: 5.0 |

91 |

90 |

Milling, Boring |

| 16 mm |

C: 6.5, W: 12.0, Co: 6.0 |

93 |

110 |

Grinding, CNC Machining |

| 20 mm |

C: 7.0, W: 11.5, Co: 4.5 |

90 |

80 |

Sawing, Forming |

Performance Metrics: How Carbide Round Bars Outperform Traditional Materials in Manufacturing

Carbide round bars have emerged as a game-changer in the manufacturing industry, especially when evaluating performance metrics against traditional materials. Unlike steel or aluminum, carbide offers superior wear resistance, allowing tools made from this material to maintain their sharpness longer and reduce the frequency of replacements.

The hardness of carbide round bars significantly enhances their durability, which translates into extended tool life and increased productivity on the shop floor.

Carbide round bars have emerged as a game-changer in the manufacturing industry, especially when evaluating performance metrics against traditional materials. Unlike steel or aluminum, carbide offers superior wear resistance, allowing tools made from this material to maintain their sharpness longer and reduce the frequency of replacements.

The hardness of carbide round bars significantly enhances their durability, which translates into extended tool life and increased productivity on the shop floor.

Moreover, the thermal stability of carbide ensures that tools can withstand higher temperatures during machining processes without deforming. This capability allows manufacturers to operate at optimal cutting speeds and feeds, resulting in improved cycle times and overall efficiency.

When benchmarking against traditional materials, the lower friction coefficients of carbide further highlight its advantages, as it minimizes the heat generated during cutting operations, thereby preserving both the tool and the workpiece.

This performance superiority makes carbide round bars a critical choice for manufacturers aiming to optimize production and reduce operational costs.

Cost-Benefit Analysis: Investing in Carbide Round Bars for Long-Term Efficiency and Productivity

Investing in carbide round bars represents a strategic decision for manufacturers seeking to enhance long-term efficiency and productivity. Carbide materials are renowned for their exceptional hardness and wear resistance, which translates into extended tool life. By incorporating carbide round bars in machining processes, companies can significantly reduce tool replacements and downtime associated with wear-related failures. This not only contributes to smoother operations but also minimizes the overall cost of production over time.

A cost-benefit analysis reveals that the initial investment in carbide round bars often yields substantial savings in the long run. While the upfront cost may be higher compared to traditional tool materials, the enhanced performance and durability of carbide translate into lower operational costs. These savings come from decreased frequency of tool changes, reduced scrap rates, and improved machining efficiencies. Such benefits position manufacturers to capitalize on competitive advantages, allowing them to allocate resources more effectively and boost overall productivity in their operations.

Industry Innovations: Latest Developments in Carbide Round Bar Technology for Enhanced Performance

Recent advancements in carbide round bar technology have significantly transformed the manufacturing industry, particularly in enhancing tool life and performance. As manufacturers increasingly seek efficient and durable solutions, innovative approaches such as improved material formulations and precision processing methods are gaining traction. These developments not only optimize tool performance but also lead to cost savings and reduced downtime in production environments.

In parallel, the global silicon carbide semiconductor market is experiencing robust growth, projected to reach USD 11,783.1 million by 2033, with a compound annual growth rate of 18.5%. This surge is fueled by the rising demand for high-performance materials in various applications, including advanced steel processing techniques. Innovations in machining and welding are key drivers, enabling manufacturers to achieve greater efficiency and sustainability. As these technologies evolve, they play a crucial role in meeting the dynamic needs of the industry while minimizing environmental impact.

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us