How to Choose the Best Tungsten Carbide Round Bars?

When selecting the best Tungsten Carbide Round Bars, understanding the market intricacies is essential. According to a recent industry report by Global Market Insights, the demand for tungsten carbide products is expected to grow at a CAGR of 5.7% from 2023 to 2030. This highlights the importance of making informed choices in this competitive landscape.

Expert Dr. Emily Carter, a leading figure in material sciences, once stated, “Choosing the right tungsten carbide is not just about performance; it's about aligning with your specific application needs.” This underscores that not all Tungsten Carbide Round Bars are created equal. Factors such as hardness, corrosion resistance, and machining capabilities can significantly impact your project's success.

In a market filled with options, some may overlook critical specifications. The mishap of selecting the wrong grade can lead to increased costs and project delays. Industry professionals stress the value of detailed comparisons. It’s crucial to weigh your specific requirements against the available choices in Tungsten Carbide Round Bars. Every decision counts.

Understanding Tungsten Carbide: Properties and Applications

Tungsten carbide is a remarkable material, known for its exceptional hardness and durability. This composite is made of tungsten and carbon. Its hardness measures between 8.5 and 9 on the Mohs scale. This places it just below diamond. Tungsten carbide's unique properties make it ideal for demanding industrial applications. It is widely used in mining, manufacturing, and machining sectors.

The versatility of tungsten carbide extends to its applications. It’s commonly found in cutting tools, wear-resistant surfaces, and even jewelry. In machining, it helps improve efficiency and lifespan. Data from industry reports indicates that the global tungsten carbide market is expected to reach $21 billion by 2028. This growth reflects its increasing demand in various sectors.

However, there are challenges. Tungsten carbide can face brittleness, especially when subjected to extreme conditions. Proper selection is crucial for optimal performance. Not all tungsten carbide is created equal. The manufacturing process and grain size can affect its effectiveness. Buyers should consider these factors carefully. Effective knowledge about properties can lead to better material choices.

How to Choose the Best Tungsten Carbide Round Bars?

Key Factors to Consider When Choosing Tungsten Carbide Round Bars

When selecting tungsten carbide round bars, several key factors come into play. The diameter and length of the bars are crucial. Thicker bars may offer greater durability, while thinner ones can provide flexibility. You should assess the specific application before deciding.

Another vital factor is the grade of tungsten carbide. Different grades have varying hardness and wear resistance. Higher grades are typically more expensive, but they often deliver better performance. It’s essential to weigh cost against the expected lifespan.

Lastly, consider the manufacturer’s reputation. Quality control can differ significantly among producers. Researching who makes the bars can help guide your decision. Even well-known manufacturers may have inconsistencies. It’s wise to seek feedback and aim for the best possible choice, despite the potential for selected materials to fail at times. The balance between quality and price can be challenging. Always reflect on what works best for your specific needs.

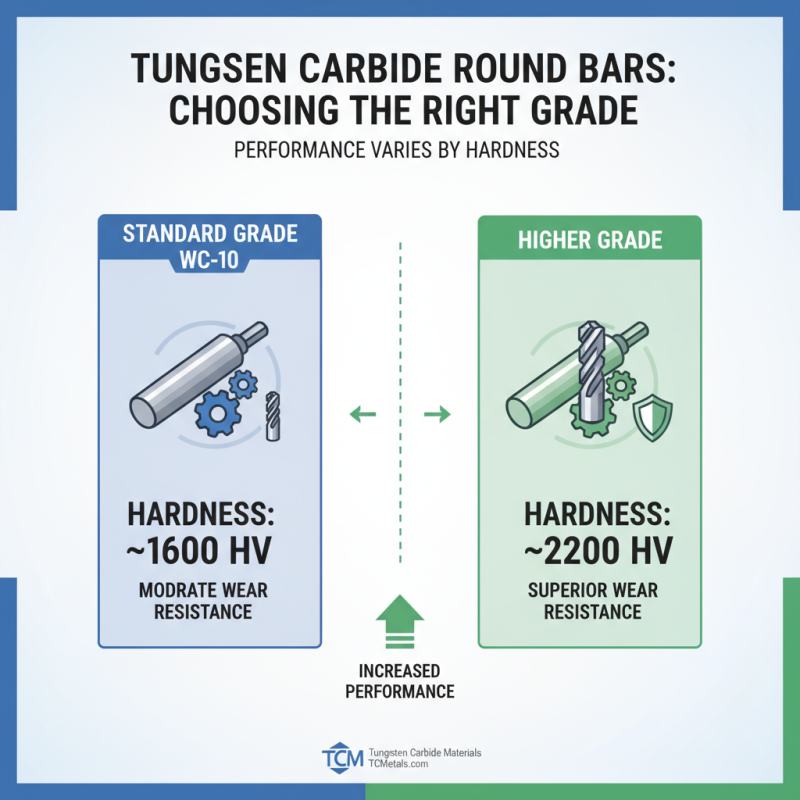

Comparative Analysis of Different Tungsten Carbide Grades

When selecting tungsten carbide round bars, understanding the differences in grades is crucial. Each grade offers unique properties affecting performance. For instance, the hardness of tungsten carbide can significantly vary. A standard grade, known as grade WC-10, typically has a hardness of around 1600 HV. In contrast, higher-grade options can reach about 2200 HV. This indicates a significant increase in wear resistance.

Industry data shows that choosing the right grade impacts efficiency. A study by the International Hard Materials Association revealed that using a higher grade can increase tool life by up to 50%. However, this comes at a higher cost. Evaluating your material needs is essential. Sometimes, a mid-grade option could suffice, saving budget without sacrificing quality.

Additionally, not all tungsten carbide bars are created equal. Variations in binder materials—like cobalt or nickel—can change toughness and brittleness. Grades that incorporate cobalt often exhibit better shock resistance. But, this can lead to more deformation under high stress. It poses a dilemma for engineers: prioritize hardness or toughness? Finding balance is always a challenge. Thoughtful consideration is key when selecting the right tungsten carbide grade for your applications.

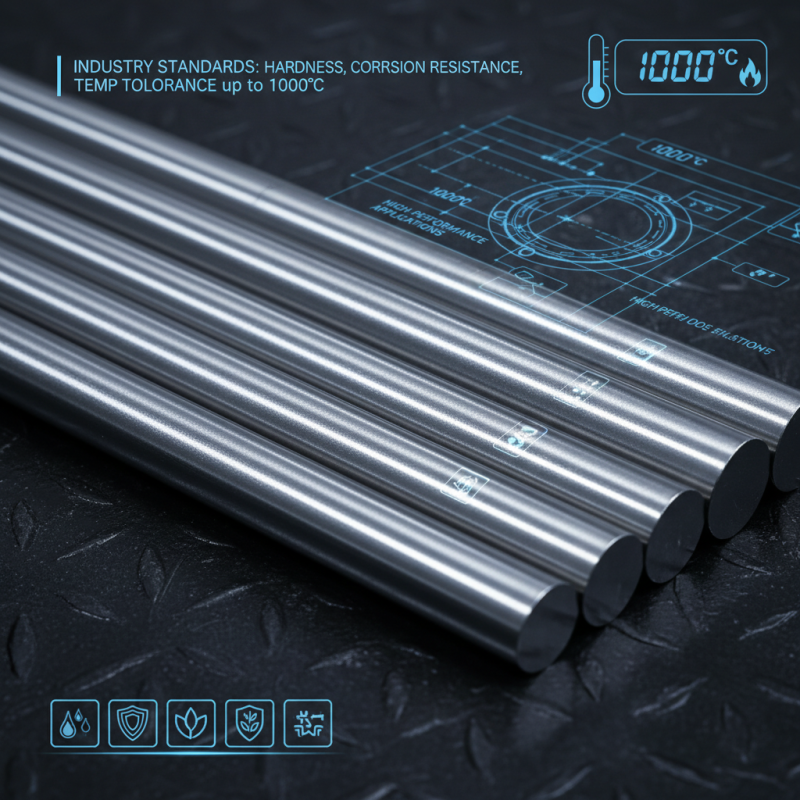

Industry Standards for Tungsten Carbide Round Bars Selection

When selecting tungsten carbide round bars, understanding industry standards is essential. The hardness, corrosion resistance, and temperature tolerance of these materials matter greatly. Industry reports indicate that tungsten carbide can withstand temperatures up to 1,000 degrees Celsius. This makes it suitable for high-performance applications in various sectors. However, not all tungsten carbide is created equal.

The American Society for Testing and Materials (ASTM) provides guidelines for minimum standards. These include wear resistance measures and material composition analysis. High-quality round bars should meet ASTM C tungsten carbide standards. Reports show that failure to adhere to these standards can lead to premature wear and increased operational costs.

A notable detail often overlooked is the dimensional accuracy of round bars. Tolerance levels must align with specific applications. A large discrepancy can render the product ineffective. The exact diameter or length contributes to the overall performance. It's vital to consider these specifications seriously to avoid costly mistakes down the line.

Cost-Effectiveness: Evaluating Price vs. Performance in Tungsten Carbide

When selecting tungsten carbide round bars, cost-effectiveness plays a crucial role. Evaluating price versus performance can be challenging. Some products may appear cheaper but might not deliver the same durability or efficiency. A deep analysis is necessary.

Assess materials used for the bars. High-quality tungsten carbide often justifies a higher price. Consider factors like wear resistance and hardness. Sometimes, more affordable options wear out quickly. This can lead to operational delays and unexpected costs.

Think about the application for the bars. Specific industries may demand precision and longevity. A lower upfront cost may result in higher expenditures over time. The trade-off between initial savings and long-term performance can be significant. Reflect on how often the bars will be used. Sometimes, spending more now can save money later.

How to Choose the Best Tungsten Carbide Round Bars? - Cost-Effectiveness: Evaluating Price vs. Performance in Tungsten Carbide

| Grade |

Density (g/cm³) |

Hardness (HRA) |

Tensile Strength (MPa) |

Price per kg ($) |

Performance Rating (0-10) |

| TC10 |

14.95 |

91.0 |

2200 |

25 |

8 |

| TC20 |

14.85 |

90.5 |

2400 |

30 |

9 |

| TC30 |

14.75 |

89.0 |

2600 |

35 |

9.5 |

| TC40 |

14.60 |

88.0 |

2800 |

40 |

10 |

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us