Why Choose Carbide Saw Blades for Your Cutting Needs?

Carbide saw blades are a popular choice in the cutting industry. They offer distinct advantages over traditional blades. These blades are crafted from a durable material, ensuring longevity. Their ability to withstand high heat makes them ideal for tough materials.

When you select carbide saw blades, you invest in precision and efficiency. They provide clean cuts, reducing the need for additional finishing. Many users appreciate the cost savings from longer blade life. However, it’s crucial to handle them with care. Improper use can lead to premature wear or damage.

Understanding your cutting needs is essential when choosing blades. Some may find that carbide saw blades excel in specific applications. Additionally, experimenting with various materials can be enlightening. It's important to regularly reflect on your choices to ensure optimal performance.

Understanding Carbide Saw Blades: Composition and Properties

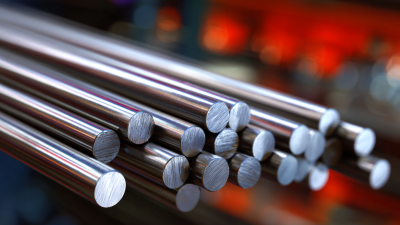

Carbide saw blades are becoming a popular choice in various industries. Their unique composition makes them highly effective for cutting hard materials. Typically, carbide blades are made from tungsten carbide particles, bonded with cobalt. This combination provides exceptional durability and hardness, which translates to longer cutting life.

These blades exhibit superior wear resistance. They can maintain sharp edges longer than traditional steel blades. According to industry reports, carbide blades can outlast high-speed steel blades by up to 15 times. This longevity results in less frequent replacements and lower operational costs. Their ability to cut through hardwoods and composites makes them invaluable for serious woodworkers.

Tip: Always choose a blade that matches your specific cutting material. This ensures optimal performance and fewer accidents.

Despite their many advantages, selecting the right carbide blade can be confusing. Not all applications require the same type of blade. It’s crucial to consider thickness and tooth configuration. Improper selection can lead to inefficient cutting and increased wear.

Tip: Pay attention to the recommended RPM for your blade. Exceeding this can cause damage and decreased effectiveness.

Advantages of Using Carbide Saw Blades Over Other Materials

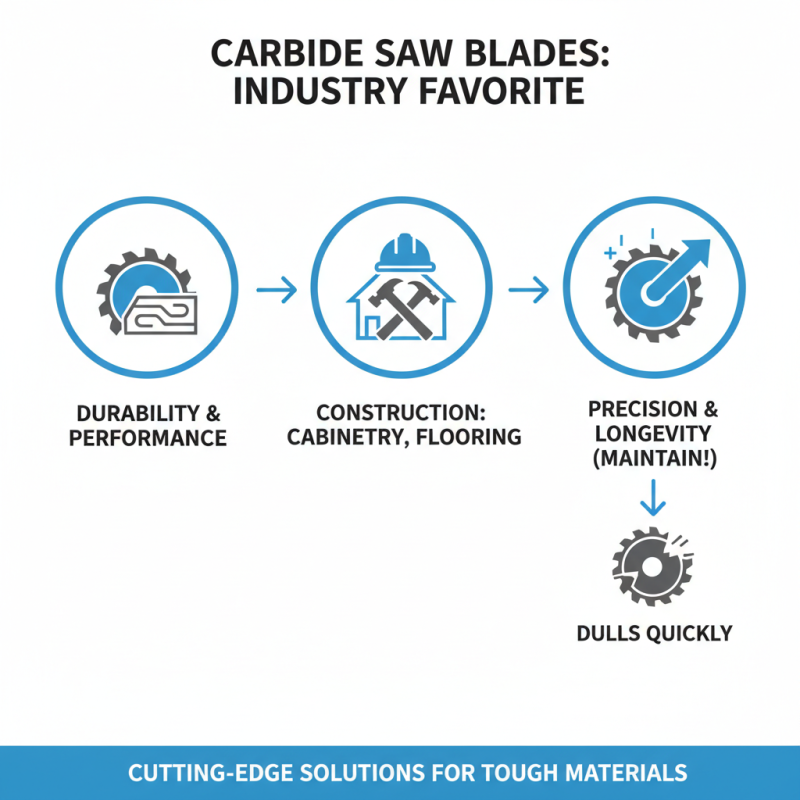

Carbide saw blades have become the go-to choice for many cutting tasks. One major advantage is their durability. These blades can withstand heavy use without losing their edge quickly. This means they often outlast steel blades, making them a smart investment. Users notice fewer replacements over time, leading to cost savings.

Another significant benefit is precision. Carbide saw blades cut through various materials smoothly. From hardwood to soft plastics, their sharpness ensures clean cuts with minimal splintering. This level of precision can elevate the quality of any project. However, users may occasionally face challenges; improper handling can lead to blade damage. Understanding proper use is essential.

Moreover, carbide blades perform well at high speeds. This feature is important for professionals who require efficiency. While they excel in many scenarios, it’s crucial to note they may be overkill for simple tasks. Sometimes, a basic blade suffices. Weighing the specific job's demands against the blade's capability is key for success.

Applications of Carbide Saw Blades in Various Industries

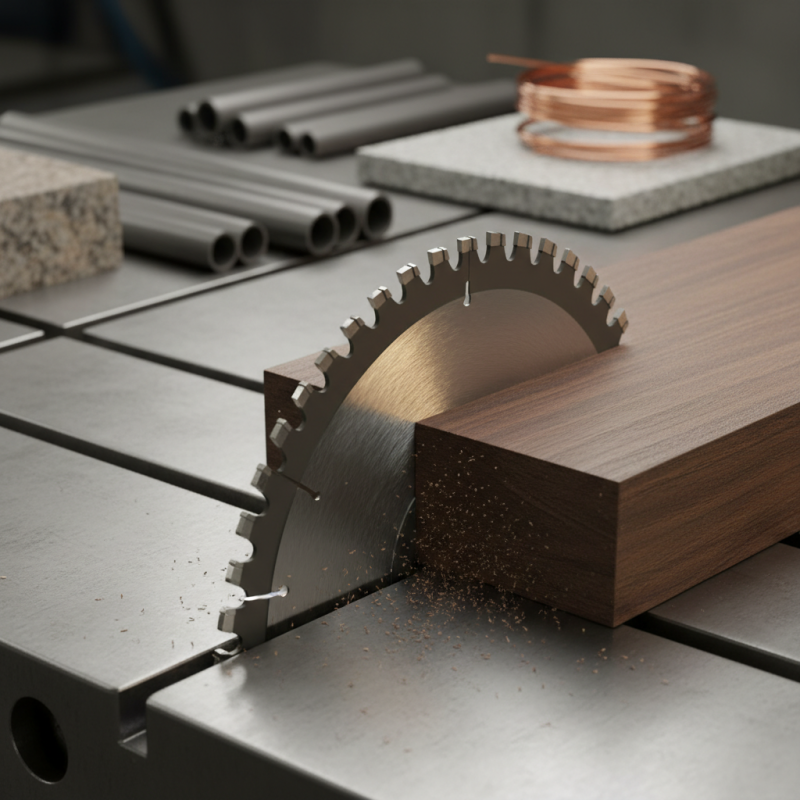

Carbide saw blades are favored in many industries due to their durability and performance. In construction, they cut through tough materials like plywood and engineered wood. This makes them crucial for framing, cabinetry, and flooring tasks. A sharp blade can enhance precision, but it can dull quickly if not maintained.

In metalworking, these blades are also common. They efficiently cut through aluminum, steel, and other metals. However, overheating can occur without proper cooling. Users often overlook the need for regular checks on blade temperature. The balance between speed and precision is vital in this application.

In the plastics industry, carbide blades offer clean cuts. They help shape parts with smooth edges. Yet, too much pressure during cutting can lead to poor results. This highlights the need for skilled operators who understand material characteristics. Overall, carbide saw blades play a significant role across various sectors, although they require careful handling to achieve the best results.

Maintenance Tips for Prolonging the Life of Carbide Saw Blades

Carbide saw blades are increasingly popular for their durability and efficiency. However, proper maintenance is vital for maximizing their lifespan. According to industry reports, regular maintenance can increase the lifespan of these blades by up to 50%. Neglecting care leads to faster wear and tear, presenting significant costs in replacements.

To ensure your blades last, consider these tips:

First, always clean saw blades after use. Residue buildup can degrade cutting performance. A simple solution is to soak blades in a warm, soapy water mixture, then scrub gently.

Second, store your blades properly. They should be kept in a dry place with protective sheaths. This prevents accidental damage and rust formation.

Regular inspections are crucial. Check for any chips or dullness before you start. If the edge looks worn, it’s time for sharpening. A sharp blade cuts cleanly and is safer to use. Investing time in maintenance can save costs in the long run. Remember, well-kept blades lead to smoother cuts and fewer headaches.

Cost Considerations: Investing in Carbide Saw Blades for Efficiency

When considering cutting tools, carbide saw blades emerge as a reliable choice. They are known for their durability and efficiency. According to industry reports, the lifespan of carbide blades is significantly longer than standard blades. In fact, these can last up to 10 times longer, reducing costs over time. This is crucial for businesses aiming to optimize spending while maximizing productivity.

While carbide saw blades have a higher upfront cost, the investment pays off. The National Association of Manufacturers highlights that companies using carbide tools have reported a 25% decrease in operating costs. This is partially due to fewer blade replacements and reduced downtime. However, it’s essential to consider usage. Not every application suits carbide. Some material types may cause faster wear. Therefore, careful evaluation is crucial.

The initial investment in carbide saw blades can be daunting. Yet, the long-term savings and efficiency gains are hard to ignore. Selecting the right type of blade for the specific task is vital. It ensures optimal performance and value. A mismatch can lead to increased costs and inefficiency. It's a balancing act, one that requires careful planning and insight into operational needs.

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us