How to Choose the Right Carbide Flat for Your Machining Needs?

Choosing the right carbide flat for your machining needs can be challenging. According to John Smith, a seasoned expert in the carbide industry, "The right carbide flat can significantly enhance your machining efficiency." This statement underscores the importance of making an informed choice.

Carbide flats come in various shapes, sizes, and grades. Selecting the proper one requires careful consideration of the specific application. For instance, hardness and wear resistance are crucial factors. However, many overlook these details, leading to suboptimal performance and unnecessary costs.

It’s essential to examine your machining requirements closely. Consider the materials you will work with and your desired finish quality. Remember, a poorly chosen carbide flat can negatively impact your overall project. Reflect on your selection criteria to ensure you make the best decision for your needs.

Understanding Carbide Flats and Their Applications in Machining

Carbide flats are essential in machining. These tools are made from tungsten carbide, known for its hardness and durability. Their ability to withstand high temperatures makes them important in various applications. They are commonly used for cutting, shaping, and finishing materials. These tasks require precision and strength, and carbide flats deliver just that.

Choosing the right carbide flat can be confusing. It's important to consider the specific needs of your project. Different sizes and shapes can affect performance significantly. The thickness and width must match the job requirements. A flat that is too thick may not fit into tight spaces. A thinner one might not last through tough materials. Reflecting on your choices can help ensure optimal results.

Understanding the applications of carbide flats is crucial. They are used in industries like aerospace and automotive. Each industry demands different specifications and tolerances. Using the wrong carbide flat can lead to ineffective machining and wasted resources. Investing time in understanding your requirements can save you from costly mistakes. Making informed decisions is vital for efficiency in machining.

Key Factors to Consider When Choosing a Carbide Flat

When selecting a carbide flat for your machining tasks, various factors should be considered. The type of material you plan to work with is crucial. Different carbides perform uniquely based on the material properties. For example, harder materials may require more robust carbide flats. It’s also important to assess the taper and thickness of the carbide. Thinner flats can provide precision but may lack durability.

Surface finish plays a significant role in functionality. A smoother finish typically allows for better performance and reduced friction. However, some applications might benefit from a rougher surface. This trade-off often requires deeper reflection on your specific needs. Another consideration is the geometry of the carbide flat. The tool’s angles and contours can affect chip removal and efficiency during machining.

Don’t overlook the importance of the tool's overall design. The right design can lead to improved longevity and reduced waste. Sometimes, it’s hard to predict performance until you’ve done several tests. This factor can lead to multiple iterations before achieving the desired outcome. Make sure to keep an open mind and learn from each trial.

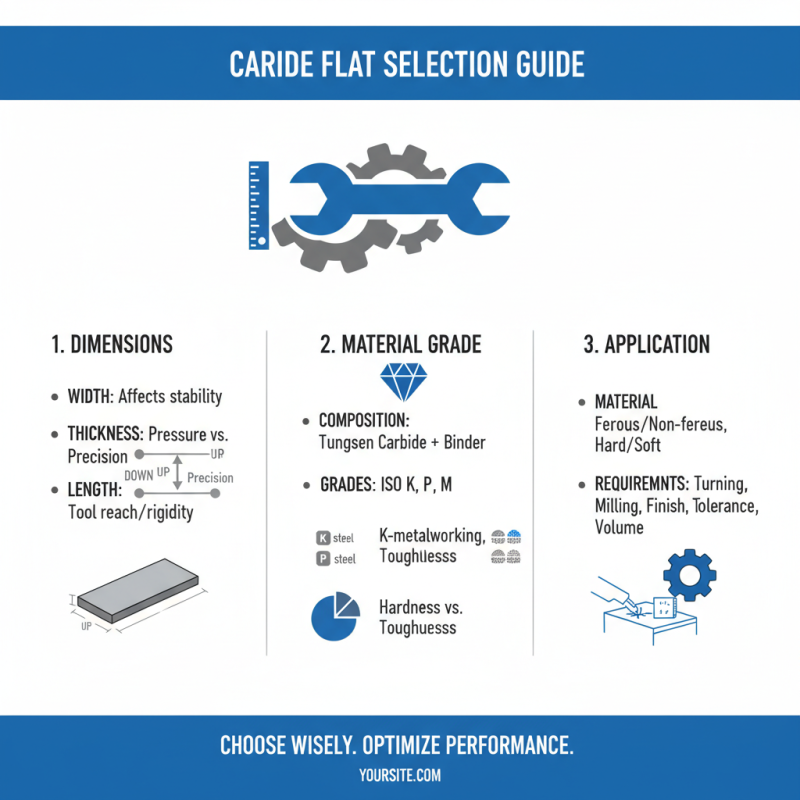

Types of Carbide Flats: Choosing the Right Material Composition

Carbide flats come in various material compositions, each tailored for specific machining applications. Choosing the correct type can significantly impact efficiency and quality. Cobalt content plays a crucial role here. Higher cobalt levels often enhance toughness but may compromise wear resistance. Knowing whether to prioritize durability or cutting efficiency is essential.

Another vital consideration is the carbide grade. For instance, finer grades can offer better surface finishes, while coarser grades are perfect for aggressive cutting. Understanding your project's requirements can guide your selection process. The balance between cost and performance also requires reflection. Cheaper options may lead to faster wear, resulting in more rework.

Sometimes, trial and error can provide valuable insights. Using new flat types on different materials may reveal unexpected results. Not every choice will work flawlessly from the start. Adapting based on previous experiences can refine your approach. The right carbide flat should align with both performance needs and budget constraints, ensuring a smarter investment in your machining efforts.

How to Choose the Right Carbide Flat for Your Machining Needs?

| Type of Carbide Flat |

Material Composition |

Applications |

Hardness (HRA) |

Recommended Use |

| Cemented Carbide |

WC-Co |

Milling tools, cutting inserts |

88-92 |

High wear resistance |

| Ceramic Matrix Composite |

Alumina, Zirconia |

Precision ceramics, high-speed machining |

85-90 |

For brittle materials |

| Cobalt-based Carbide |

WC-Co |

Heavy-duty machining |

90-93 |

High toughness |

| Micro-grain Carbide |

Fine grain size |

Detail work, fine cutting |

87-91 |

Excellent finish |

| High-speed Steel (HSS) |

HSS blends |

Drilling, lateral cutting |

62-68 |

Economical cutting |

Evaluating Dimensions and Specifications for Optimal Performance

Choosing the right carbide flat for machining can be challenging. Each application has unique requirements. Start by considering dimensions like width, thickness, and length. These dimensions directly affect the tool's performance and durability. For instance, a thicker carbide flat can withstand higher cutting pressures. However, it may reduce the precision of your cuts.

Don’t forget to evaluate the specific geometry. Different shapes offer varying cutting properties. Some may excel in shearing, while others are better for finishing cuts. These subtle differences can significantly impact your machining outcomes.

It's also key to acknowledge how material compatibility plays a role. The type of material being machined influences the selection of your carbide flat. Incorrect choices may lead to premature wear or ineffective cutting. Ask yourself: is the chosen carbide flat suitable for the intended material? Reflecting on these factors will help ensure optimal performance in your projects.

Maintaining Carbide Flats for Longevity and Efficiency in Machining

Maintaining carbide flats is crucial for effective machining. These tools endure intense pressure and abrasion. Regular inspection helps identify wear and damage early. Small nicks can lead to bigger issues. A chipped flat might seem minor, but it can impact precision. If ignored, it may cause more costly repairs.

Cleaning is also essential. A build-up of material can affect performance. Use a soft brush to clear debris. Avoid harsh chemicals that can wear down the surface. Regular lubrication keeps the carbide flat operating smoothly. However, don’t overdo it; excess lubricant attracts dirt.

Storage matters too. Keeping carbide flats in a dry, organized place prevents rust and damage. Using protective sheaths can minimize impacts. Consider the environment where they are used. High humidity can accelerate wear. Regularly review your maintenance routine. It’s easy to overlook small details, yet they have a big impact on longevity.

Carbide Flat Tool Selection and Maintenance Overview

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us