How to Choose the Best Solid Carbide Disc Plate for Your Machining Needs

When it comes to machining, selecting the right tools is paramount for achieving precision and efficiency. The choice of a Solid Carbide Disc Plate can significantly impact the outcome of your projects. Industry expert Dr. Emily Carter, a leading authority in cutting tool technology, emphasizes this point by saying, "The right Solid Carbide Disc Plate not only enhances performance but also extends tool life, making it a crucial component in any machining operation."

Understanding the various factors that influence the selection of a Solid Carbide Disc Plate can help machinists make informed decisions that align with their specific needs. From considerations such as material thickness and hardness to the desired finish and tolerances, each facet plays a role in ensuring optimal results. A well-chosen disc plate not only improves machining efficiency but also minimizes production costs in the long run.

In this exploration of how to choose the best Solid Carbide Disc Plate for your machining needs, we will delve into key attributes, industry best practices, and expert insights that will empower machinists to enhance their operations and achieve superior outcomes.

Factors to Consider When Selecting Solid Carbide Disc Plates

When selecting solid carbide disc plates for machining, several critical factors must be considered to ensure optimal performance and longevity. Firstly, the specific application of the disc plate plays a vital role in your choice. For instance, different materials and thicknesses may be required depending on whether you are working with metals, plastics, or composites. Assessing the abrasive nature of the materials being machined will also influence the decision, as more abrasive materials may necessitate a more robust disc plate.

Another key consideration is the geometry of the disc plate. The diameter and thickness are crucial in determining the cutting speed and feed rates suitable for your machining tasks. A thicker disc may offer enhanced stability during operation, while a larger diameter can increase the surface area for cutting, thus improving efficiency. Additionally, understanding the grain size can influence the finish quality of the machined surface and the plate’s overall performance. Ultimately, taking the time to analyze these factors will guide you to select the most appropriate solid carbide disc plate for your unique machining needs.

Comparison of Different Solid Carbide Disc Plates by Application

Understanding the Material Properties of Solid Carbide

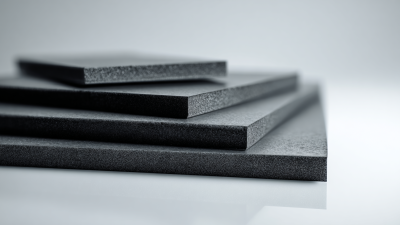

Solid carbide, known for its impressive hardness and wear resistance, is a preferred material in the manufacturing of machining tools such as disc plates. The material's toughness is a key factor, allowing it to withstand high cutting speeds and temperatures. According to a report from a leading materials science institution, solid carbide has a hardness rating of around 90 HRA, significantly contributing to its exceptional performance in demanding machining environments. This hardness enables tools crafted from solid carbide to maintain their cutting edges for longer periods, ultimately reducing tool changeover time and enhancing productivity.

In addition to hardness, the thermal conductivity of solid carbide plays a crucial role in its application. The material typically has a thermal conductivity of approximately 80 W/mK, which helps dissipate heat generated during machining processes. This capability is essential for maintaining optimal cutting conditions and minimizing thermal damage to both the tool and the workpiece. Furthermore, the corrosion resistance of solid carbide is noteworthy; it can withstand various chemicals and high-stress environments, making it suitable for a wide range of machining operations. Understanding these material properties is fundamental for selecting the best solid carbide disc plate that aligns with specific machining requirements, ensuring efficiency and longevity in tool performance.

Different Applications of Solid Carbide Disc Plates in Machining

Solid carbide disc plates are increasingly prominent in various machining applications due to their

exceptional hardness and wear resistance.

In industries such as aerospace,

automotive, and manufacturing,

these plates serve critical roles in cutting, shaping, and finishing a wide range of materials.

Their application spans from precision grinding tools to inserts for milling and turning operations,

which require high accuracy and durability. According to a report by a leading industry analysis firm,

the global market for solid carbide tools is projected to reach $3.5 billion by 2025,

underscoring the growing demand for such machining solutions.

In high-temperature and high-speed operations, solid carbide disc plates outperform alternatives made from other materials.

For instance, in metalworking, they are pivotal in the machining of hard metals like titanium

and Inconel, which are commonly used in aviation components due to their strength-to-weight ratios.

The American Machinist Association indicates that factories employing solid carbide tools can achieve a

20% increase in productivity, primarily due to reduced tool wear and longer operational lifespans.

Moreover, their efficiency not only reduces downtime but also lowers the total cost of ownership in machining processes, making them

a preferred choice among manufacturers prioritizing performance and reliability.

Comparing Solid Carbide Disc Plates to Other Materials

When selecting a solid carbide disc plate for machining, it's essential to understand how it compares to other materials commonly used in the industry. Solid carbide is renowned for its hardness, strength, and wear resistance, making it a preferred choice for high-precision applications. Unlike high-speed steel or cobalt-based alloys, solid carbide tools can maintain their sharpness longer, resulting in reduced downtime for tool changes. This durability makes solid carbide particularly advantageous for machining tough materials like stainless steel and titanium.

In contrast, while high-speed steel tools are easier to sharpen and can withstand a wider range of operating conditions, they typically lack the cutting efficiency and longevity of solid carbide. Other materials, such as ceramic or carbide-tipped tools, may offer benefits in specific scenarios but often fall short in terms of versatility and stability at high speeds. Therefore, understanding the particular benefits of solid carbide disc plates in comparison to alternative materials helps machinists make informed decisions, optimizing performance and productivity in their machining processes.

Tips for Maintaining and Extending the Life of Carbide Disc Plates

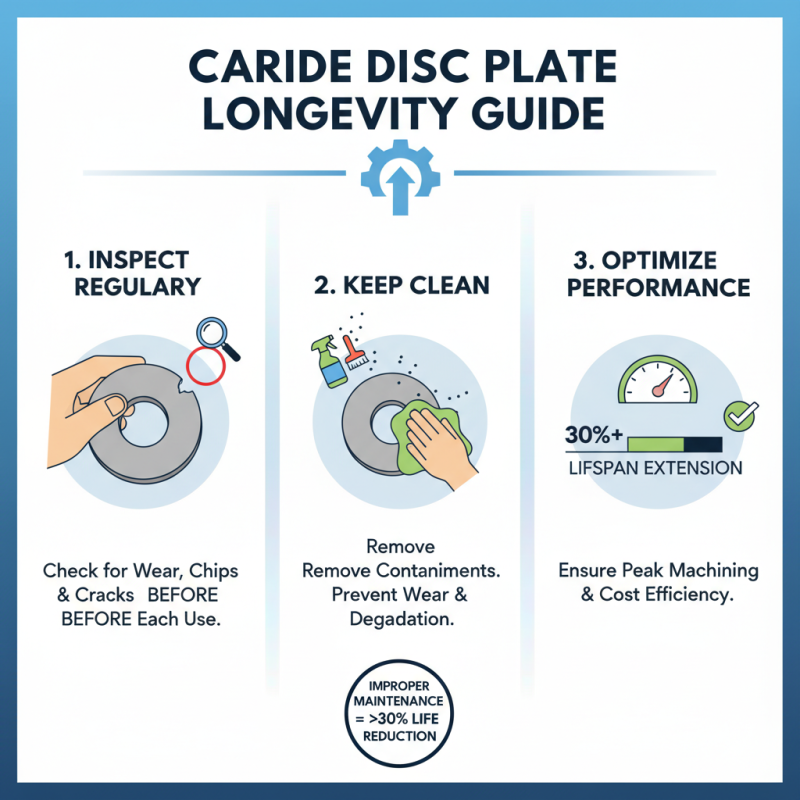

Maintaining and extending the life of solid carbide disc plates is crucial for ensuring optimal machining performance and cost efficiency. Research indicates that improper maintenance can lead to a reduction in the lifespan of carbide tools by over 30%, significantly impacting productivity. Regular inspections are essential; users should check for wear, chips, and cracks before each use. Keeping the plates clean and free from contaminants also helps prevent functionality issues and degradation of performance, as debris can cause unnecessary wear on both the disc and the machining equipment.

Another effective strategy for prolonging the life of carbide disc plates is proper storage and handling. Reports suggest that carbide tools should be stored in a controlled environment where humidity levels are maintained between 30-60%. Moreover, using protective covers can prevent accidental damage and oxidation. Implementing a rotation policy for your tools can also help distribute wear evenly and ensure that all tools are used efficiently, maximizing their operational lifetime. Following these maintenance tips can enhance performance, reduce downtime, and ultimately lower tool replacement costs, providing a significant return on investment for machining operations.

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us