How to Choose Round Carbide Rods for Your Projects?

When selecting Round Carbide Rods for your projects, it can be daunting. The right choice impacts durability and performance. "Quality is paramount when choosing carbide rods," says Dr. James Monroe, an expert in material engineering. His insights reflect the importance of understanding the properties of these rods.

Round Carbide Rods serve various applications, from tooling to manufacturing. They are known for their hardness and resistance to wear. However, selecting the wrong size or grade may lead to inefficiencies. It’s crucial to consider your project needs carefully. Assessing factors like diameter, length, and alloy composition can make a significant difference.

While the potential is high, so is the risk of error. Many overlook the benefits of consulting with experts. In some cases, users rush their decisions, leading to costly mistakes. Taking the time to research and ask questions can enhance outcomes. The selection process should be thoughtful, ensuring the chosen Round Carbide Rods align perfectly with your project goals.

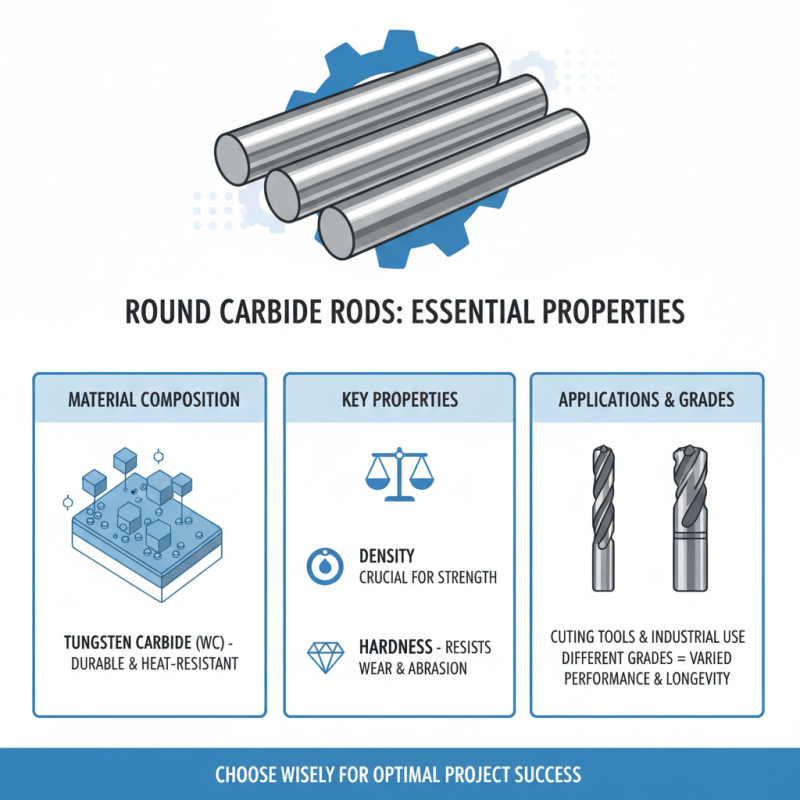

Understanding the Basics of Round Carbide Rods for Project Use

When selecting round carbide rods for your projects, it’s essential to understand their properties. Carbide rods are made from tungsten carbide, a durable material that withstands wear and heat. These rods are often used in cutting tools and industrial applications. Knowing their density and hardness is crucial for making an informed choice. Different grades of carbide serve various purposes, affecting performance and longevity.

Tips: Consider your project’s demands. Is precision important? Choose a rod with tighter tolerances. For heavy-duty tasks, select rods with higher impact resistance.

Knowing the right size is also vital. Round carbide rods come in various diameters and lengths. Measure your needs carefully. A mismatch might lead to inefficiencies or wasted material.

Remember, each application has its quirks. Some rods may chip or break under stress. Always factor in your specific working environment. This understanding can prevent costly mistakes. Make sure to contemplate these elements when choosing round carbide rods.

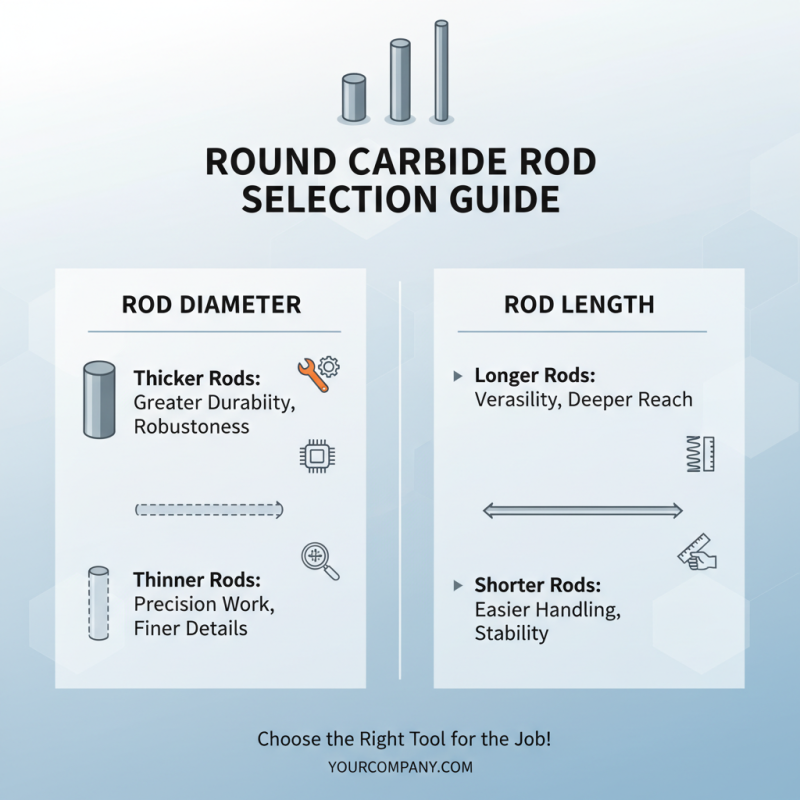

Key Factors to Consider When Selecting Round Carbide Rods

When selecting round carbide rods, several key factors must be taken into account. The diameter of the rod is critical. Thicker rods can provide more durability, while thinner options may be better for precision work. Consider the length as well. Longer rods can be more versatile, but they may also be harder to handle effectively.

Another important aspect is the grade of carbide. Different grades offer various hardness levels and resistance to wear. Higher grade options typically last longer but can increase costs. Don't forget to evaluate the surface finish. A smoother finish can minimize friction, enhancing performance in precision applications.

Sometimes, it’s helpful to think about your specific project needs. Reflect on the conditions where the rods will be used. Harsh environments may require superior strength. Consider how often you'll need replacements too. Poor choices can lead to increased costs and wasted time. Keep these elements in mind to achieve the best outcomes for your machining tasks.

Comparing Different Types of Round Carbide Rods Available

When selecting round carbide rods, it's essential to explore the various types available. These rods come in different grades and coatings, affecting their performance in various applications. Some are uncoated, providing basic hardness but limited wear resistance. Others come with specialized coatings, enhancing their durability and cutting capabilities. Each option suits different project requirements.

Uncoated rods may suffice for simple machining tasks. However, if you plan to tackle more demanding projects, consider coated options. Coatings like TiN (Titanium Nitride) improve surface hardness and longevity. The choice of diameter and length also matters. Larger diameters provide more stability, while shorter rods can enable precise cuts.

Keep in mind that the quality of carbide can vary significantly. Not all rods offer the same performance or lifespan. Testing a few types can help determine the right fit for specific tasks. It's a process that often requires trial and error. A perfect fit rarely exists on the first attempt, and reassessing choices is part of improving results.

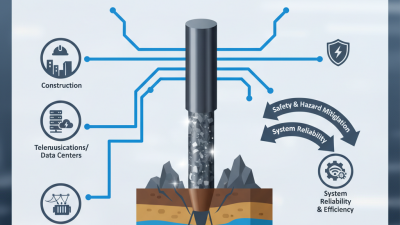

Applications of Round Carbide Rods in Various Industries

Round carbide rods play a crucial role in multiple industries. Their high hardness and wear resistance make them suitable for machining tools. In the automotive sector, these rods are used for manufacturing precision components. They excel in producing durable cutting tools that withstand high temperatures.

In the aerospace industry, round carbide rods contribute to parts that require extreme durability. They are commonly found in turbine blades and compressor components. Their ability to resist wear translates into longer service life. This is essential for safety and efficiency in flight operations.

Manufacturers often overlook the importance of proper specifications. Not all applications require the same size or grade. Choosing the correct type can be challenging. Considerations like geometry and coating are sometimes neglected. Spending time upfront can save expenses later on. Quality and performance result from thoughtful choices.

Applications of Round Carbide Rods in Various Industries

Tips for Ensuring Optimal Performance of Round Carbide Rods

Choosing the right round carbide rods can significantly influence your project's outcome. To ensure optimal performance, you need to consider a few key factors. First, think about the diameter. A larger diameter often gives better strength. However, smaller rods can provide precision in tight spaces. Evaluate your specific needs carefully.

Material quality is another vital aspect. Higher grade carbide can withstand more significant wear and tear. But does it always mean better? Sometimes, cheaper options work fine for less demanding tasks. Balance cost and performance based on your project requirements.

Pay attention to the rod's surface finish. A smoother finish reduces friction, allowing for better performance. Yet, achieving that perfect finish might not always be feasible. Sometimes imperfections can impact your results. Remember, it's about finding the right fit for your unique situation. Don't hesitate to try different options. Reflection on your choices can lead to improved project outcomes.

How to Choose Round Carbide Rods for Your Projects?

| Parameter |

Description |

Importance |

| Diameter |

The thickness of the rod, which affects strength and versatility. |

High |

| Length |

The length of the rod can impact the application and tool life. |

Medium |

| Grade |

Refers to the quality and hardness of the carbide material. |

High |

| Coating |

Additional coatings can improve resistance and performance. |

Medium |

| Application Type |

Specific applications like drilling, milling, or grinding require different rods. |

High |

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us