2026 How to Choose the Best Solid Carbide Disc Plate?

The quest for the perfect Solid Carbide Disc Plate can be daunting. Industry expert Dr. John Miller emphasizes, “Choosing the right disc plate is critical for performance.” His insight highlights the importance of making informed decisions in this niche market.

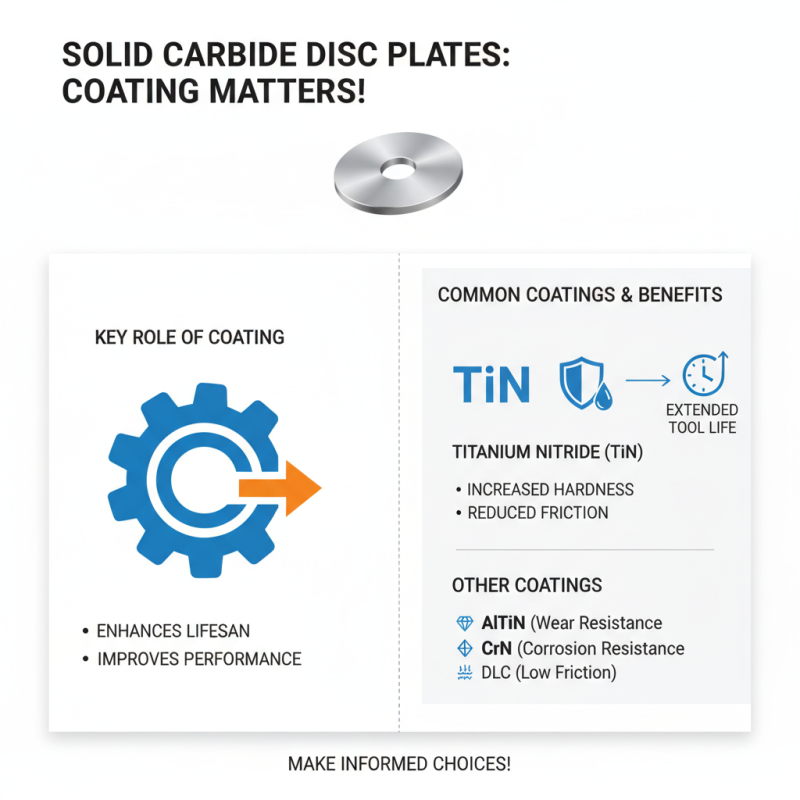

When selecting a Solid Carbide Disc Plate, one must consider several factors. Size, thickness, and coating are essential. Each aspect can impact durability and efficiency. The wrong choice may lead to increased wear or subpar results in manufacturing processes.

Many users overlook these details. They often rush to buy based on price rather than quality. This can result in frustration and wasted resources. A thoughtful approach is key. Investing time in understanding your needs will pay off in the long run.

Understanding Solid Carbide Disc Plates: Specifications and Applications

When it comes to solid carbide disc plates, understanding their specifications is crucial. These plates are known for their exceptional hardness and wear resistance. They are typically used in various applications including industrial machining and cutting tools. The thickness, diameter, and cutting edge geometry significantly impact their performance. Manufacturers often describe these specifications, but the key is to match them to your specific needs.

Applications of solid carbide disc plates are vast. They are common in metalworking industries, particularly for precision cuts. Their durability allows for extended use, reducing the frequency of replacements. However, selecting the wrong plate may lead to inefficient operations. For example, using a disc plate that is too thick could result in an undesirable finish. Manufacturers sometimes claim their discs are all-purpose, but that isn't always the case. Assessing the exact requirements can save time and resources.

Investing in solid carbide disc plates requires careful consideration. Not every plate fits every task. Pay attention to the specifics, such as coating and design. It's easy to overlook these details, yet they can significantly impact machining outcomes. Thus, while the options can be overwhelming, thoughtful selection can lead to better overall performance.

2026 How to Choose the Best Solid Carbide Disc Plate? - Understanding Solid Carbide Disc Plates: Specifications and Applications

| Diameter (mm) |

Thickness (mm) |

Grade |

Application |

Coating Type |

| 100 |

3 |

K10 |

Milling |

TiN |

| 150 |

4 |

K20 |

Cutting |

ZrN |

| 200 |

5 |

K30 |

Grinding |

AlTiN |

| 250 |

6 |

K40 |

Drilling |

Diamond |

| 300 |

8 |

K50 |

Finishing |

TiAlN |

Key Factors in Choosing Solid Carbide Disc Plates for Precision Cutting

Choosing the right solid carbide disc plate is crucial for precision cutting. Several key factors play a significant role in this process. The material composition of the disc affects durability and cutting efficiency. High-quality carbide blends can enhance performance, yet they may also come at a higher cost. Balancing cost and quality is a challenge many face. It's essential to consider whether the extra investment will yield noticeable results.

Another important factor is the disc's geometry. Different designs affect how the plate interacts with various materials. For instance, sharper edges can lead to cleaner cuts, but they may wear out faster. Some users overlook wear resistance, leading to more frequent replacements. This can disrupt workflow and increase expenses.

Finally, the intended application should guide your choice. Are you cutting hard metals or softer materials? Each application requires different specifications. Some may find that a disc plate suitable for one task doesn’t perform well for another. Thus, testing different options might be necessary. This process can be time-consuming, but it's essential to achieve the desired cutting precision.

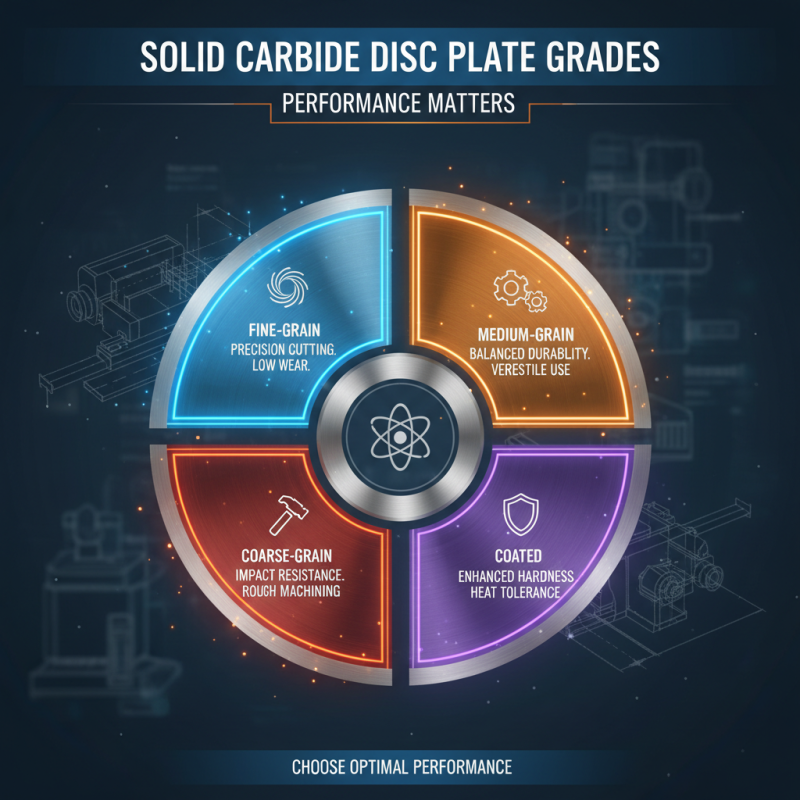

Comparative Analysis of Solid Carbide Disc Plate Grades and Their Performance

Choosing the best solid carbide disc plate requires a thorough understanding of different grades and their performance. Solid carbide materials are known for their durability and exceptional hardness. However, not all grades perform equally well in various applications. Each grade has unique properties that affect cutting efficiency, wear resistance, and heat tolerance.

One must consider the intended use of the disc plate. For example, high-speed machining may need a grade with superior thermal stability. On the other hand, softer materials might require a different approach, favoring grades with good wear resistance. Testing various grades under real-world conditions is essential for informed decision-making.

**Tip:** Conduct experiments with multiple grades to see which performs best in your specific application. This can save time and money in the long run. Always check if there's room for improvement in your choice.

Evaluating the performance of solid carbide disc plates goes beyond just material selection. Factors like coating, geometry, and support systems play a crucial role too. Reflecting on past applications is beneficial. Were there issues with wear or heat? Assessing these challenges can guide you to a better choice.

**Tip:** Keep a detailed log of performance metrics with each grade. This will help track what works and what doesn’t over time.

Cost Analysis: Budgeting for High-Quality Solid Carbide Disc Plates in 2026

In 2026, understanding the cost implications of solid carbide disc plates is crucial. High-quality options can range from $50 to $200 each, depending on size and specification. A recent industry report indicates significant price fluctuations due to raw material costs and production processes. For manufacturers, budgeting wisely can prevent unforeseen expenses.

When evaluating quality versus cost, consider the lifecycle of the product. Investing in durable plates reduces replacement frequency. Reports suggest that using high-quality carbide can increase tool life by up to 30%. This means fewer replacements and lower long-term costs. However, companies must weigh these benefits against initial investment.

Cost analysis also involves maintenance. Quality plates require less frequent sharpening, leading to operational savings. Yet, firms often overlook these long-term advantages. An upfront low-cost option may seem appealing but could lead to higher overall expenses. In the end, a careful approach to budgeting will yield the best return on investment in the solid carbide disc plate market.

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us