How to Choose the Right Circular Blades for Your Cutting Needs

Choosing the right circular blades for your cutting needs is a critical decision that can significantly impact efficiency and productivity across various industries. According to a report by the Global Cutting Tools Market, the demand for high-quality cutting tools, including circular blades, is projected to grow at a CAGR of 5.4% through 2025. This increase is driven by the expanding manufacturing and construction sectors, which rely on precision cutting for everything from metal fabrication to woodworking.

In light of these trends, understanding the characteristics and applications of different circular blades becomes essential. Factors such as blade material, diameter, tooth configuration, and intended use can influence not only the quality of the cut but also the longevity of the blade itself. The American National Standards Institute (ANSI) has established criteria to guide users in selecting the appropriate cutting tools, underscoring the importance of informed choices in optimizing performance and minimizing waste.

Ultimately, selecting the right circular blades tailored to specific cutting requirements is paramount. Proper selection not only enhances operational efficiency but also contributes to cost-efficiency and safety in the workplace. As industries evolve, staying abreast of the latest advancements and best practices in circular blade technology is essential for maintaining a competitive edge.

Understanding Different Types of Circular Blades for Various Materials

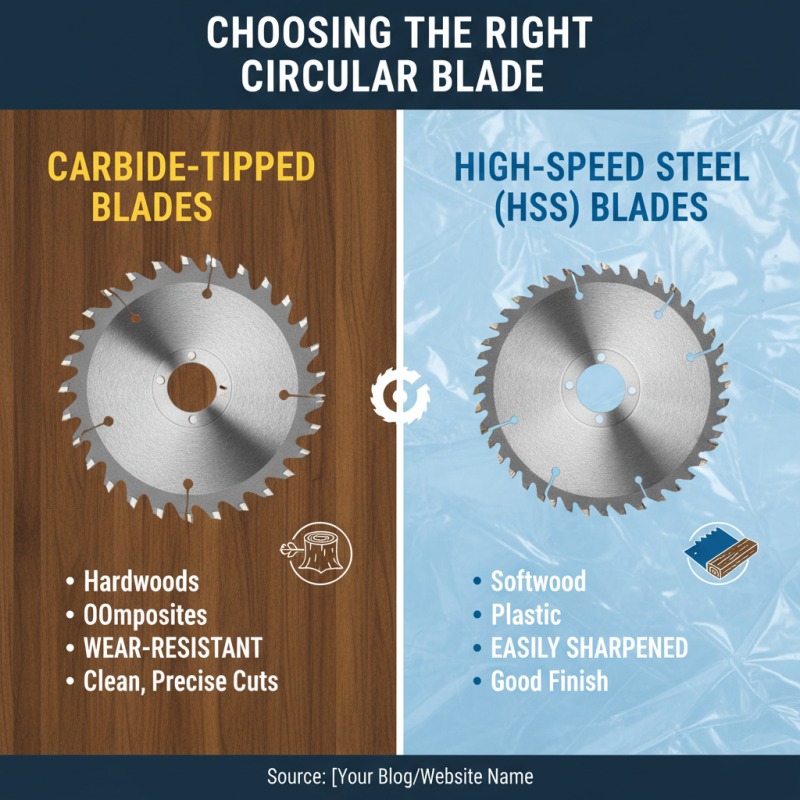

When choosing the right circular blades for your cutting needs, it's essential to understand the various types available, each designed for specific materials. For example, carbide-tipped blades are ideal for cutting hardwoods and composite materials due to their durability and resistance to wear. Their sharp edges allow for clean cuts, making them a favorite among woodworkers seeking precision. On the other hand, high-speed steel (HSS) blades are often recommended for softer materials such as plastic and softwood because they can be sharpened easily and provide a good finish.

Another important category includes specialty blades, designed for unique applications like metal cutting or masonry. Abrasive blades can effectively slice through hard materials like metals and concrete, while diamond blades offer precision for cutting tiles and stone. Each type of blade not only influences the cutting speed and quality but also ensures the safety of the operation. By assessing the specific material and the desired finish, users can select the right circular blade to enhance their cutting performance effectively and efficiently.

Key Factors to Consider When Choosing Circular Blades

When selecting circular blades, there are several key factors to consider to ensure optimal performance for your specific cutting tasks. First, it is essential to assess the material you will be cutting. Different materials, such as wood, metal, or plastic, require blades designed with specific teeth configurations and materials. For instance, if you are working with tougher materials like metal, a blade with carbide tips or high-speed steel is advisable. In contrast, softer materials may only require a simple high-carbon steel blade.

Another important aspect is the blade diameter and thickness, which directly affect the cutting capacity and precision. Larger diameter blades can make deeper cuts and are better suited for thicker materials, while smaller blades excel in precision operations and tighter spaces. Additionally, considering the tooth count is vital; blades with more teeth can produce a smoother finish and are ideal for delicate work, whereas those with fewer teeth are more efficient for faster cuts. By keeping these factors in mind, you can select the right circular blade that meets your cutting needs effectively.

How to Choose the Right Circular Blades for Your Cutting Needs - Key Factors to Consider When Choosing Circular Blades

| Blade Type |

Material |

Diameter (mm) |

Teeth Count |

Cutting Application |

Recommended RPM |

| TCT Blade |

Tungsten Carbide |

250 |

24 |

Wood, MDF |

5000-7000 |

| Carbide Blade |

Carbide-tipped |

300 |

36 |

Plywood, Laminates |

4000-6000 |

| Diamond Blade |

Diamond Coated |

230 |

10 |

Ceramic, Stone |

3000-5000 |

| HSS Blade |

High-Speed Steel |

200 |

40 |

Metal, Plastic |

6000-8000 |

Comparing Blade Sizes and Thickness for Optimal Performance

When selecting circular blades, understanding the relationship between blade size and thickness is crucial for achieving optimal cutting performance. Blade size typically refers to the diameter, which significantly influences the cutting depth and the type of material being processed. Larger blades are often suited for heavy-duty tasks and can handle thicker materials, while smaller blades excel in precision cuts and are ideal for intricate work. Therefore, consider the projects you will undertake and choose a blade size that complements the required application.

On the other hand, blade thickness is equally important, as it affects the stability and durability of the cut. Thicker blades tend to be more robust and can withstand greater stress, making them suitable for tougher materials. However, this added thickness often comes with reduced maneuverability and increased resistance. Conversely, thinner blades can provide cleaner cuts and are more adept at intricate tasks but may require more frequent replacements due to their susceptibility to damage. Balancing size and thickness based on your specific cutting needs will ultimately enhance performance and efficiency in your projects.

Evaluating Blade Tooth Design for Specific Cutting Applications

When selecting circular blades for various cutting applications, evaluating the blade tooth design is crucial to achieving optimal performance and efficiency. Different tooth designs serve distinct purposes; for example, blades with fewer, larger teeth are ideal for making quick cuts through thicker materials, like wood, while blades with an increased number of finer teeth are better suited for smoother finishes on thinner materials, such as plastic or metal. According to the Industrial Cutting Tools Association, the right tooth configuration can enhance cutting speed by up to 40% and improve overall lifespan by reducing wear and tear on the blade.

Furthermore, understanding the material properties of the item being cut can significantly influence the choice of blade tooth design. For harder materials, like stainless steel or composites, a blade with carbide-tipped teeth can provide the necessary durability and cutting precision. On the other hand, softer materials benefit from blades with high-speed steel teeth, which excel at maintaining sharpness without excessive heat buildup. Research from the American Society of Manufacturing Engineers indicates that the correct tooth design can reduce production time by as much as 25% and lower the costs associated with blade replacements, making it an essential factor for manufacturers looking to enhance their operational efficiencies.

Maintenance Tips for Enhancing the Longevity of Circular Blades

Maintaining the longevity of circular blades is crucial for optimal performance and cost-efficiency in cutting applications. According to a recent report by the Cutting Tool Institute, regularly maintained blades can last up to 50% longer than those that are neglected. This not only reduces replacement costs but also minimizes downtime in production settings, which is essential for businesses aiming to maximize productivity. Key maintenance practices include regular inspection for wear and sharpness, ensuring blades are cleaned after use, and correct storage methods to prevent damage.

Sharpening is another pivotal aspect of blade maintenance. A study published in the Journal of Manufacturing Processes indicates that properly sharpened blades can improve cutting precision by 20%, which is particularly crucial in industries like woodworking and metalworking. It's essential to follow manufacturer guidelines on sharpening intervals based on the type of material being cut and the volume of work. Utilizing the appropriate sharpening tools and techniques will further enhance the blade’s lifespan and maintain its cutting efficiency, resulting in better quality outputs and a reduction in production waste.

Choosing the Right Circular Blades - Usage vs. Maintenance

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us