How to Choose the Right Pcb Carbide Rods for Your Applications?

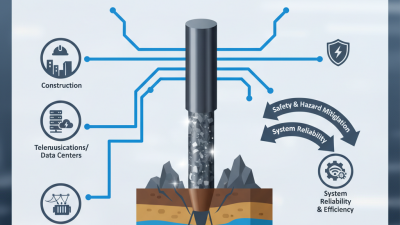

Choosing the right Pcb Carbide Rods is essential for various industries, from aerospace to manufacturing. According to a recent report by the Global Composite Materials Market, the demand for carbide rods is projected to grow by 7.5% annually. This growth highlights the need for precision and durability in applications requiring these materials.

In the context of high-performance tools, understanding the specific properties of Pcb Carbide Rods is crucial. They offer superior wear resistance and hardness. However, selecting the wrong type can lead to inefficiencies and increased production costs. Many users struggle with balancing performance and cost-effectiveness in their choices.

Industry leaders emphasize the importance of matching the right carbide rods to specific applications. There are multiple factors influencing this decision: rod length, diameter, and grade composition. Each aspect can significantly impact performance. In many cases, users overlook these details, leading to potential failures. The choice of the right Pcb Carbide Rods is not just about selection; it’s a vital step toward achieving operational excellence.

Understanding PCB Carbide Rods and Their Applications

PCB carbide rods are known for their toughness and precision. These rods are widely used in various applications, particularly in the tools industry. They are ideal for manufacturing cutting tools, dies, and molds. According to a recent industry report, over 70% of cutting tools utilize carbide materials due to their high wear resistance and durability. This makes them highly sought after in machining processes.

Choosing the right PCB carbide rods involves understanding their unique properties. The composition of carbide affects the performance during machining. Coatings can also play a role in extending tool life. Research shows that carbide tools can last up to five times longer than high-speed steel tools. However, not all carbide rods are created equal. Varied grades exist, and picking the wrong one could lead to suboptimal performance.

Application matters when selecting carbide rods. For example, rods used for high-speed applications must endure heat better than those used in lower-speed settings. Reports indicate that improper selection can lead to premature wear or failure. This stresses the importance of matching the right rod type with specific application needs. Always reflect on your choice to ensure the best results in your projects.

How to Choose the Right PCB Carbide Rods for Your Applications?

| Type of PCB Carbide Rod |

Applications |

Hardness (HRA) |

Density (g/cm³) |

Common Diameter (mm) |

Typical Length (mm) |

| Cemented Carbide |

Cutting Tools, Molds |

89 |

14.5 |

3, 4, 6 |

200, 300 |

| Cubic Boron Nitride (CBN) |

Precision Grinding, Tool Coatings |

70-80 |

3.5 |

4, 6, 10 |

150, 250 |

| Polycrystalline Diamond (PCD) |

High Precision Cutting, Woodworking |

85-90 |

1.6 |

5, 8, 12 |

100, 200 |

| Tungsten Carbide |

Drills, Inserts, Wear Parts |

87 |

15.5 |

6, 8, 10 |

100, 150 |

Key Factors to Consider When Selecting PCB Carbide Rods

When selecting PCB carbide rods, consider several key factors. First, the application requirements must guide your choice. Each application has unique needs. The hardness and wear resistance of the rods are critical. Harder materials perform better in high-wear scenarios.

Next, think about the size and shape of the rods. Custom dimensions may be necessary for specific equipment. Rods should fit perfectly in your machinery. Pay attention to the finish of the rods as well. A smooth surface can reduce friction and improve performance.

Lastly, consider the cost-effectiveness of your choice. Sometimes, the cheapest option isn’t the best. Quality may suffer, affecting your end product. Evaluating these factors can be tricky. Gather feedback and test samples when possible. This ensures you make informed decisions tailored to your needs.

Comparing Different Types of PCB Carbide Rods for Specific Uses

When selecting PCB carbide rods, it's crucial to consider their specific applications. Different types of carbide rods offer unique properties. Some are designed for wear resistance, while others focus on high-temperature stability. For industries like aerospace, choose rods that endure extreme conditions. They need to maintain integrity under stress.

Compare various shapes and sizes as well. Round rods might suit certain cutting applications better than flat ones. Different diameters can affect the rod’s performance. You can experiment with a range of rods to find the right fit. Remember, it's a process of trial and error.

Not all carbide rods are created equal. Some may not perform as expected. Consider the machining techniques you use; they can impact outcomes. Regular testing and feedback help refine your choices. Sometimes, the ideal rod is not what you initially think. Stay open to adjustments.

Comparison of PCB Carbide Rods by Application

Evaluating Quality and Performance Metrics of PCB Carbide Rods

When evaluating quality and performance metrics of PCB carbide rods,

several factors come into play. Hardness

is crucial. High-quality rods typically exhibit a hardness of about 90 HRA.

This translates to superior wear resistance in demanding applications. Rigorous testing

reported that rods with lower hardness levels may degrade quickly, leading to premature failures.

Another critical metric is the flexural strength. Research indicates that

robust carbide rods can achieve strengths exceeding 400 MPa. This strength

ensures durability during mechanical stress. Models that fall below this threshold can lead to

catastrophic breakage under load, which can disrupt production timelines.

Surface finish also matters. A

smoother surface can reduce friction and enhance performance. Studies suggest that a

finish of 0.8µm or better offers significant performance advantages.

However, not all manufacturers achieve this standard. Thus, users must assess surface

quality, as rough finishes can compromise efficiency and lifespan.

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us