The Science Behind Circular Blades: Innovations and Applications in Modern Cutting Technology

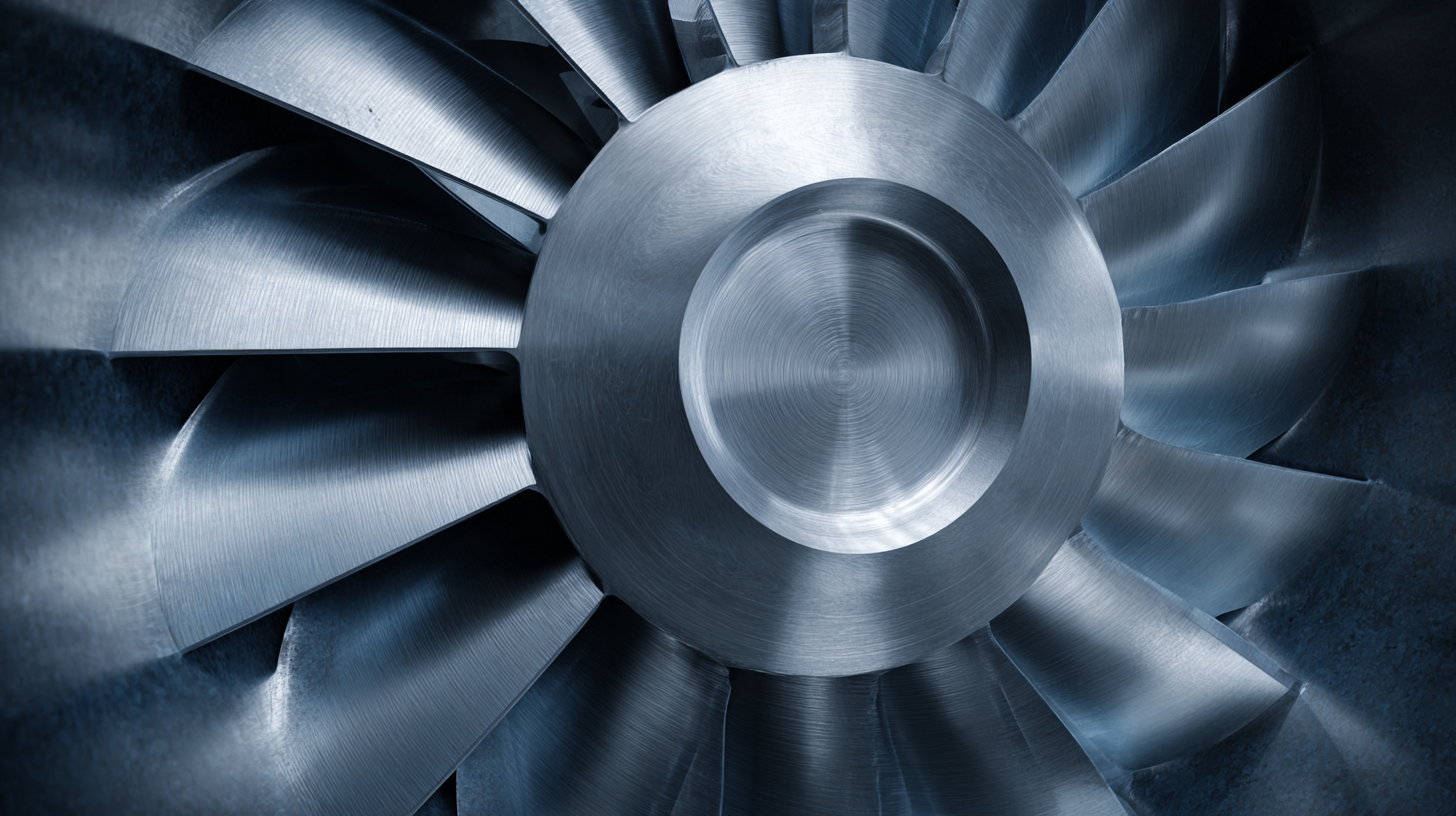

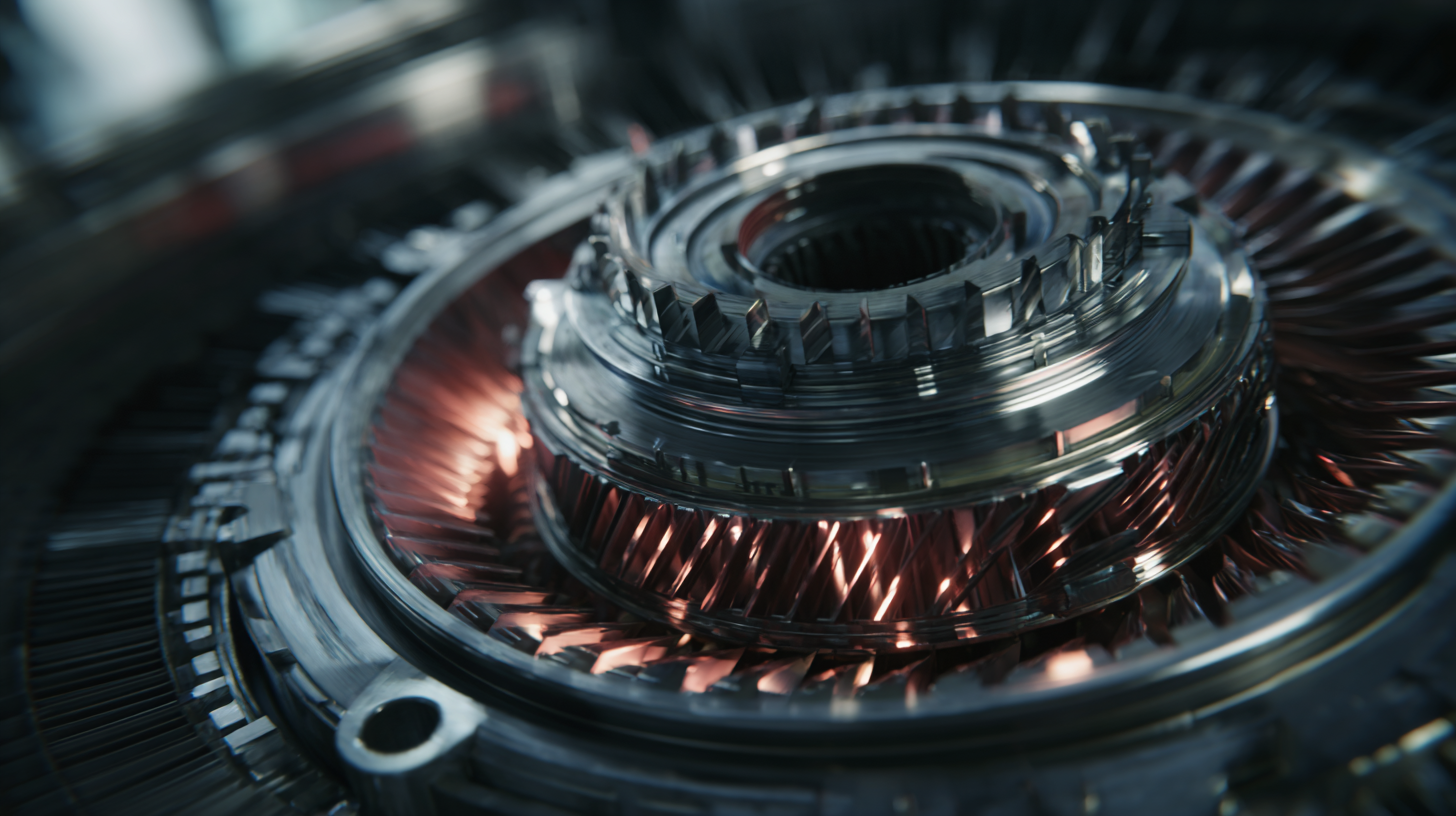

Circular blades have revolutionized cutting technology, playing a pivotal role across various industries, including manufacturing, woodworking, and food processing. According to a report by Markets and Markets, the global circular saw market is projected to reach USD 3.23 billion by 2025, reflecting a Compound Annual Growth Rate (CAGR) of 4.5% from 2020. This surge is attributed to innovations in blade materials and coatings that enhance performance and longevity.

Circular blades have revolutionized cutting technology, playing a pivotal role across various industries, including manufacturing, woodworking, and food processing. According to a report by Markets and Markets, the global circular saw market is projected to reach USD 3.23 billion by 2025, reflecting a Compound Annual Growth Rate (CAGR) of 4.5% from 2020. This surge is attributed to innovations in blade materials and coatings that enhance performance and longevity.

Furthermore, advancements in precision engineering have led to the development of circular blades that not only improve cutting speed and accuracy but also reduce waste and energy consumption. With applications ranging from intricate designs in metal cutting to high-speed slicing in food production, the science behind circular blades is driving efficiency and sustainability in modern operations.

Exploring these innovations will provide insights into how circular blades continue to shape the future of cutting technologies.

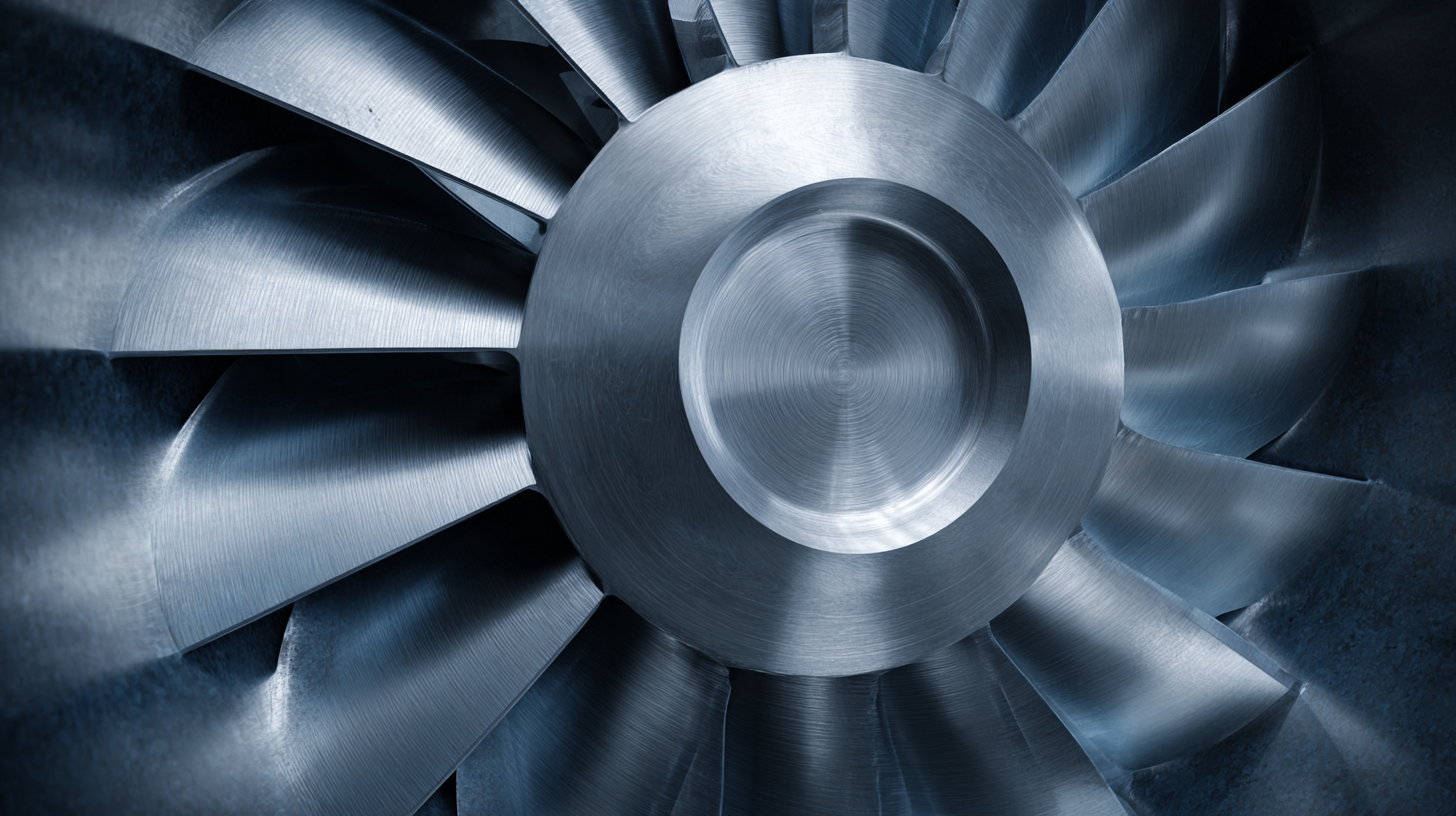

Understanding the Fundamentals of Circular Blade Design and Functionality

Circular blades have become a cornerstone of modern cutting technology, thanks to their unique design and versatility. Understanding the fundamentals of circular blade design involves examining the materials used, the blade geometry, and their interaction with different cutting processes. According to a report by Grand View Research, the global market for circular saw blades is expected to reach USD 1.1 billion by 2027, reflecting a growing demand for precision and efficiency in various industries, including woodworking, metalworking, and construction.

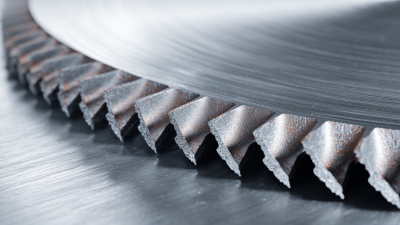

The functionality of circular blades is heavily influenced by their design features, such as tooth shape, spacing, and the type of coating applied. Advanced materials, such as carbide and diamond, enhance durability and cutting performance, enabling blades to operate at higher speeds and with greater efficiency. A study by the Cutting Tool Engineering magazine highlights that blades with optimized tooth geometry can improve cutting speeds by up to 30%, significantly reducing operational costs. This advancement is pivotal for manufacturers striving for precision while minimizing waste in the production process.

Advancements in Materials for Enhanced Cutting Performance

Recent advancements in materials technology have significantly enhanced the performance of circular blades in cutting applications. Innovations such as high-speed steel and advanced carbide composites have led to blades that offer superior wear resistance and increased lifespan. According to a report by MarketsandMarkets, the global market for cutting tools, including circular blades, is projected to reach USD 28.5 billion by 2026, driven largely by these material innovations.

One notable development is the introduction of diamond-coated circular blades, which can outperform traditional materials by providing exceptional sharpness and durability. These blades exhibit a longer operational life by resisting chipping and degradation, making them ideal for precision cutting in industries such as aerospace and automotive. A recent study published in the Journal of Manufacturing Processes highlighted that diamond-coated blades can retain sharpness for up to 5 times longer than conventional steel blades, thereby reducing replacement frequency and overall operational costs for manufacturers.

Applications of Circular Blades in Various Industries

Circular blades have become an essential tool across various industries due to their efficiency and precision in cutting materials. In the aerospace sector, these blades are utilized in the manufacturing of lightweight components, contributing to improved fuel efficiency in aircraft design. Similarly, the automotive industry has integrated advanced circular blade technology for cutting through complex materials, helping to streamline production processes and enhance vehicle performance.

In addition to these applications, the rise of carbon fiber reinforced thermoplastics (CFRTs) has opened new avenues for circular blades, especially in high-performance environments. These materials not only provide strength and durability but also require precise cutting, where advanced circular blades excel. Moreover, the expanding market for wind blade recycling highlights the importance of effective cutting technologies that can process composite materials, ensuring sustainability in wind energy production. This demonstrates the adaptability of circular blades in addressing both manufacturing needs and environmental concerns across diverse industrial sectors.

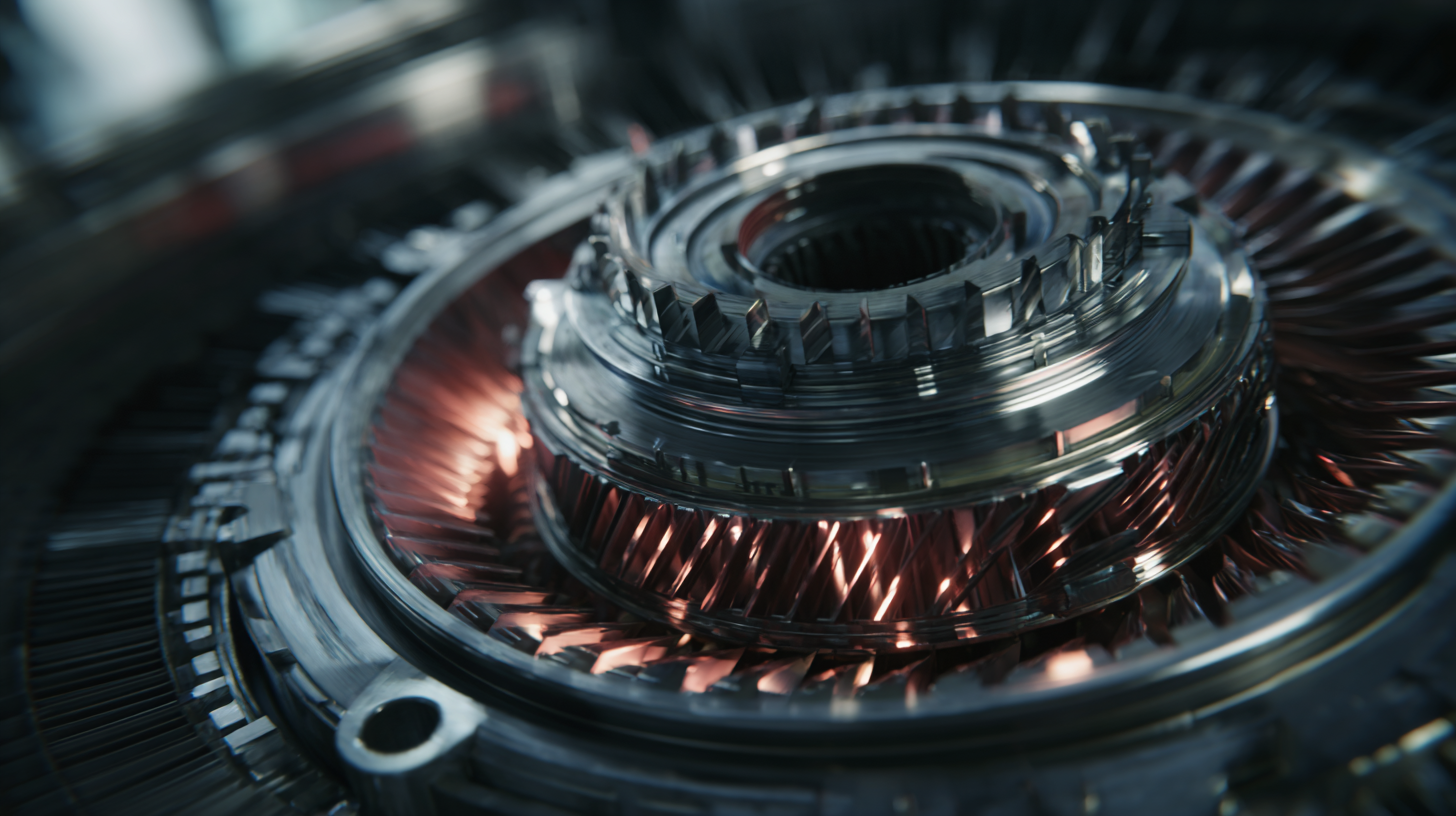

Innovative Technologies Driving the Future of Cutting Tools

Innovative technologies are rapidly transforming the landscape of cutting tools, particularly with the advent of circular blades. Recent data from the Allied Market Research report predicts that the global cutting tools market will reach $29.37 billion by 2026, growing at a compound annual growth rate (CAGR) of 6.3%. This growth is driven by advancements in materials science and manufacturing techniques, allowing for the creation of blades that boast improved performance and durability. The introduction of advanced coatings, such as TiN and TiAlN, has enhanced resistance to wear and thermal shock, prolonging tool life and sustainability.

Furthermore, the integration of smart technology into cutting tools is revolutionizing their applications across various industries. For instance, Industry 4.0 principles are being adopted, enabling circular blades to be embedded with sensors that monitor performance metrics in real-time. According to a report by Grand View Research, the smart cutting tools segment is expected to grow significantly, reflecting a shift towards more precise and efficient machining processes. These innovations not only streamline operations but also minimize waste, aligning with global sustainability efforts and enhancing productivity in demanding environments.

Sustainability and Circular Blades: Environmental Considerations and Solutions

The development of circular blades in modern cutting technology not only enhances efficiency but also addresses pressing environmental concerns. According to a report from the International Cutting Tools Association, approximately 40% of the materials processed in industrial settings are wasted due to inefficient cutting methods. Circular blades, with their design aimed at precision and clean cuts, contribute significantly to reducing this waste. By optimizing material usage, the adoption of these blades can lead to a 15% decrease in disposal costs and a reduction in the consumption of raw materials, which is crucial in promoting sustainability.

Moreover, circular blades are increasingly being produced with eco-friendly materials and coatings, which can minimize their environmental impact. Research by the Green Manufacturing Initiative indicates that blades made from recycled materials can reduce the carbon footprint of the cutting process by up to 30%. Additionally, advancements in manufacturing techniques have led to blades that require less energy during production and exhibit longer lifespans, thereby reducing the frequency of replacements and associated industrial waste. These innovations ensure that the cutting industry not only meets efficiency standards but also actively contributes to a circular economy through sustainable practices.

The Science Behind Circular Blades: Innovations and Applications in Modern Cutting Technology

| Application Area |

Material |

Blade Type |

Environmental Impact |

Innovative Features |

| Woodworking |

Hardwood |

Tungsten Carbide Blades |

Low Waste Production |

Self-Sharpening Technology |

| Metal Fabrication |

Aluminum |

Cobalt Alloy Blades |

Recyclable Materials |

Cooling Coating Technology |

| Textile Cutting |

Natural Fibers |

Ceramic Blades |

Reduced Energy Consumption |

Precision Edge Technology |

| Food Processing |

Meat and Vegetables |

Stainless Steel Blades |

Biodegradable Options |

Antimicrobial Coatings |

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us

Circular blades have revolutionized cutting technology, playing a pivotal role across various industries, including manufacturing, woodworking, and food processing. According to a report by Markets and Markets, the global circular saw market is projected to reach

Circular blades have revolutionized cutting technology, playing a pivotal role across various industries, including manufacturing, woodworking, and food processing. According to a report by Markets and Markets, the global circular saw market is projected to reach