10 Incredible Uses for Tungsten Carbide Round Bars You Never Knew Existed!

Tungsten Carbide Round Bars have emerged as a pivotal component in various industries, owing to their unparalleled hardness and resistance to wear. According to a recent report by Grand View Research, the global market for tungsten carbide is expected to reach USD 35 billion by 2025, driven by the increasing demand for advanced materials in manufacturing and construction. These robust round bars are not just limited to their traditional applications in cutting tools and mining equipment; they also serve innovative purposes across diverse sectors. From enhancing the durability of machinery to being used in high-performance sporting goods, the versatility of Tungsten Carbide Round Bars is astounding.

In this article, we will explore ten incredible uses for Tungsten Carbide Round Bars that you never knew existed, demonstrating their impact across multiple industries and revealing their potential for novel applications.

Innovative Applications of Tungsten Carbide Round Bars in Aerospace Engineering

Tungsten carbide round bars have emerged as a game-changing material in aerospace engineering, primarily due to their unmatched hardness and strength. These attributes make them ideal for manufacturing critical components that must withstand extreme conditions. For instance, tungsten carbide is increasingly used in the production of turbine blades, where resistance to wear and thermal damage is paramount. The density and durability of tungsten carbide allow engineers to create more efficient turbine designs, enhancing fuel efficiency and performance.

Moreover, tungsten carbide round bars are utilized in landing gear components. Their exceptional tensile strength ensures that these parts can endure the stresses and impacts associated with takeoff and landing. Engineers also harness the wear resistance of tungsten carbide in tools used for machining and manufacturing aerospace parts, leading to longer tool life and reduced downtime. As the aerospace industry continues to demand higher performance and safety standards, the innovative applications of tungsten carbide round bars will undoubtedly be pivotal in advancing technology and design.

10 Incredible Uses for Tungsten Carbide Round Bars in Aerospace Engineering

Enhancing Wear Resistance: Tungsten Carbide in Industrial Machinery Components

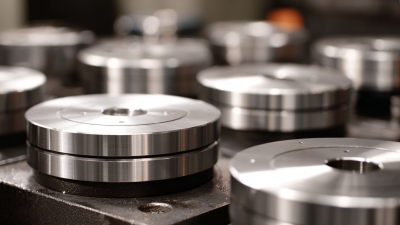

Tungsten carbide round bars are becoming increasingly popular in various industrial applications, primarily due to their exceptional wear resistance properties. This remarkable material is composed of tungsten and carbon, creating a compound that is significantly harder than steel. As such, its use in the manufacturing of industrial machinery components significantly enhances the durability and lifespan of equipment, minimizing the need for frequent replacements and repairs.

In industries where machinery is subjected to high levels of friction and stress, such as construction, mining, and manufacturing, tungsten carbide components can withstand harsh conditions. For instance, tools equipped with tungsten carbide tips are designed to endure extreme abrasion, proving invaluable in processes like drilling and cutting. Furthermore, these round bars can be ingeniously integrated into various machinery parts, such as bearings and bushings, where their wear-resistant nature reduces operational failures and maintenance costs.

Overall, the incorporation of tungsten carbide in industrial machinery not only optimizes performance but also contributes to a more efficient and cost-effective production process.

The Role of Tungsten Carbide Round Bars in Medical Device Manufacturing

Tungsten carbide round bars have emerged as a pivotal component in the medical device manufacturing sector, thanks to their exceptional hardness and wear resistance. These attributes not only enhance the longevity of tools used in medical procedures but also ensure precision in the creation of intricate components. As noted in industry reports, the market for tungsten carbide in medical applications is expected to grow at a compound annual growth rate (CAGR) of over 6% from 2023 to 2030, driven by innovations in surgical instruments and implants that require durable and dependable materials.

Recent advancements in materials science, including the development of multi-criteria decision-making tools like CM3D, have underscored the importance of selecting the right materials for medical devices. Tungsten carbide round bars support the rigorous demands of the healthcare industry, offering not just functionality but also contributing to the sustainability goals by promoting circular economy practices. As manufacturers focus on reducing waste and enhancing efficiency, the integration of tungsten carbide into medical device production stands out, paving the way for enhanced patient outcomes and operational excellence.

Exploring Tungsten Carbide Round Bars in Oil and Gas Exploration Equipment

Tungsten carbide round bars have emerged as a pivotal component in oil and gas exploration equipment, owing to their exceptional hardness and resistance to wear. As industries push for more durable and efficient tools, the demand for tungsten carbide has surged. According to recent market analysis, the global tungsten market was valued at approximately USD 1.39 billion in 2025, with expectations to reach USD 1.51 billion in 2026. The market is projected to grow significantly, potentially hitting USD 3.5 billion by 2035, indicating a robust interest in high-performance materials like tungsten carbide.

In the oil and gas sector, the unique properties of tungsten carbide round bars lend themselves well to various applications, including drill bits, valve components, and downhole tools. Their ability to withstand extreme pressures and temperatures makes them an ideal choice for exploration activities in challenging environments. The trend of adopting advanced materials in drilling equipment not only enhances operational efficiency but also minimizes wear and tear, thus reducing overall maintenance costs. As the industry increasingly focuses on innovation and sustainability, the utilization of tungsten carbide is set to play a crucial role in meeting future demands.

Tungsten Carbide Round Bars: A Game Changer for Custom Tooling Solutions

Tungsten carbide round bars are revolutionizing the custom tooling landscape, striking a perfect balance between durability and versatility. Crafted from one of the hardest known materials, these round bars are ideal for creating precision tools that can withstand rigorous applications. In industries that demand high-performance cutting and machining solutions, tungsten carbide round bars have emerged as game changers, enabling manufacturers to push their operational limits while ensuring superior tool life.

The rise of cermet-tipped blades is indicative of the evolving tooling market, but tungsten carbide remains unmatched in its capacity for heavy-duty performance. Whether shops need to hog out large volumes of material or achieve finer finishing cuts, tungsten carbide round bars can be molded into end mills and other tooling configurations that enhance productivity and reduce downtime. Their resilience to wear and fracture makes them a preferable choice, leading to increased efficiency and cost-effectiveness in manufacturing processes. As businesses seek solutions that provide both strength and precision, tungsten carbide round bars are proving to be indispensable in the quest for advanced custom tooling solutions.

10 Incredible Uses for Tungsten Carbide Round Bars You Never Knew Existed!

| Use Case |

Description |

Industry |

Advantages |

| Machining Tools |

Used for cutting, drilling, and milling operations. |

Manufacturing |

High hardness and resistance to wear. |

| Jewelry Making |

Custom tungsten carbide rings and pendants. |

Retail |

Durability and scratch resistance. |

| Aerospace Components |

Parts for aircraft engines and structural components. |

Aerospace |

High strength-to-weight ratio and durability. |

| Mining Tools |

Drills and bits used in excavation. |

Mining |

Excellent wear resistance for harsh conditions. |

| Cutting Edge Tools |

High-performance cutting tools for precision work. |

Manufacturing |

Long-lasting performance with precise edges. |

| Valve Components |

Critical parts in fluid control systems. |

Oil & Gas |

Resistant to corrosion and high pressures. |

| Wear Parts |

Components designed to withstand wear in machinery. |

Construction |

Extended lifespan and reduced maintenance costs. |

| Knives and Blades |

High-performance blades for cutting applications. |

Culinary |

Sharpness and resist wear from cutting. |

| Electronics |

Components in high-performance devices. |

Technology |

Improved performance and longevity. |

| Sporting Equipment |

Durable components in tools and gear. |

Sports |

Enhanced durability for extreme activities. |

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us