What is a Milling Cutter and How to Choose the Right One?

Milling cutters are essential tools in the machining world. They shape materials with precision. Choosing the right milling cutter can be challenging. This decision affects the quality and efficiency of your work. A suitable cutter can enhance performance and reduce time.

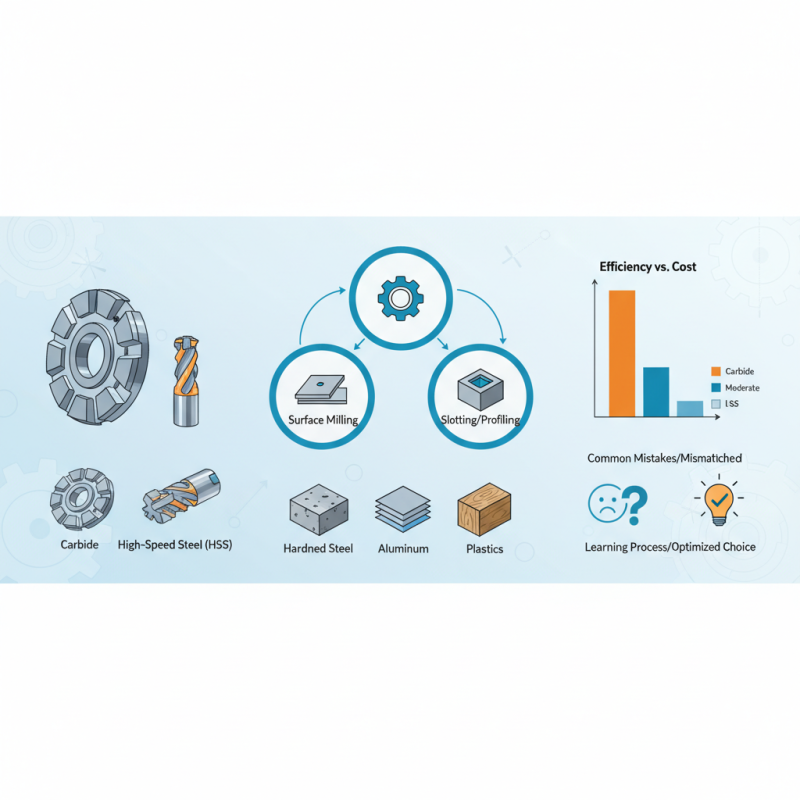

Different types of milling cutters exist. Each serves a specific purpose. A face mill cuts flat surfaces, while an end mill is versatile for various tasks. The material of the cutter also matters. Carbide tools are durable and efficient, but they can be costly. Moreover, some projects may need specialized cutters.

Understanding these aspects is vital. However, mistakes are common when selecting a milling cutter. Sometimes, the chosen cutter does not match the intended material or application. Such oversights can lead to poor results. Reflecting on your choices can improve future projects. It’s a learning process, and each experience adds value.

What is a Milling Cutter?

A milling cutter is a vital tool in machining. It shapes and removes material from workpieces. Commonly used in milling machines, these cutters come in various forms. Each design serves a specific function. Understanding these nuances is essential for effective machining.

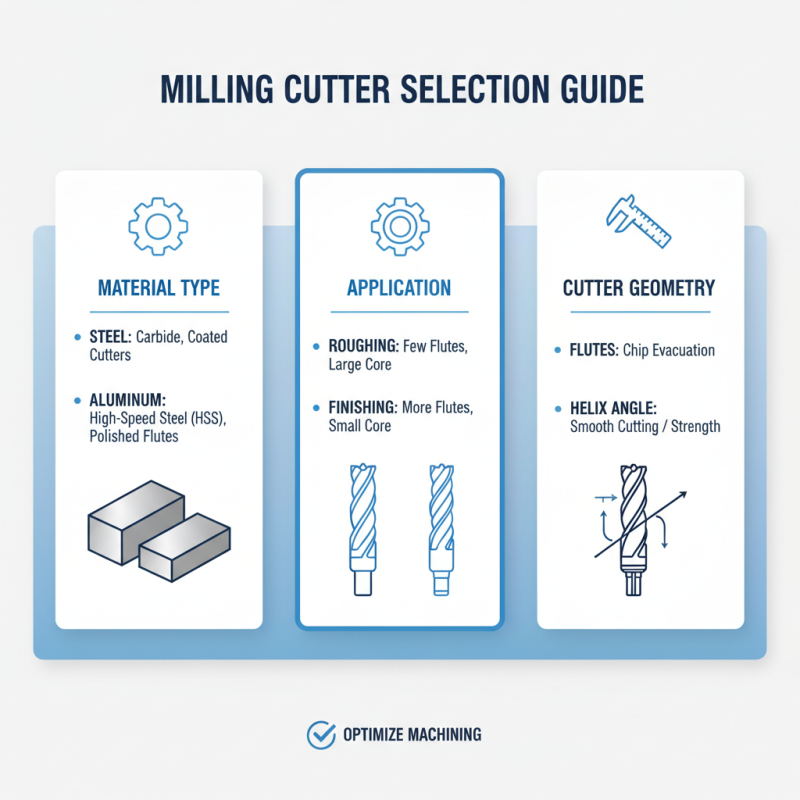

Choosing the right milling cutter requires knowledge. Consider the material being shaped. Harder materials, like steel, need stronger cutters. Softer materials, such as aluminum, can use lighter options. The cutter's geometry, like flutes and teeth, impacts performance. More flutes can allow for smoother finishes but may reduce chip clearance.

Tips: Always match the cutter with the job. This prevents wear and tear. Check compatibility with your milling machine. Improper fit can lead to accidents. Be mindful of tool life, and regularly inspect cutters for wear. Changing worn tools ensures efficiency.

Types of Milling Cutters and Their Applications

Milling cutters are essential tools in machining. They come in various types, each designed for specific applications. The most common types include end mills, face mills, and slab mills. According to recent industry reports, end mills account for 35% of the global milling cutter market. They are perfect for creating complex shapes and slots in materials like aluminum and steel.

Face mills are widely used for facing operations. They provide a large surface area for cutting and can handle heavier cuts. Recent studies show that face mills lead to a significant reduction in machining time. However, they can be more expensive, and selecting the right insert is critical for performance. Slab mills, though less common, are still vital for producing flat surfaces. They operate efficiently at high speeds.

Choosing the right milling cutter requires careful consideration. Factors such as material type, cutter geometry, and surface finish must be evaluated. A mismatch can lead to poor results. In the milling industry, up to 25% of production costs could stem from incorrect tool choice. Hence, it’s crucial to understand the specific needs of your project to improve efficiency and reduce waste.

Factors to Consider When Choosing a Milling Cutter

Choosing the right milling cutter is crucial for machining efficiency. Several factors can influence your decision. First, consider the material you'll be working with. Different materials require different cutter types. For example, steel and aluminum need different cutting edges.

Another key factor is the cutter diameter. Larger diameters can cover more area, but they may not fit in tight spaces. It's important to balance size with maneuverability. The number of teeth on the cutter also matters. More teeth can provide a smoother finish, but they reduce chip removal efficiency.

Lastly, think about the cutter's coating. Coatings can enhance tool life and performance. However, some coatings are not suitable for all materials. Testing various options may lead to a better choice. Sometimes, trial and error reveal what really works for your specific needs. Ensure you have a clear understanding of your projects to make informed decisions.

Common Mistakes to Avoid When Selecting Milling Cutters

Choosing the right milling cutter can be challenging. Many people overlook crucial factors, leading to poor machining results. One common mistake is not considering the material to be cut. Each cutter is designed for specific materials. Using the wrong cutter can damage both the workpiece and the tool.

Another mistake is ignoring the cutter's geometry. A cutter's shape affects its performance. For instance, a tapered cutter may be better for intricate designs. Failing to match the geometry to the job requirements can result in inefficiency and extra costs. Always evaluate the cutter's design before making a purchase.

Tips: Always keep a log of the cutters you use. This approach helps in identifying which tools work best for various materials. Adjust your selection strategy as needed to enhance your results. Experimentation is key. Test different cutters to find the right fit for your unique projects. Don’t hesitate to reflect on previous choices to make better-informed decisions.

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

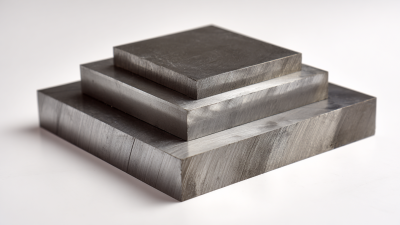

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us