Unlocking the Benefits: What is a Round Carbide Blade and Why Choose It?

The cutting tool industry has evolved significantly, with advancements in

materials and design leading to more efficient,

durable products. Among these innovations, the

Round Carbide Blade

stands out as a preferred choice for professionals seeking precision and longevity in their cutting

applications.

According to a recent report by the Industrial Tool Manufacturer's Association,

blades made from carbide outperform traditional steel options by over

50% in terms of cutting lifespan and durability.

This remarkable performance is attributed to the unique properties of carbide, which boasts a

hardness rating that allows it to maintain sharpness longer while

resisting wear from tough materials. Additionally, a study from the

Cutting Tool Engineering Journal highlights that utilizing

Round Carbide Blades

can enhance cutting speeds by up to

30%, translating into significant productivity

gains. As industries continue to demand efficiency and quality, the

Round Carbide Blade

emerges as a critical tool in meeting these evolving challenges.

According to a recent report by the Industrial Tool Manufacturer's Association,

blades made from carbide outperform traditional steel options by over

50% in terms of cutting lifespan and durability.

This remarkable performance is attributed to the unique properties of carbide, which boasts a

hardness rating that allows it to maintain sharpness longer while

resisting wear from tough materials. Additionally, a study from the

Cutting Tool Engineering Journal highlights that utilizing

Round Carbide Blades

can enhance cutting speeds by up to

30%, translating into significant productivity

gains. As industries continue to demand efficiency and quality, the

Round Carbide Blade

emerges as a critical tool in meeting these evolving challenges.

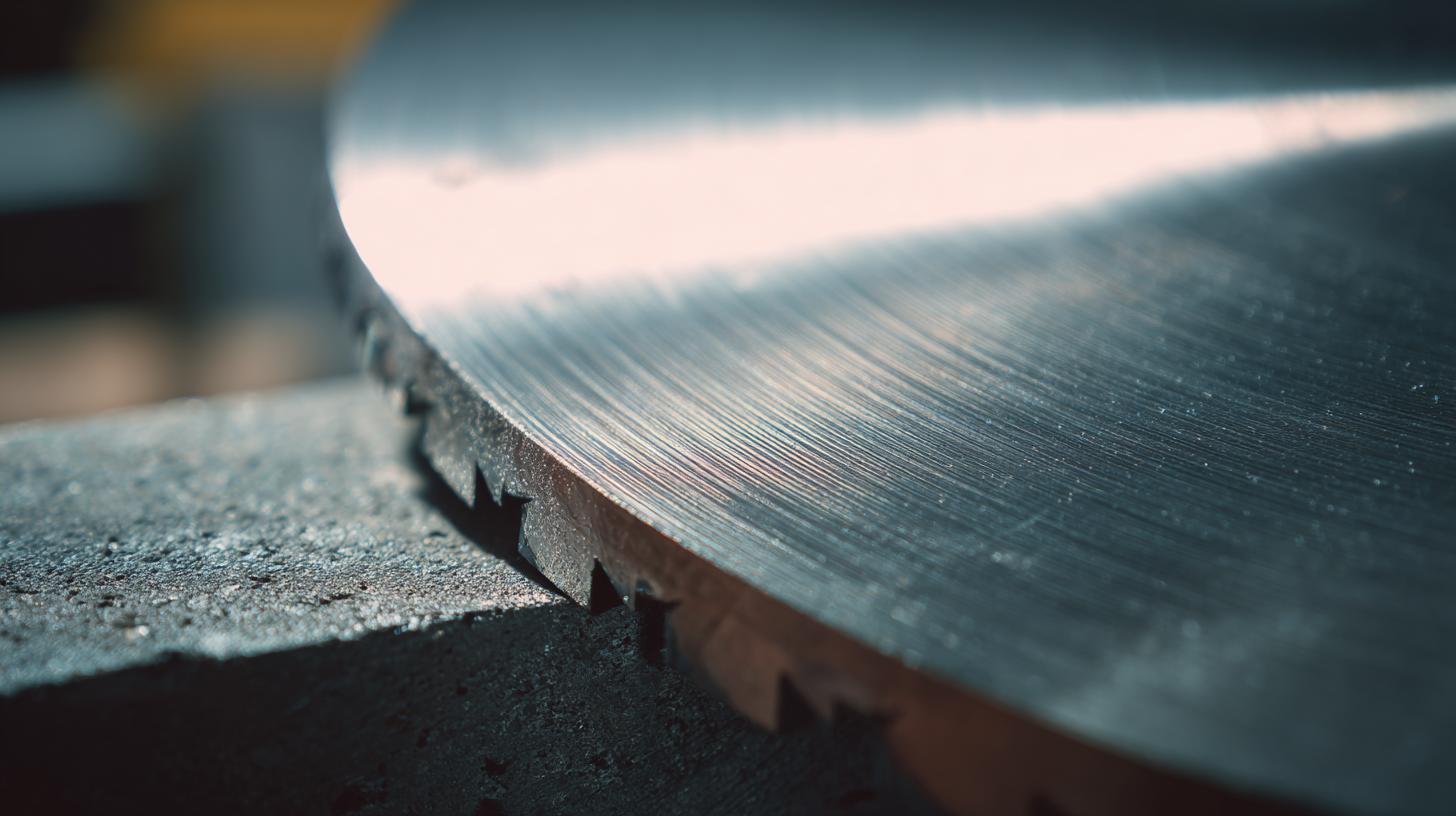

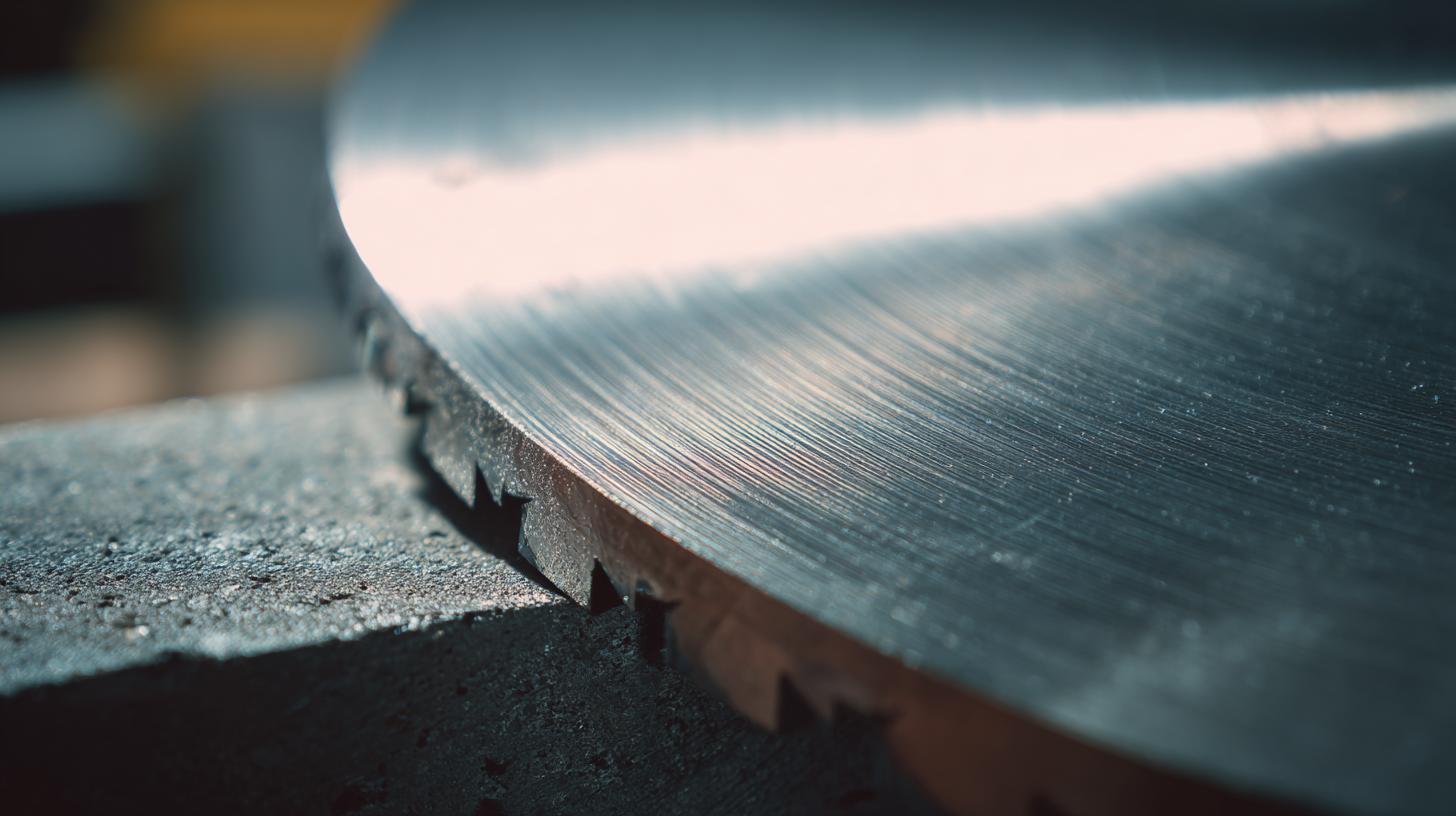

Understanding Round Carbide Blades: Definition and Key Features

Round carbide blades are specialized cutting tools made from high-quality carbide material, known for their exceptional durability and strength. Unlike traditional blades, these circular saw blades are designed to provide a precise and smooth cutting experience, making them ideal for a variety of applications, including woodworking, metalworking, and manufacturing processes. Key features of round carbide blades include their resistance to wear and tear, ability to maintain sharp edges for extended periods, and compatibility with different types of cutting machinery.

When considering the use of round carbide blades, here are some tips to enhance your cutting efficiency. First, always choose the right blade for your specific material and application; this ensures optimal performance and prevents damage to the blade and workpiece. Additionally, maintain the blade by keeping it clean and checking for any signs of wear. Regular maintenance not only extends the blade's lifespan but also enhances cutting precision.

Another important aspect is the blade's teeth configuration. Different teeth setups can significantly impact the quality of the cut you achieve. For example, blades with more teeth provide smoother cuts, ideal for finish work, whereas blades with fewer teeth are suited for faster, rough cuts. Always assess your project's requirements to select the ideal blade design.

The Advantages of Using Round Carbide Blades in Industrial Applications

Round carbide blades have become increasingly popular in industrial applications due to their superior durability and cutting efficiency. These blades are designed with a solid carbide construction, which offers exceptional strength and resistance to wear, making them ideal for cutting through tough materials like metal and hardwood. The high-performance characteristics of round carbide blades enable them to maintain sharp edges longer than conventional blades, resulting in reduced downtime for blade replacements and enhanced productivity on the job.

One of the primary advantages of using round carbide blades is their versatility. They can be utilized in various cutting processes, including slicing, trimming, and ripping, allowing users to tackle a wide range of projects with a single tool. Additionally, the precise cutting ability of these blades minimizes material waste and provides cleaner edges, which is crucial for applications requiring high accuracy. Overall, the adoption of round carbide blades in industrial settings not only boosts operational efficiency but also contributes to cost savings over time due to their long lifespan and performance reliability.

Unlocking the Benefits: The Advantages of Using Round Carbide Blades

Comparative Analysis: Round Carbide Blades vs. Other Blade Types

Round carbide blades are gaining popularity in various industries due to their unique advantages over traditional blade types. One of the main benefits of round carbide blades is their ability to maintain sharpness and resist wear over extended periods, which is crucial when dealing with materials that require precision cutting. In contrast, other blade types, such as bi-metal band saw blades, tend to have a shorter lifespan and may need more frequent replacements, leading to increased operational costs.

When looking for a blade for specific applications, it’s essential to consider tooth types and product design. For example, regular, hook, and skip tooth configurations in bi-metal blades serve different cutting purposes, but round carbide blades can deliver a more consistent performance across various materials. This versatility makes them a preferred choice for industries like woodworking and metal fabrication, where cutting accuracy and durability are paramount.

Furthermore, the growing demand for efficient and reliable cutting tools continues to drive innovation in blade technology, ensuring that round carbide blades remain a competitive option in the market.

Furthermore, the growing demand for efficient and reliable cutting tools continues to drive innovation in blade technology, ensuring that round carbide blades remain a competitive option in the market.

Industry Statistics: Performance Metrics of Round Carbide Blades

In the competitive landscape of industrial cutting tools, round carbide blades have emerged as a superior choice for performance and longevity. According to a recent industry report by the Tooling Association, round carbide blades exhibit an average lifespan 2.5 times longer than their high-speed steel counterparts. With the ability to maintain sharpness over extended periods, these blades can substantially reduce downtime associated with tool changes, translating to increased productivity on the shop floor.

Moreover, performance metrics highlight that round carbide blades typically facilitate cutting speeds that are 30% faster than traditional blades, contributing to enhanced efficiency in manufacturing processes. A survey conducted by the Precision Cutting Research Group indicates that over 70% of manufacturers reported significant improvements in output when switching to round carbide blades. These data points underscore the importance of investing in high-quality cutting tools to optimize operational performance and maintain a competitive edge in the industry.

Choosing the Right Round Carbide Blade for Your Specific Needs

Choosing the right round carbide blade is crucial for maximizing efficiency and achieving desired results in various applications. Round carbide blades are made from advanced carbide materials, which provide superior hardness and wear resistance, making them ideal for cutting through tough materials such as wood, metal, and plastic. According to a recent report by the Industrial Research Institute, the use of carbide tools can increase cutting life by up to 50% compared to conventional steel blades, offering manufacturers an opportunity to reduce costs and improve productivity.

When selecting a round carbide blade, it's essential to consider factors such as the material being cut, the desired finish, and the cutting speed. Different blades are designed for specific tasks, and using the wrong type can lead to suboptimal results and premature wear. For instance, a report from the National Woodworking Association highlights that using the appropriate blade for hardwood versus softwood can enhance cutting efficiency by 30%, ensuring cleaner cuts and less downtime. Additionally, understanding the tooth configuration is vital; finer teeth are suited for precision cuts, while larger teeth can handle rougher work more effectively.

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us

According to a recent report by the

According to a recent report by the  Furthermore, the growing demand for efficient and reliable cutting tools continues to drive innovation in blade technology, ensuring that round carbide blades remain a competitive option in the market.

Furthermore, the growing demand for efficient and reliable cutting tools continues to drive innovation in blade technology, ensuring that round carbide blades remain a competitive option in the market.