Why Solid Carbide Disc Plates Are Essential for Precision Engineering Applications

In the realm of precision engineering, the demand for high-performance tools and components continues to rise, driven by advancements in manufacturing technologies. One such component that has gained significant attention is the Solid Carbide Disc Plate, which is recognized for its superior hardness and wear resistance. According to a recent industry report by Grand View Research, the global carbide tools market is projected to reach USD 15.91 billion by 2027, underscoring the essential role of materials like solid carbide in achieving precision and durability in engineering applications.

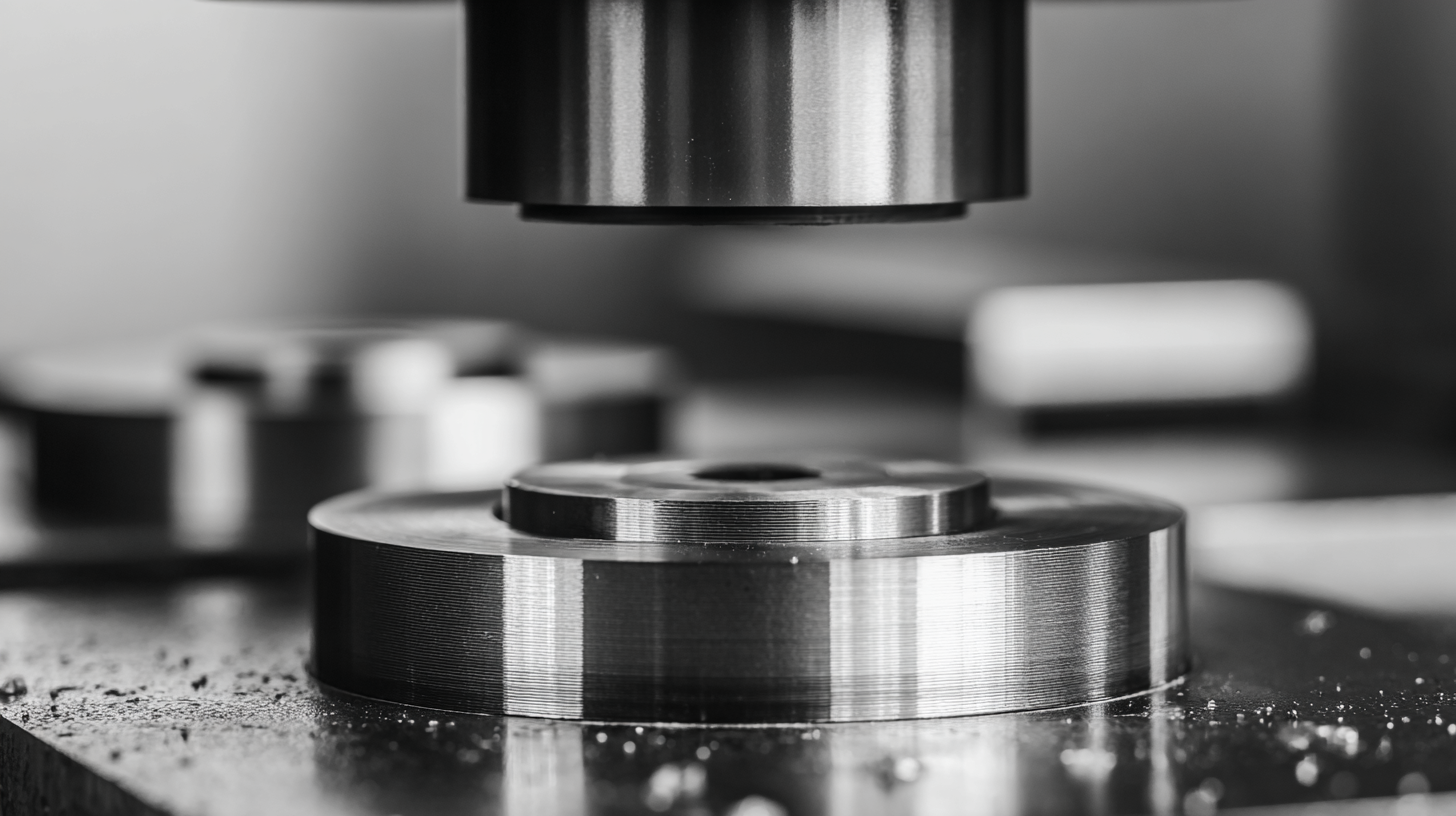

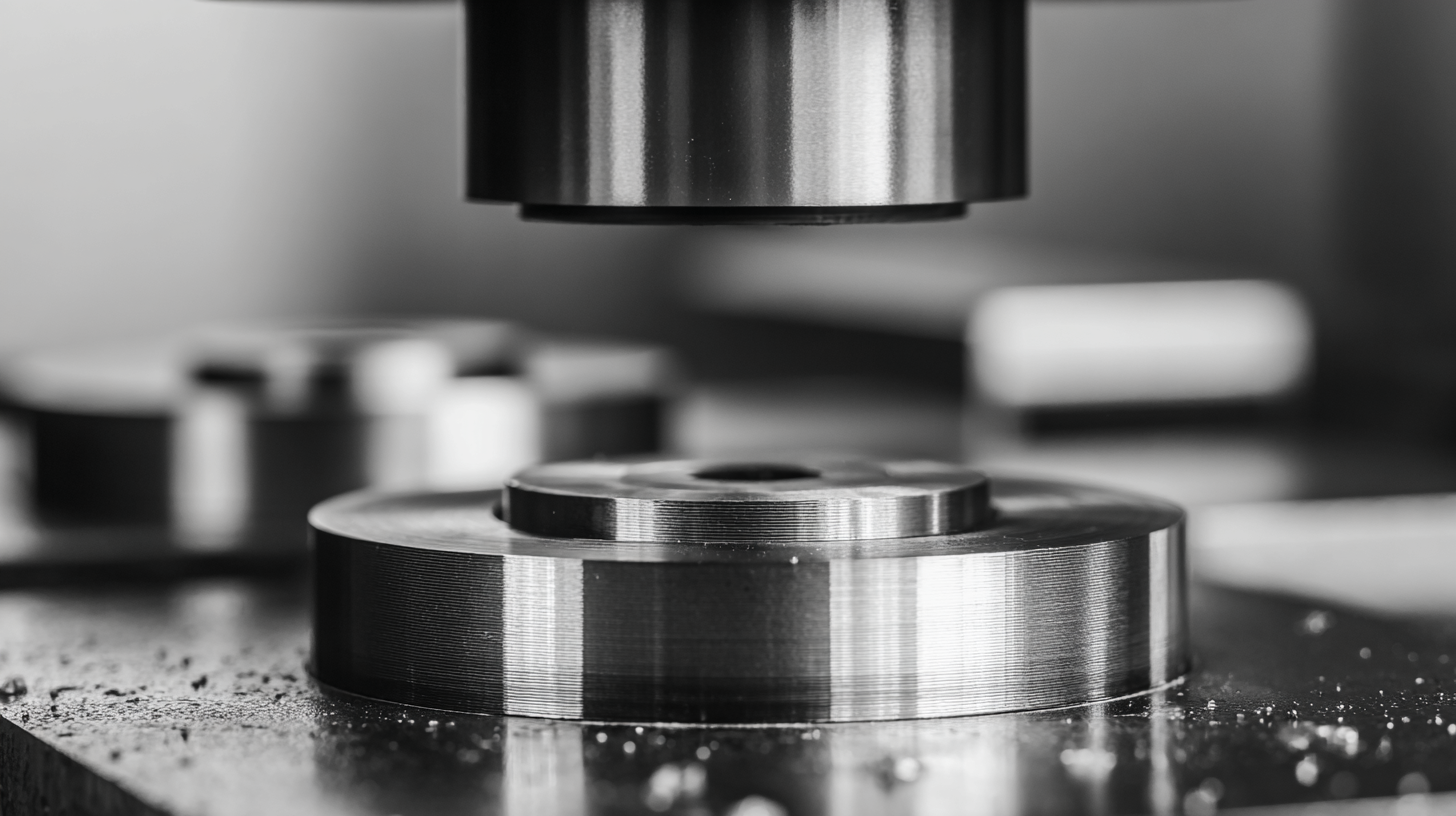

The Solid Carbide Disc Plate stands out not only for its ability to withstand extreme conditions but also for its precision machining capabilities, which are critical in sectors ranging from aerospace to automotive manufacturing. As industries increasingly prioritize efficiency and precision, the reliance on high-quality solid carbide components will only intensify, making Solid Carbide Disc Plates a cornerstone of modern engineering practices.

Advantages of Using Solid Carbide Disc Plates in Precision Engineering

Solid carbide disc plates offer significant advantages in precision engineering applications. Their exceptional hardness and wear resistance are paramount for maintaining high accuracy over prolonged use. Unlike conventional materials, solid carbide can withstand extreme conditions without deformation, ensuring that components retain their precise dimensions. This durability minimizes the need for frequent replacements, leading to cost savings in manufacturing processes.

Furthermore, solid carbide disc plates provide superior thermal stability, which is crucial during high-speed machining operations. This stability reduces the risk of thermal expansion that can affect tolerances and result in defects. Additionally, the smooth surface finish achieved with solid carbide enhances the quality of the final product, leading to improved performance and reliability in various applications. Overall, the unique properties of solid carbide make it an indispensable material for achieving precision in engineering tasks, giving manufacturers a competitive edge in today’s high-tech landscape.

Why Solid Carbide Disc Plates Are Essential for Precision Engineering Applications

Solid carbide disc plates offer numerous advantages in precision engineering, including durability, precision, and resistance to wear. The data below illustrates the performance advantages of solid carbide disc plates compared to other materials in various engineering applications.

Key Applications of Solid Carbide Disc Plates in Various Industries

Solid carbide disc plates have become increasingly vital in precision engineering applications across multiple industries. One of the key areas where these components are indispensable is in machining operations. Their exceptional hardness and wear resistance make them ideal for cutting tools that work on a variety of materials, including metals and composites. This endurance not only enhances the longevity of the tools but also ensures superior surface finishes on the machined parts, which is crucial for applications such as aerospace and automotive manufacturing.

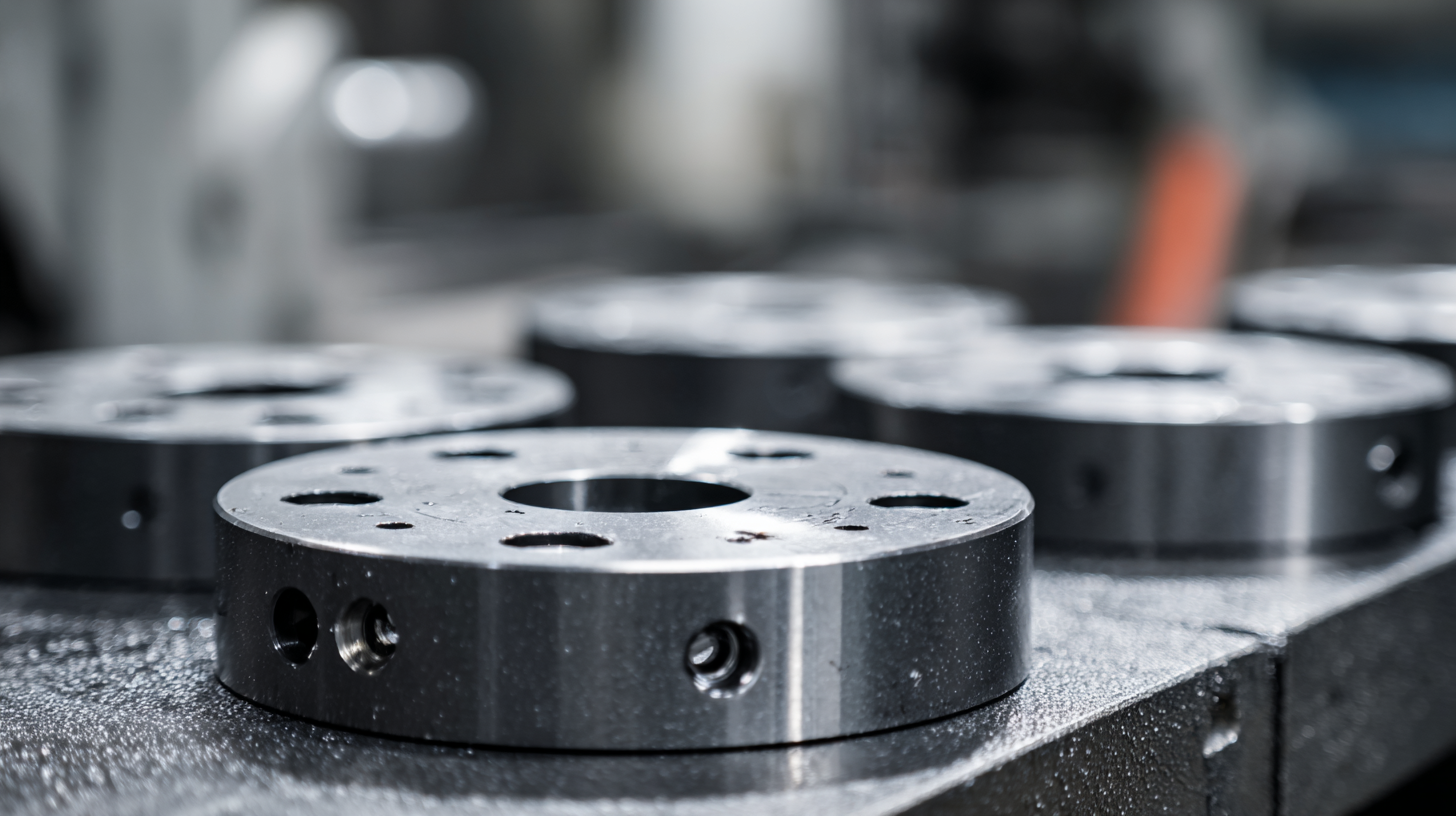

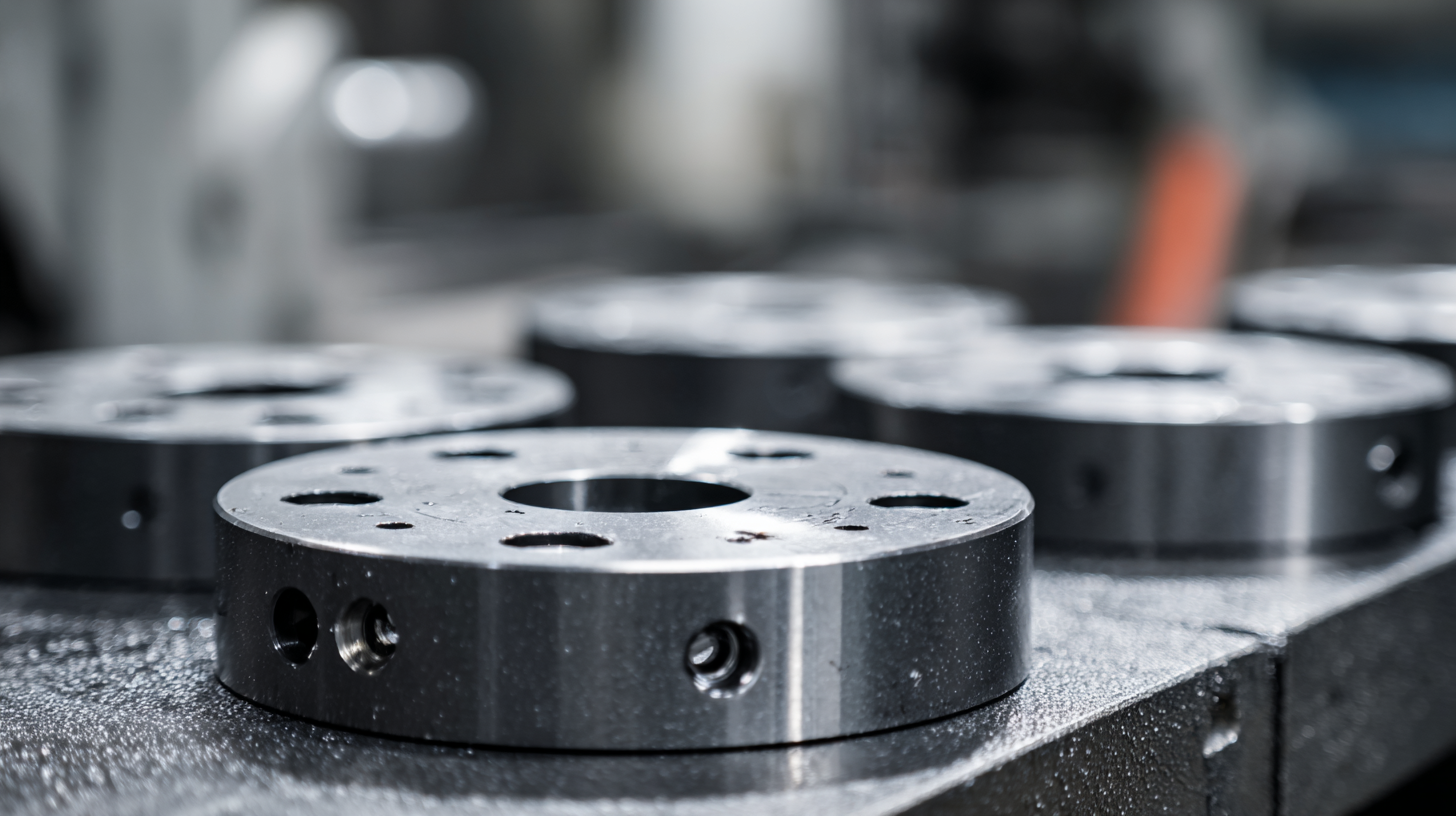

Another significant application of solid carbide disc plates lies in the semiconductor industry. These plates are utilized in the fabrication of intricate components that require high precision and minimal defects. Their thermal stability and resistance to deformation under high pressures make them perfect for processes like wafer slicing and grinding. Additionally, in industries that demand precision measurement, solid carbide disc plates serve as essential components in calipers and other measuring instruments, ensuring accuracy that is paramount for product quality and performance.

Why Solid Carbide Disc Plates Are Essential for Precision Engineering Applications

| Industry |

Key Applications |

Advantages of Solid Carbide Disc Plates |

| Manufacturing |

Cutting tools, milling operations |

High wear resistance, superior cutting performance |

| Medical |

Surgical instruments, dental tools |

Precision machining, biocompatibility |

| Aerospace |

Component manufacturing, turbine blades |

High strength-to-weight ratio, dimensional stability |

| Automotive |

Engine parts, transmission components |

Resistance to high temperatures, precision tolerances |

| Electronics |

Circuit board drilling, semiconductor manufacturing |

Fine detail machining, high precision |

Factors Influencing the Performance of Solid Carbide Disc Plates

Solid carbide disc plates are integral to precision engineering applications due to their superior strength and durability. Several factors influence their performance, beginning with material composition. High-quality tungsten carbide ensures a balance between hardness and toughness, which is essential for maintaining cutting edges and resisting wear over prolonged use. The dispersion of cobalt within the tungsten carbide also plays a critical role in enhancing toughness, allowing the plates to withstand extreme conditions while minimizing chipping and cracking.

Another key factor is the manufacturing process, specifically the sintering technique employed to create these disc plates. Advanced sintering methods, such as hot isostatic pressing, achieve greater density and uniformity in the material, which directly correlates to improved performance in high-stress environments. Additionally, surface finishing techniques can enhance the smoothness of the disc plates, reducing friction and promoting efficient operation. These factors, along with precision engineering standards and quality control measures, ensure that solid carbide disc plates meet the rigorous demands of various applications, from aerospace to automotive engineering.

Comparative Analysis: Solid Carbide vs. Other Materials in Engineering

Solid carbide disc plates are increasingly recognized for their superiority in precision engineering applications when compared to other materials. According to a report by MarketsandMarkets, the global solid carbide tooling market is projected to reach $4.5 billion by 2025, highlighting the growing reliance on solid carbide due to its unmatched hardness and wear resistance. This makes it a favored choice in industries requiring high precision, such as aerospace and automotive manufacturing, where tolerances can be as tight as ±0.002 mm.

When examining the comparison between solid carbide and materials like high-speed steel (HSS) or ceramic, the differences become clear. Solid carbide boasts a hardness rating of over 80 HRC, significantly higher than HSS, which typically ranges from 60 to 67 HRC. This inherent hardness allows solid carbide to maintain sharp cutting edges for extended periods, thereby reducing downtime and increasing productivity. Furthermore, a study by the American Concrete Institute reveals that equipment utilizing solid carbide tools can achieve up to 30% faster machining speeds compared to their HSS counterparts, further validating the advantages of using solid carbide in demanding engineering environments.

Maintenance and Care for Solid Carbide Disc Plates in Precision Applications

Solid carbide disc plates are integral to precision engineering applications, offering exceptional hardness and wear resistance. To maintain their performance, it is crucial to follow proper maintenance and care protocols. Regular inspection for signs of wear or damage is essential, as even minor imperfections can impact precision and efficiency. Cleaning with appropriate solvents and avoiding abrasive materials can help preserve the integrity of the plates. Additionally, proper storage is vital; keeping them in a controlled environment can prevent corrosion and enhance longevity.

Furthermore, the market for advanced materials like Tantalum Carbide (TaC) Coated Graphite Substrates is projected to reach USD 340.54 million by 2034, highlighting the growing demand for durable materials in precision applications. The use of Tantalum Carbide coatings can significantly extend the lifespan of components subjected to harsh conditions. As the industry progresses, the integration of such advanced materials will likely enhance operational efficiencies, emphasizing the need for ongoing maintenance and careful handling of all precision engineering tools, including solid carbide disc plates.

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us