2025 Top 10 Cutting Tool Plates for Precision Engineering and Machining

In the ever-evolving landscape of precision engineering and machining, the importance of selecting the right Cutting Tool Plates cannot be overstated. As industries strive for increased efficiency and higher precision in manufacturing processes, the choice of cutting tools plays a pivotal role. According to a report from MarketsandMarkets, the global cutting tools market is projected to reach USD 26.6 billion by 2025, fueled by advancements in material science and manufacturing technologies. This growth underscores the vital function that high-quality Cutting Tool Plates serve in achieving optimal performance and product quality.

Renowned industry expert Dr. Harold Smith, a leading authority in cutting tool technology, emphasizes, "The evolution of Cutting Tool Plates has significantly impacted machining precision and efficiency. Choosing the right plate not only enhances tool longevity but also drastically improves the overall finish of machined components." As we delve into the top 10 Cutting Tool Plates for 2025, it is essential to consider various factors such as material composition, edge geometry, and coating technology. Understanding these elements will empower engineers and machinists to make informed decisions that enhance productivity and reduce operational costs, setting the stage for excellence in modern manufacturing.

Top 10 Cutting Tool Plates Revolutionizing Precision Engineering in 2025

The year 2025 is set to witness a transformative leap in precision engineering and machining, largely driven by the innovation of cutting tool plates. According to a recent industry report by Technavio, the global cutting tools market is expected to grow by over 4 billion USD from 2021 to 2025, with a significant share attributed to advanced cutting tools designed for precision applications. The integration of smart materials and coatings is enhancing not only the lifespan of these tools but also their performance under extreme conditions.

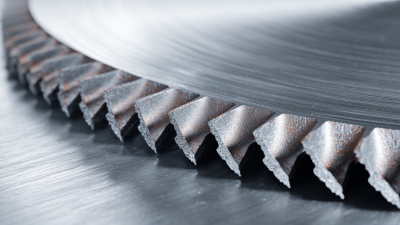

Among the standout innovations are ceramic-coated plates, which offer reduced friction and increased wear resistance, resulting in longer service life and lower operational costs. Moreover, reports from MarketsandMarkets indicate that the adoption of carbide cutting tools in automotive and aerospace sectors alone is projected to grow by more than 6% annually. These cutting tools facilitate exceptionally tight tolerances and superior surface finishes, essential for modern manufacturing requirements, thereby revolutionizing how precision machining is approached in 2025.

Innovative Materials Driving Performance in Cutting Tool Plates

The realm of precision engineering and machining is evolving rapidly, primarily due to innovative materials that enhance the performance of cutting tool plates. These materials not only improve durability and efficiency but also contribute to sustainability in manufacturing practices. Advanced composites, ceramics, and coatings are becoming essential in developing cutting tool plates that can withstand high temperatures and pressures, ultimately leading to superior machining outcomes.

**Tip:** When selecting cutting tool plates, consider options with enhanced wear resistance and thermal stability. Materials such as carbide and high-speed steel are proven to extend tool life and maintain precision in various applications.

In addition to traditional materials, the integration of nanotechnology and graphene-based composites is pushing the boundaries of cutting tool plate performance. These innovations lead to reduced tool wear, lower energy consumption, and better overall machining quality. As the industry embraces these advancements, manufacturers are better equipped to meet the growing demands for accuracy and efficiency in machining operations.

**Tip:** Regularly updating your knowledge on material innovations can enhance your machining processes. Stay informed about the latest trends in cutting tool materials to ensure your operations are at the forefront of technology.

Industry Trends: The Rise of Advanced Coatings for Durability and Precision

In the realm of precision engineering and machining, advanced coatings have emerged as a pivotal trend shaping the performance and longevity of cutting tool plates. According to a recent industry report by MarketsandMarkets, the global coating market is projected to grow from $13.2 billion in 2020 to $18.9 billion by 2025, at a compound annual growth rate (CAGR) of 7.5%. This growth is largely fueled by the demand for enhanced durability and precision in machining applications, making advanced coatings an essential investment for manufacturers aiming to boost productivity and efficiency.

The rise of advanced coatings can be attributed to their ability to significantly reduce wear and friction, leading to improved tool life and surface finish quality. Coatings such as titanium nitride (TiN), zirconium nitride (ZrN), and diamond-like carbon (DLC) are revolutionizing the industry with their exceptional hardness and thermal resistance. According to a survey conducted by the Tooling & Manufacturing Association, more than 60% of manufacturers have reported a 20% increase in tool performance when utilizing cutting tools with specialized coatings. As technology advances, the next generation of coatings promises even greater innovations, aligning with the industry's push towards automation and precision engineering.

Analyzing Market Demand: Key Applications for Cutting Tool Plates in Machining

The global market for metal cutting tools is expected to experience significant growth, rising from $86.24 billion in 2025 to $141.65 billion by 2032, at a compound annual growth rate (CAGR) of 7.3%. This surge can be attributed to the increasing demand for refined precision in machining applications across various industries. Key applications driving this demand include aerospace, automotive, and healthcare manufacturing, where high-quality and reliable cutting tools are essential.

Moreover, the CNC machining services market is anticipated to grow parallelly, with an expected size of $54.02 billion in 2025 and a projected CAGR of 8.04% until 2035. As industries seek to enhance their operational efficiency and output quality, investment in advanced CNC technologies and precision cutting tool plates will become increasingly pivotal.

Tip: When selecting cutting tool plates, consider the specific machining material and application to ensure optimal performance.

Investing in high-quality materials can vastly improve the durability and efficacy of cutting tools. Additionally, staying updated with market trends can guide decision-making in tool selection to align with future demands.

Technological Advancements: AI and Automation in Cutting Tool Plate Design and Production

The integration of AI and automation into the design and production of cutting tool plates is transforming precision engineering and machining. According to a report by Market Research Future, the global AI in manufacturing market is expected to reach USD 16.7 billion by 2026, growing at a CAGR of 50.5%. This surge highlights the increasing reliance on intelligent systems for optimizing processes, reducing waste, and enhancing product quality. AI algorithms are now capable of analyzing large datasets to predict tool wear and performance, facilitating the development of cutting tools that are not only more efficient but also tailored to specific manufacturing needs.

Additionally, automation systems are streamlining the production process of cutting tool plates, resulting in faster turnaround times and improved precision. The International Federation of Robotics reported that the number of industrial robots in manufacturing reached 2.7 million units worldwide in 2020, a number projected to rise significantly in the coming years. By incorporating robotics into cutting tool production, manufacturers can achieve greater consistency and reliability, ultimately leading to reduced labor costs and minimized human error. The combination of AI and automation is not just enhancing production capabilities but also paving the way for innovative designs that meet the rigorous demands of modern engineering applications.

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us