Top Types of Milling Cutters You Should Know About?

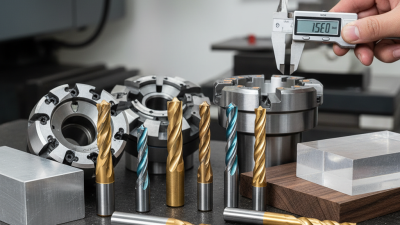

Milling cutter technology plays a vital role in the manufacturing industry. John Smith, a leading expert in precision machining, once stated, "Choosing the right milling cutter can significantly impact production efficiency." With various types of milling cutters available, each serves a specific purpose. Understanding these types can enhance productivity and optimize operations.

Milling cutters vary widely in design and application. Some are designed for flat surfaces, while others handle complex shapes. For instance, end mills are excellent for contouring, whereas face mills excel on flat surfaces. Different materials and coatings also affect performance. It’s crucial to choose a cutter that fits the task at hand.

However, often, manufacturers overlook the importance of proper cutter selection. Falling into a routine, they use the same tools for every job. This can lead to inefficiencies and wasted resources. Every milling cutter brings unique advantages and limitations. Thus, it’s essential to reflect on when to innovate. Recognizing the best type of milling cutter for each job can drive superior outcomes.

Types of Milling Cutters: An Overview of Key Categories

Milling cutters are essential tools in the machining process. They come in various shapes and sizes, each designed for specific cutting tasks. Understanding the key categories of milling cutters can enhance efficiency in any workshop.

End mills are perhaps the most common type. They are versatile and can create complex shapes. These cutters excel in side milling and face milling tasks. However, they may struggle with tougher materials, which can lead to quicker wear.

Ball nose cutters are ideal for contouring and creating rounded edges. They allow for smooth, intricate designs, especially in 3D work. Yet, they tend to leave a poor finish on flat surfaces. Another category, slab mills, is perfect for large-scale stock removal but can be less efficient in tight spaces. Choosing the right cutter is crucial, but the process can feel overwhelming. It requires experience and sometimes trial and error.

Features of End Mills: Essential Tool for Precision Machining

End mills are vital tools in precision machining. Their unique design allows them to cut in all directions, making them versatile. They come in various sizes and shapes. The right choice can enhance productivity significantly. According to recent industry reports, end mills account for over 50% of the tooling market. This shows their importance.

Tip: Choose coated end mills for extended tool life. Coatings can reduce wear and improve performance. This small change can lead to big savings. Keep in mind that using dull end mills is common. They can cause inaccurate cuts and increase production time. Regularly inspect tools to maintain standards.

End mills are often categorized by their number of flutes. Two-flute end mills are best for deeper cuts. They remove material quickly. Contrary to this, four-flute end mills provide a better finish. However, they do not handle deep cuts as well. Finding the right balance is crucial in machining operations. Many ignore the impact of selecting the right flutes. This can lead to operational inefficiencies.

Understanding Face Mills: Applications and Benefits in Industry

Face mills are essential tools in modern machining. They are designed to remove material from flat surfaces. These cutters are typically mounted on a spindle for precision. Their versatility makes them a go-to choice in various industries. Face mills can machine different materials, such as

aluminum, steel, or plastics. Notably, they can achieve smooth finishes and tight tolerances.

One major benefit of using face mills is their efficiency. They cut large areas quickly, reducing production time. However, the depth of cut must be carefully calibrated. Too deep a cut can lead to tool wear or breakage. Moreover, not all face mills are suited for every job. Understanding the specific application is crucial for optimal performance.

In practice, operators can face challenges while using face mills. Issues like uneven wear can arise. Regular maintenance and inspection of the tools are vital. It ensures that they function correctly and safely. By assessing their performance regularly, operators can improve their processes. Investing in quality tools pays off in the long run.

Key Advantages of Ball Nose Cutters for Complex Shapes

Ball nose cutters are essential tools for creating complex shapes in machining.

One key advantage is their ability to produce a smooth finish on curved surfaces.

According to industry reports, ball nose end mills can reduce cycle times by up to

30% when used for 3D contouring. This efficiency is crucial for industries

requiring precision, such as aerospace and automotive sectors.

These cutters maintain a consistent radius, allowing for intricate designs without significant tool wear.

However, it’s essential to consider the feed rates and speed.

Incorrect settings may lead to subpar results or excessive tool wear. Data shows that optimal speeds can extend tool life by

40%, indicating the importance of proper calibration.

Despite their benefits, ball nose cutters do have limitations. They can struggle with deep pockets

and sharp corners. Sometimes, the tool’s geometry may not provide the desired rigidity,

impacting accuracy. It’s important to evaluate project needs thoroughly. Each design may require different approaches. Balancing

complexity with efficiency remains a challenge for many manufacturers.

Comparative Analysis of Milling Cutter Materials and Their Impact on Durability

When selecting milling cutters, the material plays a crucial role in durability. The most common materials include high-speed steel, carbide, and ceramics. High-speed steel offers flexibility, but its wear resistance is limited. It’s suitable for softer materials yet struggles with tougher cuts. Carbide, on the other hand, excels in hardness and can withstand higher temperatures. This creates a more durable cutting edge for demanding tasks.

Ceramic milling cutters also deserve mention. They provide remarkable durability and can handle abrasive materials well. However, they may be brittle and require careful handling. Sometimes, the choice of material might seem straightforward, but it demands attention to the specific application. A mismatch can lead to premature wear or even tool failure.

Understanding these materials is essential. The comparison highlights that no single option fits all scenarios. Each material has its strengths and weaknesses. Reflecting on your specific requirements will ensure better choices. Taking time to evaluate the right cutter can save costs and improve efficiency. This nuanced decision-making process can often be overlooked.

Top Types of Milling Cutters and Their Material Durability Comparison

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us