The Ultimate Guide to Understanding Carbide Blank Rods and Their Applications

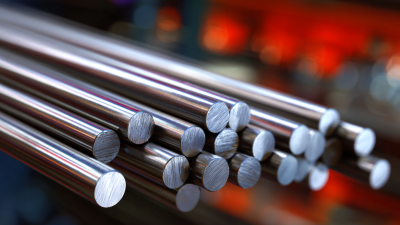

Carbide Blank Rods are essential components in a variety of manufacturing and industrial applications, valued for their superior hardness, durability, and resistance to wear. This ultimate guide aims to delve into the intricacies of carbide blank rods, exploring their composition, production methods, and the diverse range of applications they support.

Understanding these rods is crucial for industries like aerospace, automotive, and tooling, where precision and performance are paramount.

Whether you are a seasoned professional seeking to enhance your knowledge or a newcomer eager to grasp the fundamentals, this guide will provide you with the essential insights needed to effectively utilize carbide blank rods in your projects.

By the end, you will be equipped with practical knowledge on how to choose, handle, and apply carbide blank rods to maximize their potential in your specific field.

Carbide Blank Rods are essential components in a variety of manufacturing and industrial applications, valued for their superior hardness, durability, and resistance to wear. This ultimate guide aims to delve into the intricacies of carbide blank rods, exploring their composition, production methods, and the diverse range of applications they support.

Understanding these rods is crucial for industries like aerospace, automotive, and tooling, where precision and performance are paramount.

Whether you are a seasoned professional seeking to enhance your knowledge or a newcomer eager to grasp the fundamentals, this guide will provide you with the essential insights needed to effectively utilize carbide blank rods in your projects.

By the end, you will be equipped with practical knowledge on how to choose, handle, and apply carbide blank rods to maximize their potential in your specific field.

Understanding the Composition and Properties of Carbide Blank Rods

Carbide blank rods are primarily composed of tungsten carbide and cobalt, which contribute to their exceptional hardness and durability. Tungsten carbide is a compound that combines tungsten and carbon, making it one of the hardest materials available, often surpassing steel in hardness. This unique composition enables carbide blank rods to maintain sharp edges and resist wear, making them indispensable in various industrial applications, particularly in machining and tooling.

In addition to their remarkable hardness, carbide blank rods exhibit excellent thermal stability and resistance to deformation under high temperatures. The cobalt acts as a binder, providing toughness and strength while helping to prevent the material from becoming too brittle. These properties make carbide rods suitable for manufacturing cutting tools, drill bits, and wear-resistant components required in environments that demand high performance. Understanding these properties is crucial for selecting the right materials for specific applications, ensuring efficiency and longevity in manufacturing processes.

Common Manufacturing Processes for Carbide Blank Rods

Carbide blank rods are essential materials in various industrial applications due to their exceptional hardness and wear resistance. The manufacturing processes for these rods are crucial to ensuring their quality and performance. One common method of production is powder metallurgy, which involves mixing tungsten carbide powder with a binder, usually cobalt or nickel. This mixture is then compacted into the desired shape and sintered at high temperatures to achieve density and strength. This method enables the precise control of the material properties, resulting in carbide rods suitable for cutting, drilling, and milling applications.

Another prevalent process is extrusion, where a mixture of tungsten carbide powder and a binding agent is forced through a die to form long rods. This approach allows for continuous production and can accommodate various diameters and lengths tailored to specific needs. Following extrusion, the rods undergo a similar sintering process to enhance mechanical properties. Both powder metallurgy and extrusion methods highlight the versatility and adaptability of carbide blank rods, catering to industries ranging from aerospace to manufacturing, where high-performance materials are a necessity.

Key Applications of Carbide Blank Rods in Industrial Settings

Carbide blank rods are critical components in various industrial applications, particularly in precision cutting and machining sectors. These rods serve as raw materials for producing cutting tools due to their exceptional hardness and wear resistance properties. According to market research published by Custom Market Insights, the global boron carbide market, which includes applications utilizing carbide materials, is projected to reach USD 366.2 million by 2034, growing at a CAGR of 3.8%. This growth is primarily driven by the increasing demand for high-performance materials in the manufacturing industry.

In industrial settings, carbide blank rods are notably utilized in the production of carbide-tipped bi-metal band saw blades. The demand for these saw blades has expanded significantly, fueled by their ability to provide precise cutting for various materials. The carbide tipped band saw blades market is experiencing notable growth, supported by advancements in manufacturing technologies and the push for increased efficiency in industrial processes. Furthermore, innovations in material science, such as new carbide grades designed for machining superalloys, are enhancing the performance of tools made from carbide blank rods, thus further solidifying their importance in modern manufacturing.

Advantages of Using Carbide Blank Rods Over Alternative Materials

Carbide blank rods offer several distinct advantages over alternative materials, making them a preferred choice for a variety of applications in manufacturing and machining industries. One of the most significant benefits is their exceptional hardness and wear resistance, which allow them to maintain their shape and cutting edges even under rigorous conditions. This durability translates into longer tool life, reducing the frequency of replacements and overall production downtime, ultimately leading to cost savings for businesses.

In addition to their strength, carbide blank rods provide superior thermal stability. Unlike some conventional materials that may soften at high temperatures, carbides retain their performance even in extreme heat. This characteristic is particularly crucial in high-speed machining processes, where heat generation is unavoidable. Furthermore, carbide's resistance to chemical wear enhances its versatility, making it suitable for applications involving abrasive or corrosive substances. This combination of properties not only boosts efficiency but also improves the reliability of the tools made from carbide, cementing their status as an essential component in modern manufacturing.

Factors to Consider When Selecting Carbide Blank Rods for Your Projects

When selecting carbide blank rods for your projects, there are several key factors to consider to ensure optimal performance and longevity. First, understand the specific application of the rod, as different grades of carbide are formulated for varying hardness and wear resistance. For instance, heavy-duty machining applications may require a tougher grade, while precision work might benefit from a harder, more brittle material.

Tips: Always assess the working environment and the materials being processed. A proper match between the rod's properties and the project's demands can significantly enhance efficiency and reduce tool wear.

Additionally, the diameter and length of the carbide rod play crucial roles in the machining process. If the rod is too short, it may not provide the necessary reach for your specific task, while an excessively long rod could introduce flexibility, leading to less precise movements.

Tips: Before making a purchase, consider testing a few different sizes to find the most effective dimensions for your needs, as this can prevent unnecessary costs and improve project outcomes.

The Ultimate Guide to Understanding Carbide Blank Rods and Their Applications

| Dimension |

Material Grade |

Applications |

Diameter (mm) |

Length (mm) |

Hardness (HV) |

| Standard |

Cemented Carbide |

Cutting Tools |

6 |

100 |

1800 |

| Medium |

Tungsten Carbide |

Mining Tools |

8 |

150 |

1900 |

| Thick |

Carbide Composite |

Drills |

10 |

200 |

2100 |

| Ultra-thin |

Micro Carbide |

Precision Cutting |

4 |

50 |

2000 |

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us

Carbide Blank Rods are essential components in a variety of manufacturing and industrial applications, valued for their superior hardness, durability, and resistance to wear. This ultimate guide aims to delve into the intricacies of carbide blank rods, exploring their composition, production methods, and the diverse range of applications they support.

Understanding these rods is crucial for industries like aerospace, automotive, and tooling, where precision and performance are paramount.

Whether you are a seasoned professional seeking to enhance your knowledge or a newcomer eager to grasp the fundamentals, this guide will provide you with the essential insights needed to effectively utilize carbide blank rods in your projects.

By the end, you will be equipped with practical knowledge on how to

Carbide Blank Rods are essential components in a variety of manufacturing and industrial applications, valued for their superior hardness, durability, and resistance to wear. This ultimate guide aims to delve into the intricacies of carbide blank rods, exploring their composition, production methods, and the diverse range of applications they support.

Understanding these rods is crucial for industries like aerospace, automotive, and tooling, where precision and performance are paramount.

Whether you are a seasoned professional seeking to enhance your knowledge or a newcomer eager to grasp the fundamentals, this guide will provide you with the essential insights needed to effectively utilize carbide blank rods in your projects.

By the end, you will be equipped with practical knowledge on how to