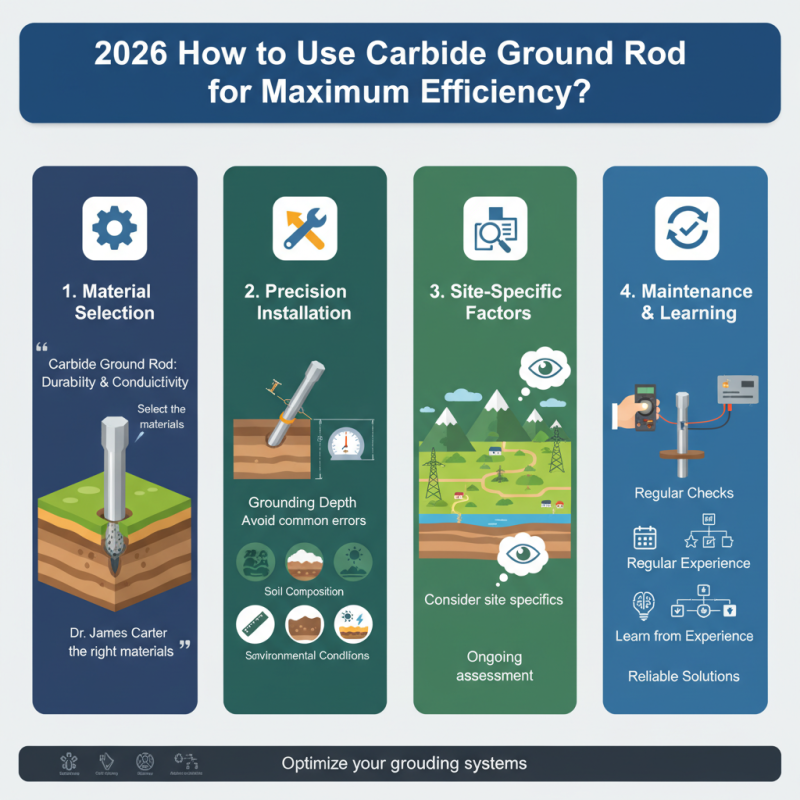

2026 How to Use Carbide Ground Rod for Maximum Efficiency?

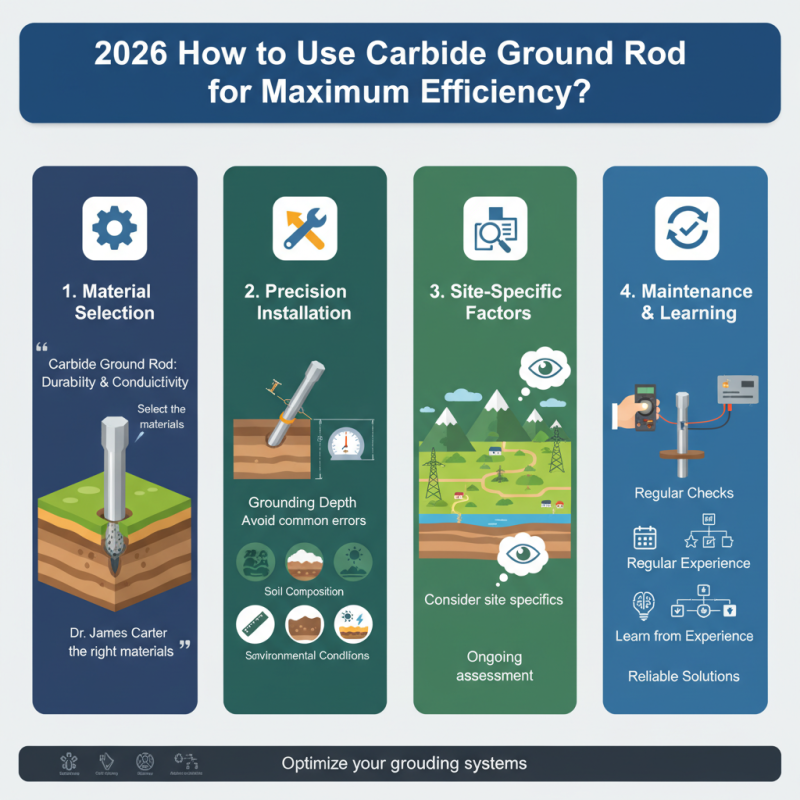

In the evolving landscape of electrical grounding, the use of the Carbide Ground Rod has gained significant attention. According to industry expert Dr. James Carter, "Maximizing the efficiency of grounding systems starts with selecting the right materials." The Carbide Ground Rod, known for its durability and conductivity, emerges as a leading solution for various applications.

However, many users overlook essential factors when implementing these rods. The installation process often lacks precision, leading to inefficiencies in grounding systems. Grounding depth, soil composition, and environmental conditions can affect performance. Dr. Carter emphasizes the need for users to "consider the specifics of their site conditions."

Optimizing the use of Carbide Ground Rods requires attention to detail and ongoing assessment. Conducting regular maintenance checks ensures they meet maximum efficiency. Reflecting on these practices is crucial for achieving reliable grounding solutions in any setting. Making adjustments and learning from experiences can prevent costly mistakes.

Understanding the Basics of Carbide Ground Rods in Electrical Systems

Carbide ground rods play a crucial role in electrical grounding systems. They ensure safety and efficiency by providing a reliable ground connection. Understanding their basics is essential for maximizing their effectiveness. According to recent studies, the resistance offered by ground rods can significantly affect system performance. Ideally, a ground rod should have a resistance level of less than 25 ohms for optimal safety.

The material of carbide rods offers superior conductivity compared to traditional copper. This conductivity allows for efficient dissipation of fault currents. Research indicates that systems using carbide rods experience up to 30% lower resistance levels, enhancing system reliability. Additionally, the durability of carbide means it is less prone to corrosion. However, improper installation can negate these benefits. A common oversight is insufficient depth during installation.

Proper maintenance is also vital for long-term efficiency. Periodic testing of ground resistance can identify potential issues. Many stakeholders underestimate this step, which can lead to increased risks. Industry reports indicate that up to 20% of grounding systems fail due to neglect. Regular inspections can prevent hazardous situations and ensure compliance with regulations. A small investment in maintenance could save significant costs related to equipment failure or safety incidents.

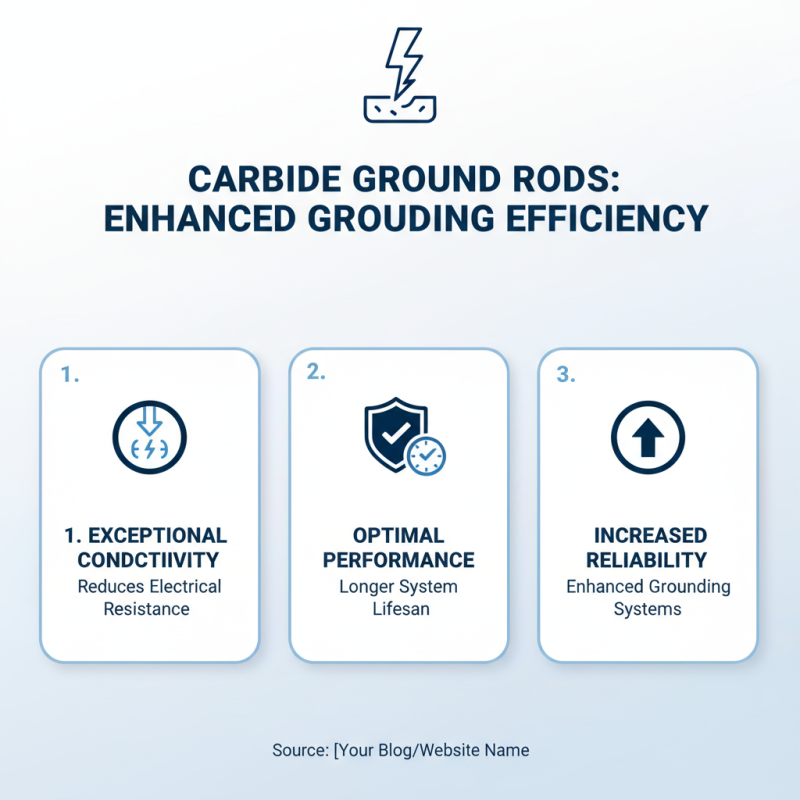

Key Benefits of Using Carbide Ground Rods for Enhanced Grounding Efficiency

Carbide ground rods are becoming increasingly popular for grounding systems. They offer several key benefits that enhance grounding efficiency. One major advantage is their exceptional conductivity. This conductivity helps reduce electrical resistance, ensuring that grounding systems perform optimally for longer periods.

Additionally, carbide ground rods are more durable than traditional materials. They resist corrosion and can withstand harsh environmental conditions. This longevity means fewer replacements and maintenance, which lowers overall costs. Miscalculations in installation or usage could lead to inefficiencies.

Another benefit is their ease of installation. Many users find that carbide rods can be set up more quickly. However, attention to detail is essential for achieving the best results. Experienced installers sometimes overlook the ground rod placement, which can impact effectiveness. Careful consideration of soil conditions and local regulations is vital. Each grounding solution must be customized to ensure maximum efficiency and safety.

Installation Best Practices for Carbide Ground Rods in Various Environments

When installing carbide ground rods, it is crucial to consider the environment. Soil composition can greatly affect conductivity. In sandy or rocky soil, for instance, the conductivity may decrease. According to a 2021 industry report, underground conditions can reduce grounding effectiveness by 30% or more in some areas. Always check local soil conditions before installation.

In urban environments, it is vital to avoid interference from nearby structures. Concrete and asphalt can disrupt grounding efficiency. A study by the Electrical Safety Foundation International found that poorly installed ground rods led to voltage rise issues in 22% of cases. Maintaining a proper distance from such barriers can enhance performance.

Regular inspections are essential. Ground rods can corrode over time, especially in more aggressive soils. Inspecting every few years will aid in identifying wear and tear. A forgotten rod may lose up to 40% of its efficiency without proper maintenance. Using a multimeter can help assess ground resistance continuously. It ensures the system operates at peak efficiency, thereby safeguarding sensitive electronics and human safety.

2026 How to Use Carbide Ground Rod for Maximum Efficiency

This chart illustrates the grounding efficiency of carbide ground rods in various soil types, highlighting the importance of selecting appropriate materials based on environmental conditions for optimal performance.

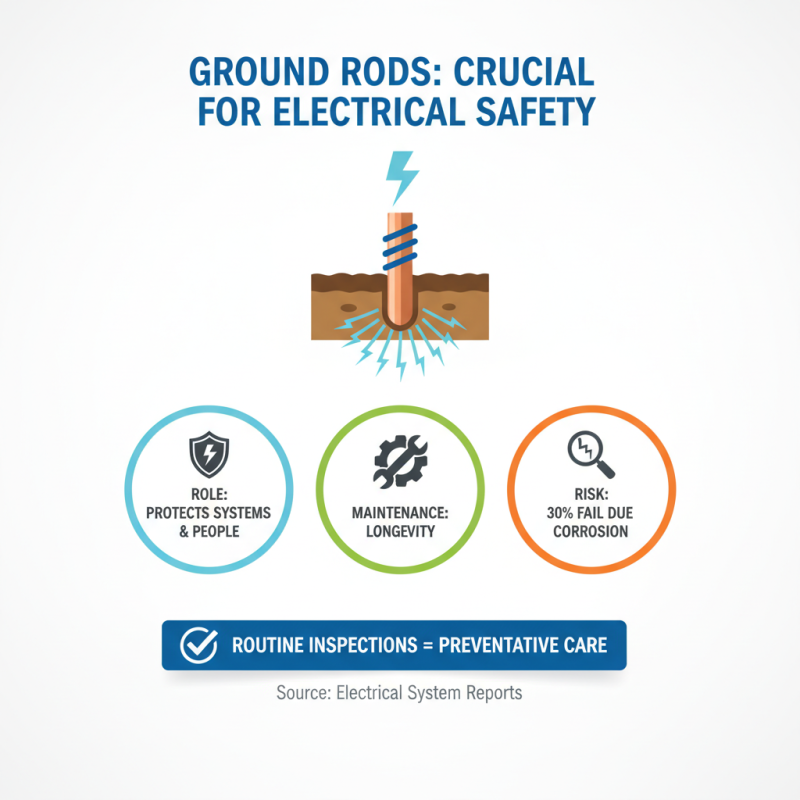

Maintenance Tips to Ensure Longevity and Performance of Ground Rods

Ground rods play a pivotal role in electrical systems. Proper maintenance ensures their longevity and performance. Regular checks can prevent issues that arise from neglect. Reports indicate that nearly 30% of ground rod failures occur due to corrosion. This emphasizes the importance of routine inspections.

One essential tip is to keep the ground rod clean. Dirt and debris can trap moisture, leading to corrosion. Use a wire brush to remove any buildup. It’s also wise to check the connections regularly. Loose connections can create resistance, impacting overall efficiency. Remember, a strong connection means a safe electrical system.

Additionally, monitoring the soil conditions around the ground rod is crucial. Soil resistivity can change over time, affecting performance. Conduct soil tests every few years to identify any issues. If resistivity is high, consider adding more ground rods for better performance. Neglecting soil conditions can lead to inefficiency and potential safety hazards. Consistent care makes a significant difference.

Industry Standards and Regulations Governing the Use of Grounding Rods

Grounding rods play a crucial role in electrical safety. They help prevent electrical shock by directing excess electricity safely into the ground. Understanding industry standards is key for maximum efficiency. Various regulations ensure that grounding systems are reliable and effective in different environments.

Follow local codes and guidelines. Each region may have specific requirements for grounding rod installations. For instance, check if your area mandates a minimum rod length. Typical lengths range from 8 to 10 feet. Ensure you use suitable materials like galvanized steel or copper. Some materials may degrade faster in certain soils.

Tips: Regularly inspect your grounding rod. Look for corrosion or looseness. If you notice any signs of wear, replace it. Also, ensure there’s a connection between the rod and the electrical system. A poor connection can lead to inefficiencies. Keep soil conditions in mind too. High humidity may increase the rod's effectiveness, while dry soil can impede it. Always reflect on these details to ensure safety and efficiency.

2026 How to Use Carbide Ground Rod for Maximum Efficiency? - Industry Standards and Regulations Governing the Use of Grounding Rods

| Dimension |

Description |

Standard/Regulation |

| Material |

High-grade carbide for durability and conductivity |

ASTM A615 |

| Length |

Usually 8 to 10 feet to ensure optimal grounding |

NEC 250.66 |

| Diameter |

Minimum 5/8 inch for effective grounding |

IEEE Std 142 |

| Installation Depth |

At least 8 feet below ground |

National Electrical Code |

| Corrosion Resistance |

Coated for enhanced durability against soil corrosion |

ASTM B117 |

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us