Exploring the Versatility of Blank Carbide Plates: Applications in Modern Manufacturing

The versatility of Blank Carbide Plates has made them an

indispensable component in modern manufacturing, significantly influencing

productivity and

efficiency across various industries. According to a report by

Markets and Markets, the global carbide tools market is projected to reach

USD 13.6 billion by 2026, driven by the

increasing demand for precision tooling and cutting applications.

Blank Carbide Plates, known for their exceptional hardness and

wear resistance, are widely utilized in sectors such as aerospace, automotive,

and metalworking. Their ability to withstand high temperatures and pressures

without deformation makes them ideal for manufacturing processes that require

high durability and precision. As industries continue to evolve, understanding

the diverse applications and benefits of Blank Carbide Plates

will be crucial for companies aiming to enhance their manufacturing capabilities

and maintain a competitive edge in the rapidly advancing market.

The Role of Blank Carbide Plates in Precision Engineering Applications

Blank carbide plates play a pivotal role in precision engineering applications, primarily due to their exceptional hardness and wear resistance. These attributes make them indispensable in industries requiring high-precision tooling and fabrication processes. In modern manufacturing, where tolerances are increasingly stringent, blank carbide plates are utilized to create components that need to withstand extreme conditions, such as high temperatures and corrosive environments. Their stable mechanical properties ensure that machined parts remain reliable and effective over extended periods, making them a favorite choice among engineers and manufacturers alike.

The growing emphasis on efficiency and performance in production lines is fostering the demand for advanced materials like carbide. As industries shift toward incorporating Aluminum Silicon Carbide composites, the significance of blank carbide plates becomes even more pronounced. These plates not only enhance the performance of cutting tools but also contribute to the overall lifecycle of production equipment. As the aluminum silicon carbide market estimates indicate substantial growth through the next decade, the integration of blank carbide plates in precision engineering applications is expected to expand further, opening new avenues for innovation and efficiency in manufacturing processes.

Exploring the Versatility of Blank Carbide Plates in Modern Manufacturing

This chart illustrates the diverse applications of blank carbide plates in various industry sectors. The data highlights the significance of carbide plates predominantly in aerospace and automotive industries, showcasing their crucial role in precision engineering applications.

Innovative Uses of Blank Carbide Plates in Tool Manufacturing

Blank carbide plates are becoming increasingly essential in modern tool manufacturing due to their remarkable versatility and performance enhancements. With innovative design and manufacturing approaches, manufacturers are developing tools that leverage the superior hardness and wear resistance of carbide. For instance, the introduction of advanced carbide grades has significantly improved the functionality of cutting tools, particularly in high-performance applications involving superalloys. These new carbide formulations enable tools to endure harsher conditions, thereby extending their operational life and efficiency.

Applications of blank carbide plates also extend into specialized machining processes, such as the production of high-quality aspheric mirrors. The challenges involved in preparing mirror blanks require precise and durable materials, and carbide plates provide the necessary thermal stability and machining accuracy. Furthermore, the integration of cutting-edge coatings, such as diamond films, has enhanced the performance of carbide inserts, making them more effective for demanding applications. As industries continue to innovate, the role of blank carbide plates in tool manufacturing is set to grow, showcasing their adaptability and essential contribution to the field.

Cost-Effectiveness of Using Blank Carbide Plates in Modern Production

The cost-effectiveness of using blank carbide plates in modern production cannot be overstated. According to a report by MarketsandMarkets, the carbide tooling market is projected to reach USD 22.37 billion by 2026, driven largely by significant cost savings companies achieve through the use of carbide materials. These plates, known for their durability and resistance to wear, allow manufacturers to reduce downtime and maintenance costs while enhancing production efficiency. By integrating blank carbide plates into their operations, businesses can see a return on investment within a short period due to decreased tool replacement frequency.

Tips: One strategy for maximizing the cost benefits of blank carbide plates is to ensure proper tool maintenance and optimization. Regularly monitoring the condition of tools can extend their lifespan, leading to further savings. Additionally, incorporating advanced machining techniques that complement the use of carbide can enhance precision and reduce material waste, ultimately improving the bottom line.

The versatility of blank carbide plates extends into various industries, including aerospace, automotive, and medical manufacturing. Their adaptability enables manufacturers to tailor these plates for specific applications, which can further streamline processes and reduce costs. A study from the American Society of Mechanical Engineers notes that companies employing carbide tools often experience up to 20% lower manufacturing costs in high-volume production scenarios, highlighting the financial advantages related to their implementation.

Enhancing Product Lifespan with Blank Carbide Plates in Industrial Settings

Blank carbide plates have emerged as a vital component in modern manufacturing processes, particularly due to their ability to enhance the lifespan of industrial products. With applications ranging from wear-resistant components to structural parts, these plates offer superior hardness and durability. Industries utilizing these materials benefit from improved product performance and reduced maintenance costs, making them an essential element in various industrial settings.

Blank carbide plates have emerged as a vital component in modern manufacturing processes, particularly due to their ability to enhance the lifespan of industrial products. With applications ranging from wear-resistant components to structural parts, these plates offer superior hardness and durability. Industries utilizing these materials benefit from improved product performance and reduced maintenance costs, making them an essential element in various industrial settings.

The burgeoning market for boron carbide, projected to reach USD 366.2 million by 2034 at a CAGR of 3.8%, indicates a strong demand driven by the need for high-performance materials in manufacturing. Furthermore, the innovative co-manufacturing techniques being developed to produce these value-added products reflect a commitment to cost-effective and environmentally responsible practices. As manufacturers continue to explore the versatility of blank carbide plates, the implications for product longevity and operational efficiency are significant, underscoring their importance in the ever-evolving landscape of modern manufacturing.

Environmental Impact and Sustainability of Blank Carbide Plate Usage

The usage of blank carbide plates in modern manufacturing has drawn attention not only for their performance but also for their environmental impact and sustainability. According to a 2021 report by the International Association of Machining and Manufacturing, the production of carbide tools and plates consumes approximately 2.5 times more energy compared to other materials, highlighting the need for sustainable practices in this sector. However, advancements in recycling processes have made it possible to recover metals from worn carbide products, reducing waste and conserving resources.

Tips: To minimize the environmental footprint, manufacturers should consider implementing a reconditioning process for worn blank carbide plates, rather than opting for new ones. This not only saves energy but also cuts down on raw material extraction, significantly lowering greenhouse gas emissions.

Moreover, embracing practices such as using eco-friendly cutting fluids and energy-efficient machinery can further enhance sustainability efforts. A study by the Environment and Manufacturing Alliance noted that using biodegradable lubricants can decrease harmful emissions by up to 30%. By prioritizing these environmentally-conscious approaches, the manufacturing industry can explore the full potential of blank carbide plates while fostering a more sustainable future.

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

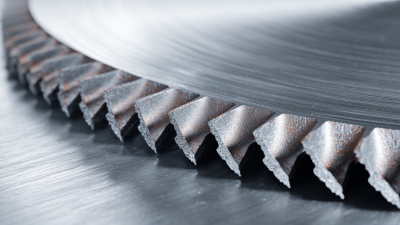

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us