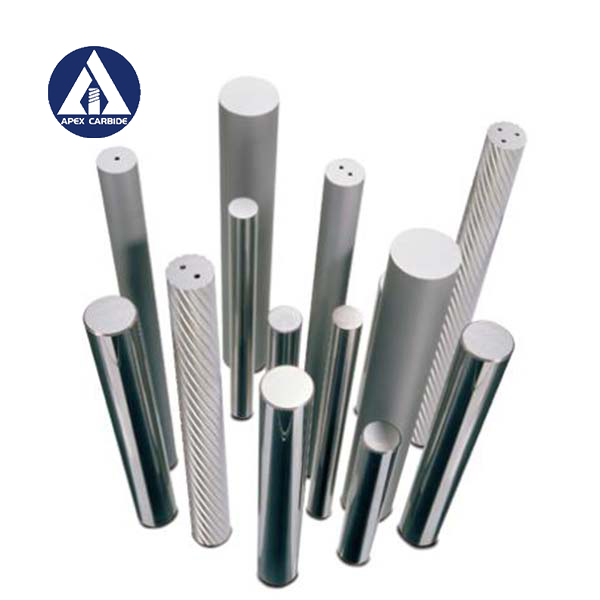

Best End Mills for Aluminum: Precision Tools for Superior Machining Performance

When it comes to machining aluminum, the **End Mill for Aluminum** is the go-to tool for achieving exceptional results. This specialized end mill is engineered to navigate the unique challenges associated with cutting aluminum, ensuring smooth finishes and efficient chip removal. Its durable design supports high-speed machining while maintaining precision, making it an invaluable addition to any toolkit. Whether handling intricate designs or large-scale projects, this end mill consistently delivers quality performance. With enhanced cutting capabilities, it not only increases productivity by saving time but also minimizes tool wear. For those prioritizing quality and efficiency in their machining operations, the **End Mill for Aluminum** by Jiangxi Apex Carbide Co., Ltd. stands out as a trusted, reliable choice.Methods To Choose End Mill For Aluminum Factory Supplier

When selecting end mills for machining aluminum, particularly for suppliers like Jiangxi Apex Carbide Co., Ltd, it's crucial to consider several key factors that ensure optimal performance and efficiency. Firstly, the choice of material is paramount. Carbide end mills, known for their hardness and durability, are ideal for aluminum applications due to their ability to maintain sharp cutting edges at higher speeds. At Jiangxi Apex Carbide, we specialize in high-quality cemented carbide products, offering a range of end mills designed specifically for aluminum processing. Next, consider the design geometry of the end mill. Features such as flute count, helix angle, and cutting edge radius significantly affect the cutting process. A higher helix angle can help enhance chip removal, while a lower flute count may increase strength for heavier cutting applications. At our facility, we produce customized end mills tailored to meet the specific needs of varied machining tasks, ensuring efficiency and precision. Finally, the coating of the end mill plays a vital role in performance enhancement. Coated Carbide Tools can reduce friction and increase wear resistance, leading to longer tool life and improved surface finish. With our annual output reaching 2000 tons of carbide blanks, Jiangxi Apex Carbide is committed to providing global buyers with the right solutions for their aluminum machining needs. Partnering with us means accessing advanced tooling expertise and high-quality products designed to meet the demands of modern manufacturing.

Methods To Choose End Mill For Aluminum Factory Supplier

| Criteria | Recommended Options | Notes |

|---|---|---|

| Material Type | Aluminum Alloys | Choose mills designed for aluminum to reduce wear. |

| Flute Count | 2-3 Flutes | Fewer flutes help with chip evacuation. |

| Coating | TiN, TiAlN | Coatings can reduce friction and improve tool life. |

| Diameter | 1/4", 1/2" | Choose diameter based on workpiece requirements. |

| Cutting Speed | 1000-2000 SFM | High speeds boost performance in aluminum machining. |

| Depth of Cut | 0.025" - 0.1" | Shallower cuts reduce stress on the tool. |

How To find End Mill For Aluminum Supplier Products

L

Leo N. Martinez

Highly satisfied with the quality and after-sales support. They really know how to treat their customers right!

17 June 2025

S

Sophia W. Taylor

The professionals who assisted me were not only friendly but also very knowledgeable, putting my mind at ease.

20 June 2025

S

Sofia B. Wright

Absolutely satisfied with this purchase. The quality is unmatched, and the staff were exceptionally helpful!

10 May 2025

C

Charlotte M. Lee

The product simply outperforms my expectations, and the service team was always there when I needed them.

21 May 2025

M

Mackenzie V. Frank

The quality of the item is outstanding. The service staff handled my questions with expertise.

01 July 2025

P

Paisley W. Reed

Marvelous product quality! The insight and assistance from the staff were invaluable.

03 July 2025