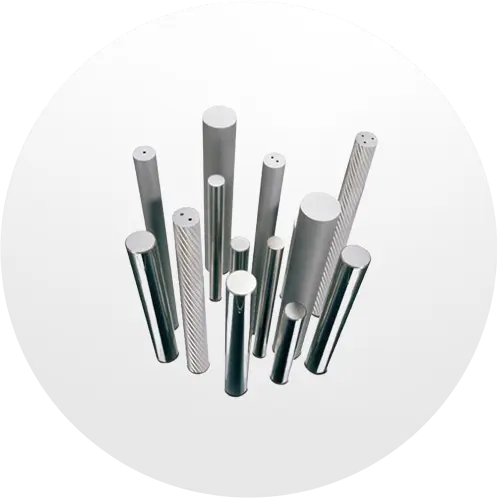

Cemented Carbide Milling Cutters

1.Universal Performance Factors of Milling Cutters

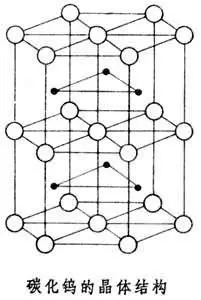

(1)High Hardness and Excellent Wear Resistance

The cutting section of milling cutters must exhibit hardness exceeding that of the workpiece material to enable efficient penetration and stable cutting. Cemented Carbide Milling Cutters, through precise ratio of tungsten carbide particles and cobalt binder phase, achieve a hardness of 89-93HRA (approximately 74-81HRC), significantly higher than most metallic materials. At the micro level, ultrafine-grain cemented carbides, with their denser microstructure, reduce wear rates by 30%-50% compared to conventional materials when machining hard materials like cast iron and quenched steel, effectively extending tool life.

(2)Superior High-Temperature Stability

In high-speed milling operations, the cutting edge temperature can soar to 600-1000℃, requiring tool materials to have excellent heat resistance. Cemented carbides, relying on the high-temperature stability of the WC-Co alloy system, maintain a hardness of over 80HRA at 800℃, ensuring the cutting edge does not soften or adhere at high temperatures. Combined with coating technologies, their oxidation resistance temperature can be further increased to 1100℃, enabling efficient dry cutting or continuous high-temperature machining.

(3)High Strength and Impact Toughness

Instantaneous impact forces and vibrations during cutting easily cause tool failure, so tool materials must have high strength to prevent fracture and damage. Cemented carbide milling cutters balance strength and toughness through optimized composition and structural design.

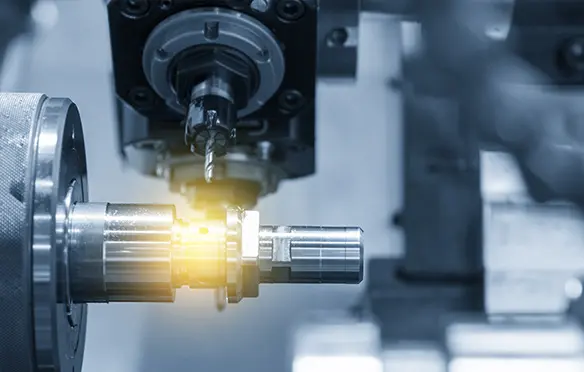

2. Main Applications of Milling Cutters

Cemented carbide milling cutters, with their high hardness, strong wear resistance, and excellent thermal stability, serve as core tools in the mechanical machining field. Their application spans a wide range of materials with specific considerations:

For ferrous metals—including gray cast iron, carbon steel, and alloy steel—cemented carbide milling cutters enable efficient cutting. For quenched steel below HRC50, these cutters achieve precise machining through their excellent hardness and wear resistance. When machining non-ferrous metals, selection should be based on material properties. For example, YG-series alloy cutters are preferred for aluminum alloys to minimize tool wear and improve surface finish, while cemented Carbide Cutters also exhibit reliable cutting performance for copper alloys. In non-metallic material machining, ultrafine-grain alloy cutters are used for graphite (due to its brittleness) and engineering plastics (due to their special properties), minimizing material chipping and tool adhesion to ensure machining accuracy.

In terms of machining types, cemented carbide milling cutters are versatile for operations like face milling, slot milling, and thread milling, making them indispensable in key industrial manufacturing sectors. In automotive manufacturing, they are widely used for mass production of engine cylinder blocks, ensuring dimensional accuracy and surface finish of complex cavities. In aerospace, they efficiently machine aluminum alloy structural components to meet strict requirements for lightweight and high-strength aviation parts. In mold manufacturing, they enable precise forming of complex surfaces in mold cavities, providing a reliable guarantee for mass production of high-quality molds.