- Solid Carbide Rods

- Carbide Rods with coolant holes

- Carbide Rods with Two Helix Holes

- Tungsten Carbide Flats

- Solid Carbide Discs

- Tungsten Carbide anti-vibration cylindrical shafts

- Non-standard Customized Carbide Blanks

- Solid Carbide Circular Saw Blade

- Solid Carbide Woodworking Blade

- Solide Carbide End Mills

- Solid Carbide Drills

- Carbide Rotary Burrs

- Customized Carbide Tools

0102030405

65 HRC Tungsten Solid Carbide Milling Cutters with NaNo Blue coating

Our Main Types of carbide end mills

1.Flat End Mills

2.Ball Nose End Mills

3.Corner Radius Milling Cutter

4. Roughing End Mills

5.Other Customized End Mills

Details Show

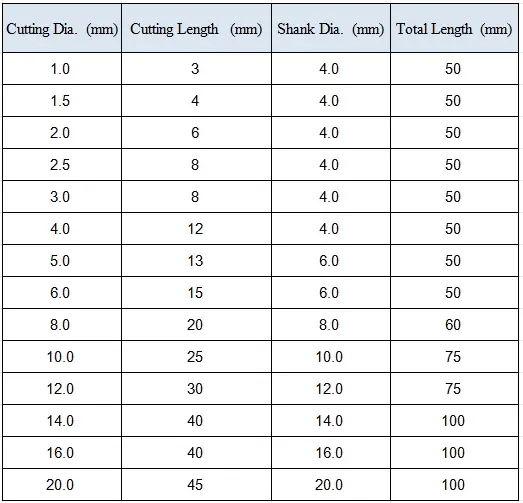

Our Normal Size

Our Advantages

1.We have aroung 20 years production and management experience and have complete industrial chain from tungsten powder to precision milling tools.

2.We has obvious technology advangages,we always maintained the advanced position in technological R&D capability in China,and has owned a provincial-level technology center,as well as an analysis and test center,with 112 personnel holding senior professional and technical titles,master’s degree or above.Meanwhile,we have set up a professional laboratory to test the properties and parameters for tungsten carbide powder and tungsten carbide alloys.

3.We have stable and reliable manufacturing system,which with advanced process equipments like ROLLOMATIC processing machine,Walter machine,Anka machine,DJ machine; talented professionals and perfect quality assurance system.

4.Perfect quality assurance system.

We strictly implements the ISO9001:2015 qualitymanagement system,and implements the whole staff quality responsibility system to ensure continuous and efficient service to clients.

5.Super 100% original raw material

Normally, we use our own rods or GESAC Rods(China Mainland)

6.Super Coating

Nano Blue coating for high-hard metal which HRC is between 55 degree to 68 degree

7.Advanced Equipment

Rollomatic for small end mills

Walter or AnKa for normal size end mills