Premium Aluminum End Mills for Precision Machining and Superior Quality Tools

When reliable tools for precision machining are essential, the Aluminum End Mill stands out as a game changer. Specifically designed for aluminum alloys, it ensures clean cuts and minimal burr formation. Its advanced carbide construction provides exceptional durability and sharpness, resulting in longer tool life and reduced downtime. With a variety of sizes and designs available, finding the perfect fit for your projects is effortless. The consistent quality and innovative engineering from Jiangxi Apex Carbide Co., Ltd. are commendable. This end mill eliminates blending issues and offers excellent chip removal, keeping your work surface clean. For those who prioritize machining efficiency and superior finishes, this tool is essential. Competitive pricing and outstanding support further reinforce its value for machining needs, making it an important asset for enhancing production capabilities.Why Choose Aluminum End Mill Manufacturer Supplier

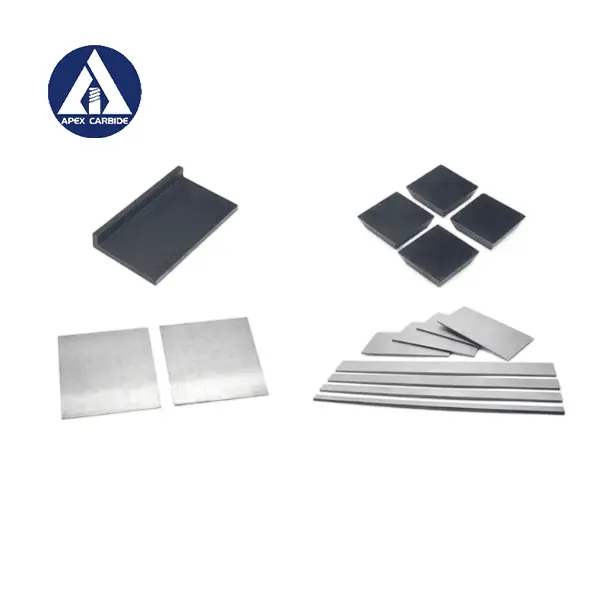

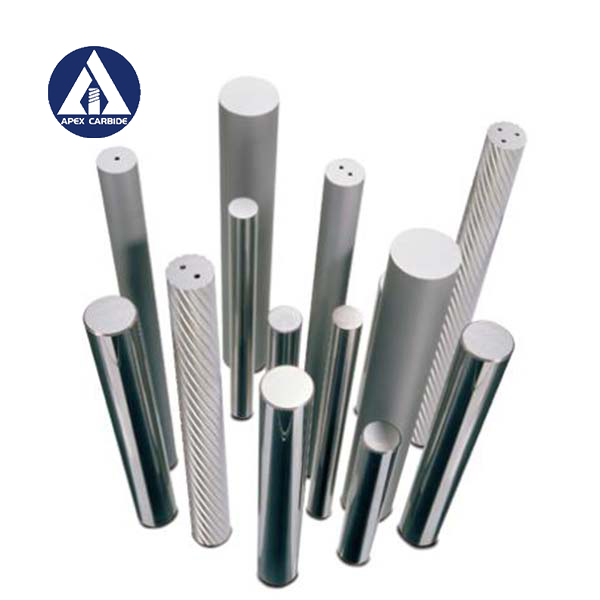

When it comes to selecting an aluminum end mill manufacturer supplier, the choice can significantly impact the quality and efficiency of your machining processes. Jiangxi Apex Carbide Co., Ltd is a leading provider of high-quality cemented carbide products, making us an ideal partner for those seeking reliable and durable machining tools. With an annual output of 2000 tons of various Carbide Blanks, we ensure that our clients receive only the best materials, tailored to their specific production needs. Our comprehensive product range includes carbide rods, plates, blades, and circles, all designed to enhance performance and longevity. The advanced manufacturing techniques employed at Jiangxi Apex Carbide guarantee precision and consistency, so you can focus on achieving your operational goals without worrying about tool failure. Choosing us means benefiting from our expertise, competitive pricing, and an unwavering commitment to customer satisfaction, making us the preferred choice for global buyers looking for quality and reliability in aluminum end mills. Partnering with Jiangxi Apex Carbide Co., Ltd not only provides access to world-class products but also to a dedicated team that understands the challenges of modern manufacturing. We are here to support you every step of the way, ensuring that you have the right tools at your disposal to improve productivity and reduce downtime. Elevate your machining capabilities today by choosing a supplier that prioritizes excellence and innovation—choose Jiangxi Apex Carbide as your trusted aluminum end mill manufacturer.

Why Choose Aluminum End Mill Manufacturer Supplier

| Feature | Description | Benefits |

|---|---|---|

| High Precision | Manufactured with CNC technology for tight tolerances. | Ensures superior finish and dimensional accuracy. |

| Material Quality | Made from high-grade aluminum alloy. | Provides durability and excellent performance. |

| Cost-Effectiveness | Affordable pricing without compromising on quality. | Reduces overall manufacturing costs. |

| Wide Range of Products | Various sizes and shapes available. | Suits different machining needs and applications. |

| Customization Options | Custom designs and specifications available. | Meets specific customer requirements effectively. |

| Technical Support | Expert guidance and assistance available. | Helps optimize machining processes. |

How To find Aluminum End Mill Factory Products

D

David J. Perez

Quality and service that you can rely on! The follow-up by the support team was impressive.

06 July 2025

J

Jennifer K. Rivera

This purchase was worth every penny! The professionalism displayed by the support team was impressive.

25 May 2025

R

Ryan F. King

The craftsmanship is remarkable! After-sales service personnel made sure that I was completely satisfied.

23 May 2025

A

Aiden T. Carter

Fantastic product quality; equally impressive was the quality of service provided by the team.

07 June 2025

M

Mason J. Sanchez

This item has exceeded my expectations. The after-sales support is second to none.

16 May 2025

M

Maria K. Bennett

Fabulous product quality! Timely and professional support made it even better.

22 June 2025