China OEM Hard Alloy - Carbide Rotary Burrs with High Quality Short Delivery Time and Low MOQ – CEMENTED CARBIDE

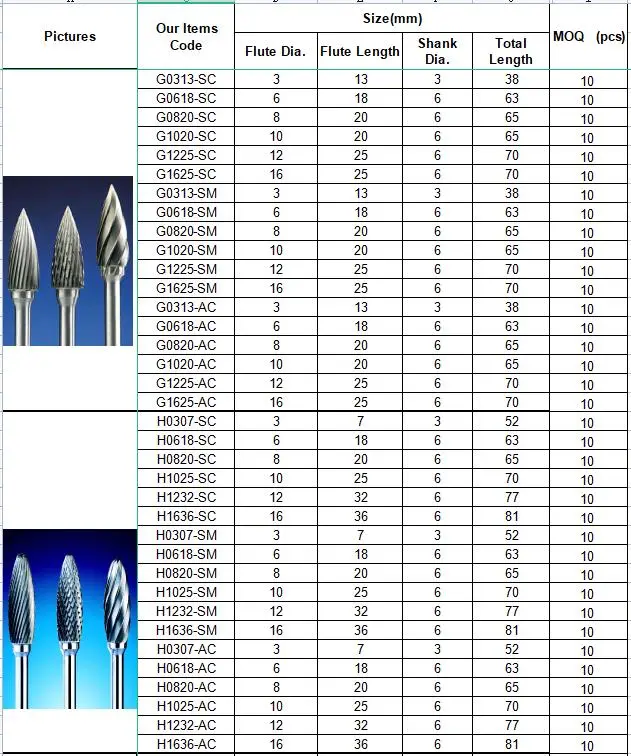

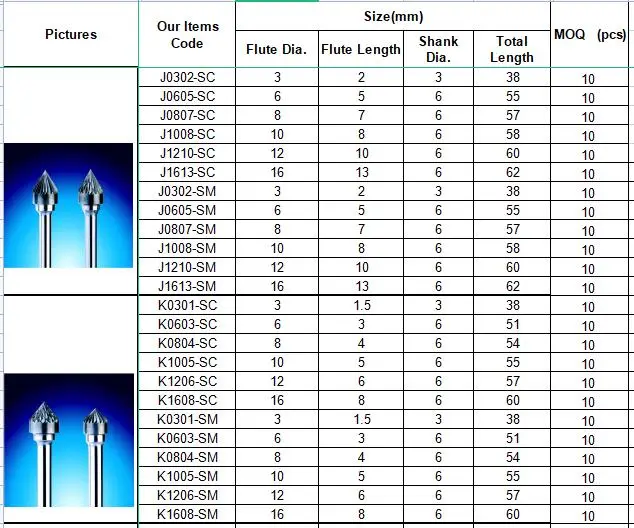

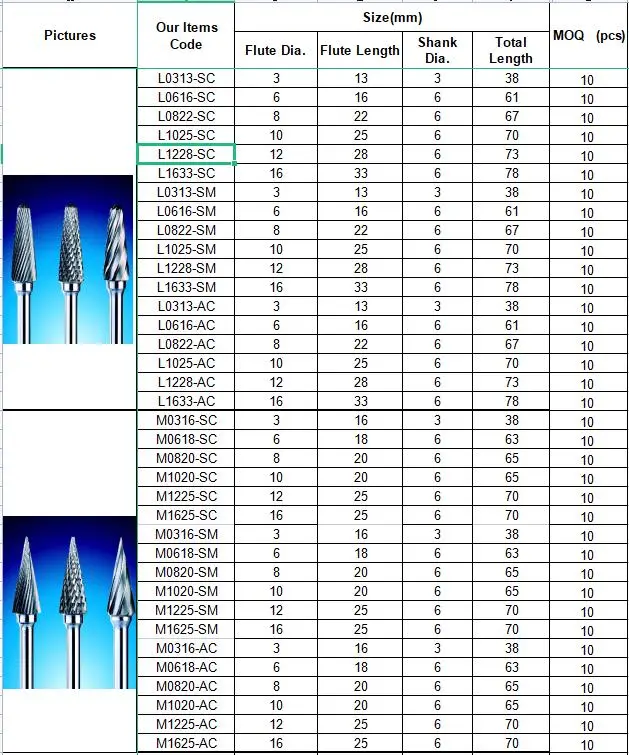

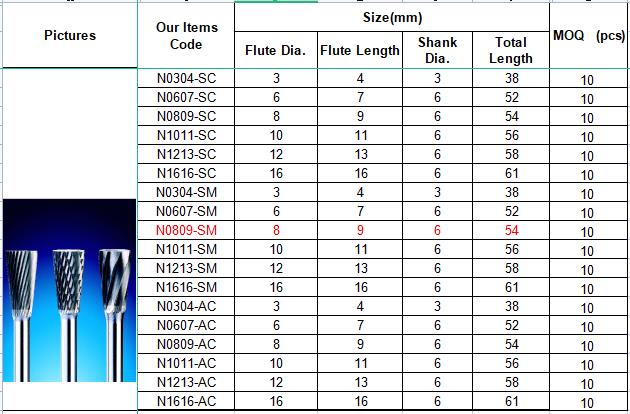

China OEM Hard Alloy - Carbide Rotary Burrs with High Quality Short Delivery Time and Low MOQ – CEMENTED CARBIDE Detail:

1. High hardness

2. High abrasion and corrosion resistance.

3. High pressure resistance

4. High temperature resistance

5. Products with advanced equipment and perfect workmanship

1.We have more than 50 years production and management experience and have complete industrial chain from tungsten powder to precision milling tools.

2.We has obvious technology advangages,we always maintained the advanced position in technological R&D capability in China,and has owned a provincial-level technology center,as well as an analysis and test center,with 112 personnel holding senior professional and technical titles,master’s degree or above.Meanwhile,we have set up a professional laboratory to test the properties and parameters for tungsten carbide powder and tungsten carbide alloys.

3.We have stable and reliable manufacturing system,which with advanced process equipments like ROLLOMATIC processing machine,Walter machine;DJ machine; talented professionals and perfect quality assurance system.

4.Perfect quality assurance system.

We strictly implements the ISO9001:2015 qualitymanagement system,and implements the whole staff quality responsibility system to ensure continuous and efficient service to clients.

5.Super 100% original raw material

Normally,we use NCC Rods(our own rods) or GESAC Rods(China Mainland)

Also,imported rods like Sandvik rods could be used according to your requirement.

6.Advanced Equipment

Rollomatic for small burrs

Walter for non-standard burrs

DJ machine for standard burrs

7.Short Delivery Time

We have large production capacity,so can finish your order in very short time,most in about 10days.

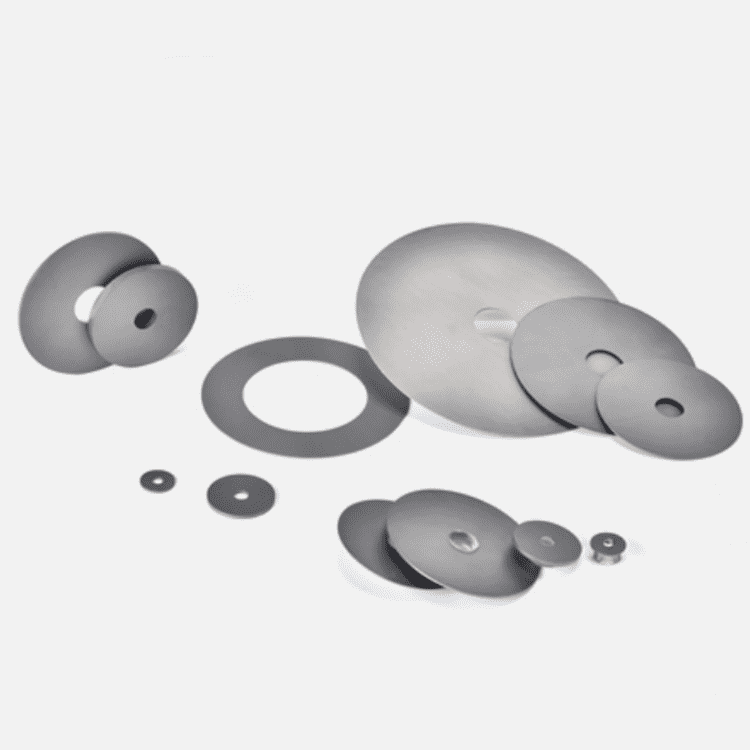

Product detail pictures:

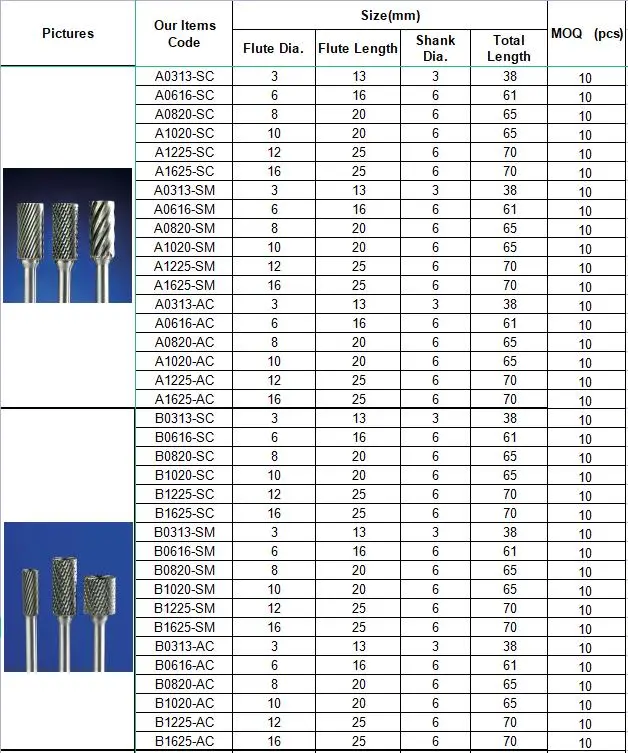

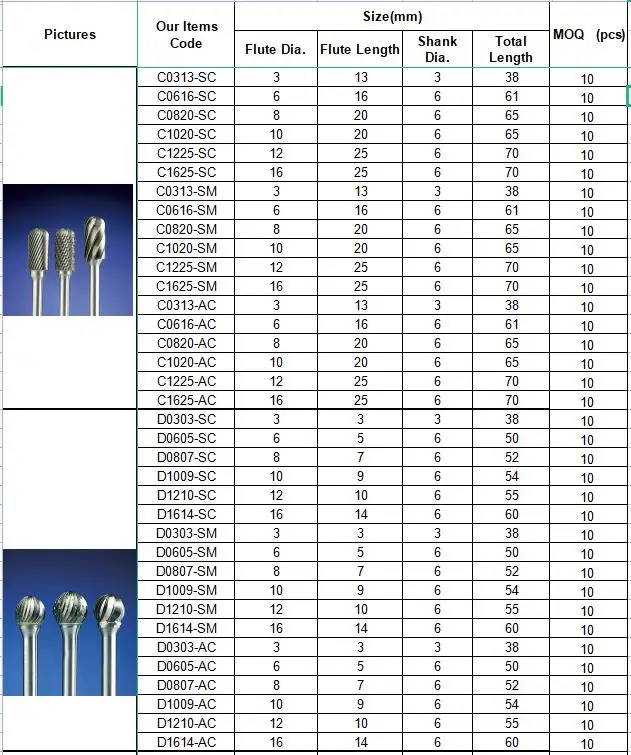

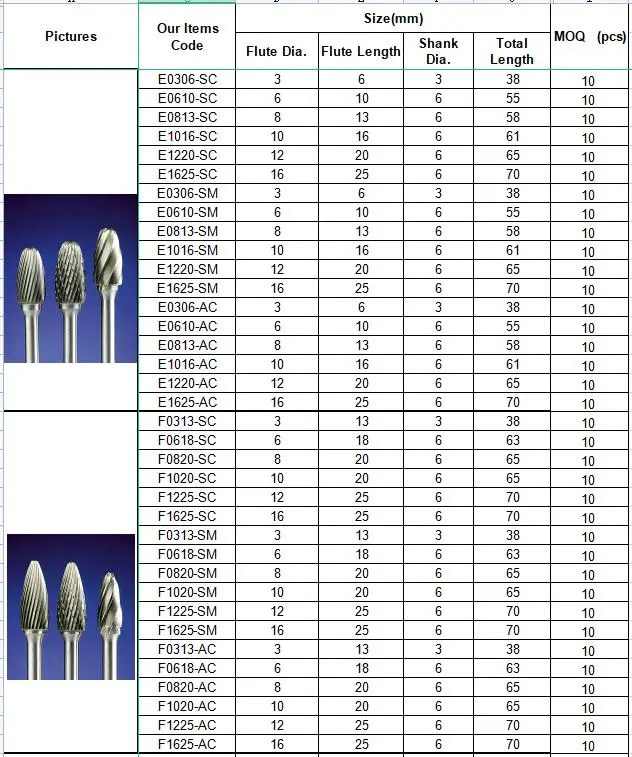

Related Product Guide:

carry on to further improve, to guarantee merchandise high-quality in line with market and buyer standard necessities. Our organization has a top quality assurance procedure have already been established for China OEM Hard Alloy - Carbide Rotary Burrs with High Quality Short Delivery Time and Low MOQ – CEMENTED CARBIDE , The product will supply to all over the world, such as: Afghanistan, Detroit, Las Vegas, We insist on the principle of "Credit being primary, Customers being the king and Quality being the best", we are looking forward to the mutual cooperation with all friends at home and abroad and we will create a bright future of business.

By Hazel from Albania - 2018.02.21 12:14

By Hazel from Albania - 2018.02.21 12:14

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!

By Myra from Belgium - 2018.11.28 16:25

By Myra from Belgium - 2018.11.28 16:25