Global Tungsten Heart: Jiangxi’s Export Edge in carbide

🌏 China's Hard carbide Industry: Jiangxi's Strategic Advantages

For global manufacturers seeking resilient supply chains and advanced materials, Jiangxi Province has established itself as a critical hub for Hard Alloy production. Its competitive strengths are anchored in five core areas, detailed below for international stakeholders:

⛰️ 1. Resource Sovereignty

-

Global Tungsten Reserves: Southern Jiangxi, particularly Ganzhou, holds >60% of the world's tungsten reserves, with ore quality recognized as the industry benchmark56.

-

End-to-End Control: Integrated operations—from mining to refining—ensure raw material security, mitigating geopolitical supply risks16.

-

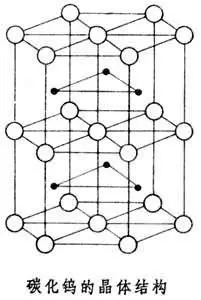

Advanced Powder Processing: Capabilities in producing nano-scale (0.08μm) to coarse (100μm) tungsten powders enable aerospace-grade alloys, positioning China’s powder technology alongside EU/Japan standards6.

🔗 2. Integrated Industrial Ecosystem

-

Vertical Integration: Unique "mine-to-machine" cluster spanning mining, powder metallurgy, alloy manufacturing, and precision tooling within a single province. For example:

-

Upstream: High-purity APT (ammonium paratungstate) and tungsten powder production5.

-

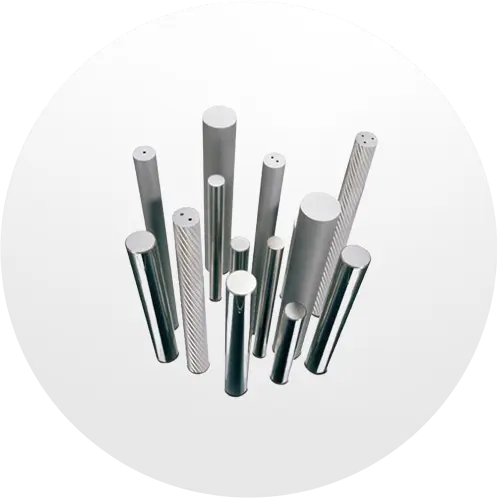

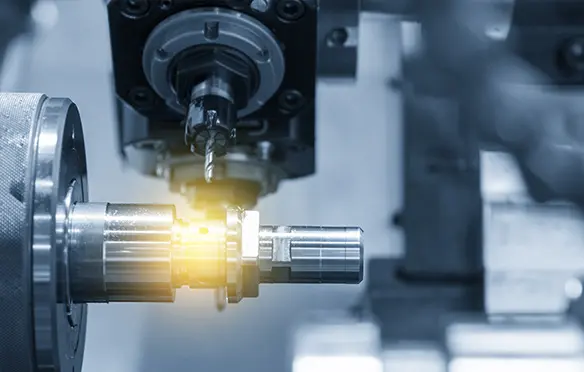

Midstream: Hard alloy inserts, rods, and CNC blades47.

-

Downstream: PCB micro-drills, Cutting Tools, and recycling systems17.

-

-

Circular Economy: Automated scrap recovery achieves >95% tungsten reclamation, directly addressing EU CBAM carbon-cost pressures17.

-

Rare Earth Synergy: Co-location with rare earth resources enables hybrid alloys for motors and electronics, enhancing value-chain depth28.

⚡ 3. Technology Capabilities

-

Material Breakthroughs: Local R&D has mastered thermal-barrier coatings and ultra-fine grain alloys, matching global leaders in hardness (≥2,200 HV) and bonding strength46.

-

Rapid Industrialization: Provincial "lab-to-market" systems accelerated 126+ patents to commercialization within 5 years, reducing client tooling costs by 30%47.

-

Standardization Influence: Increasing role in ISO-grade specifications for Carbide Tools, elevating global market credibility4.

🌐 4. Policy Support and Market Access

-

Logistics Efficiency: Dedicated rail corridors cut EU delivery times from 60 to 20 days, supporting just-in-time manufacturing1.

-

Industrial Targets: Provincial "1269 Action" and Ganzhou’s "7510 Plan" target $42B+ materials revenue by 2026, backed by RCEP tariff reductions saving exporters ~$500K/year12.

-

Quality Certification: "Golden Pagoda" branding signals premium-grade alloys to international buyers, enhancing export competitiveness4.

♻️ 5. Sustainable Production

-

Green Processing: Pioneered cement kiln co-processing of tungsten slag, achieving near-zero waste and EU-standard emissions16.

-

Carbon Efficiency: Recycling systems slash embedded emissions by 40%, preempting carbon border taxes17.

💎 Strategic Position: A Global Alloy Hub

Jiangxi’s triad of resource depth, technological agility, and policy coherence delivers unmatched cost-quality optimization. With 2,500+ tons/year of high-end alloy capacity launching by 2025, it transitions from supplier to systemic partner in global industrial chains157.

In materials geopolitics, Jiangxi offers supply chain resilience alongside advanced alloys. 🔋🛡️

Value Proposition for International Partners:

✅ Risk Mitigation: Vertical integration minimizes external dependencies.

✅ Technology Access: R&D velocity ensures next-generation alloy availability.

✅ ESG Compliance: Circular systems align with EU sustainability mandates.