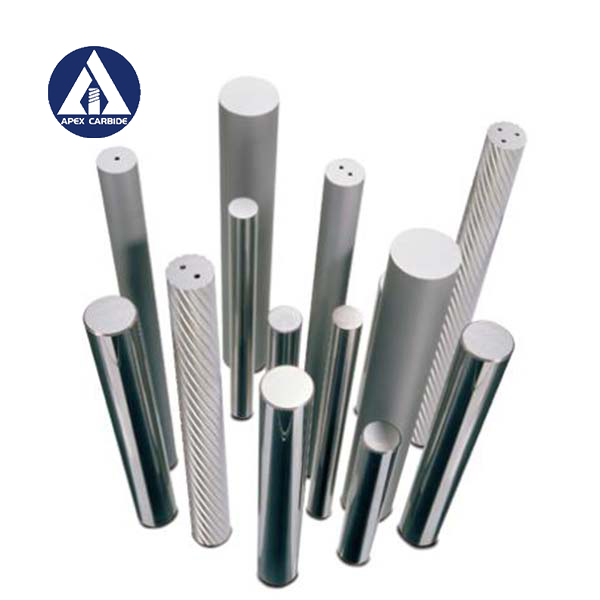

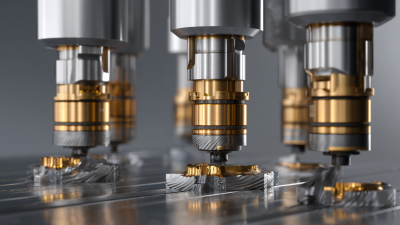

Tungsten Carbide Drawing Dies for Precision Engineering and Durable Performance

High-quality Tungsten Carbide Drawing Dies are crucial for precision in your manufacturing processes. With extensive experience at Jiangxi Apex Carbide Co., Ltd., I provide dies specifically designed to enhance durability and improve efficiency, resulting in lower production costs. Our advanced drawing dies cater to a wide range of industrial needs, ensuring optimal performance every time. As a B2B purchaser, you can rely on our Tungsten Carbide Drawing Dies for their exceptional hardness and wear resistance, making them a valuable investment for your operations.Methods To Choose Tungsten Carbide Drawing Dies Supplier Manufacturer

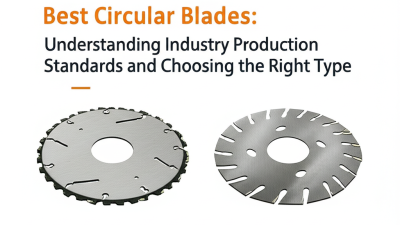

When selecting a tungsten carbide drawing dies supplier and manufacturer, several key factors must be considered to ensure you choose a reliable partner. One of the foremost aspects is the quality of the products offered. Companies like Jiangxi Apex Carbide Co., Ltd, with a specialization in high-quality Cemented Carbide products, provide a range of items beloved in the industry, including carbide rods, plates, blades, and circles. Their impressive annual output of 2000 tons speaks volumes about their capacity to meet large-scale demand, making them a formidable option for global buyers. Another crucial factor is the supplier's ability to maintain consistency and precision in their manufacturing processes. Seek suppliers who implement stringent quality control measures and have certifications that attest to their manufacturing standards. In addition, consider the supplier's experience in the industry; established companies with a solid track record are more likely to deliver products that meet the rigorous demands of various applications. Lastly, effective communication and customer support are vital indicators of a supplier's reliability. A responsive supplier will address inquiries promptly and provide technical assistance when needed, ultimately leading to a smoother collaboration. By considering these points and exploring supplier profiles, global buyers can make informed decisions when selecting their tungsten carbide drawing dies supplier.

Methods To Choose Tungsten Carbide Drawing Dies Supplier Manufacturer

| Criteria | Description | Importance Level | Evaluation Method |

|---|---|---|---|

| Material Quality | Assess the quality of tungsten carbide used. | High | Material certifications and sample testing. |

| Manufacturing Process | Understand the manufacturing techniques employed by the supplier. | Medium | Factory visits and process documentation review. |

| Customization Options | Capability to produce dies according to specific requirements. | High | Discussion with the supplier and previous case studies. |

| Lead Time | Delivery time from order to production. | Medium | Supplier's delivery schedule and feedback from previous clients. |

| Price Competitiveness | Evaluate pricing compared to industry standards. | Medium | Market research and quotes from multiple suppliers. |

| Customer Support | Quality and responsiveness of customer service. | High | Client reviews and response time analysis. |

| References and Testimonials | Feedback from other customers about their experiences. | High | Collect references and check online ratings. |

How To find Tungsten Carbide Drawing Dies Products Supplier

D

Daniel B. Lee

Absolutely delighted with my purchase. The product quality is outstanding and the service was timely and attentive.

09 May 2025

L

Lucas J. Taylor

Excellent craftsmanship! The customer support team was also very professional and knowledgeable.

02 June 2025

E

Elena R. Scott

A reliable product with a great support team! They genuinely care about their customers.

22 May 2025

A

Ava K. Morgan

This product is phenomenal! The service was equally commendable and professional.

15 May 2025

B

Benjamin E. Carter

Impressive product quality! The team provided excellent follow-up.

10 May 2025

T

Tobias K. Hayes

Purchased with confidence! Excellent quality and a service team that truly cares.

29 June 2025