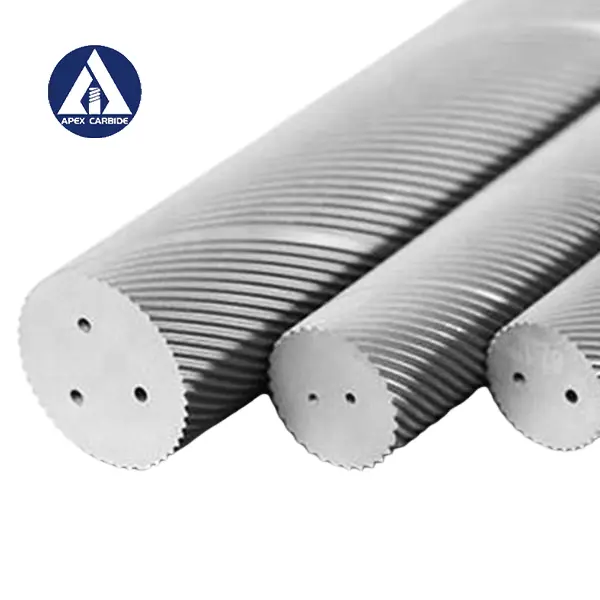

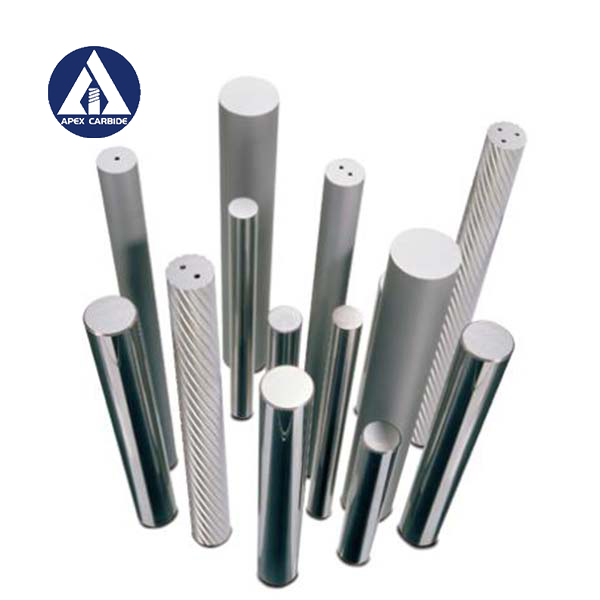

Tungsten Carbide Rods with Coolant Holes for Improved Machining Efficiency

Are you in need of high-quality tungsten carbide rods designed for optimal manufacturing efficiency? Our carbide rods with coolant holes significantly improve cooling during cutting operations, extending tool life and enhancing performance. With competitive pricing and a guarantee of superior strength and wear resistance, our products cater to diverse industrial requirements. At Jiangxi Apex Carbide Co., Ltd., we focus on exceeding your expectations with our engineering-grade solutions. Join a growing number of satisfied clients who have transformed their production capabilities with our reliable tungsten carbide materials. Elevate your processes with our exceptional offerings today.Why Choose Tungsten Carbide Rods With Coolant Hole Factory Products

When it comes to precision machining and manufacturing, tungsten carbide rods with coolant holes stand out as a superior choice. At Jiangxi Apex Carbide Co., Ltd, we specialize in high-quality cemented carbide products, including these essential rods that enhance machining efficiency. With an impressive annual output of 2000 tons of various carbide blanks, our factory is poised to meet the needs of global buyers with reliability and expertise. One of the significant advantages of our tungsten carbide rods with coolant holes is their ability to facilitate better cooling during the machining process. This innovative design allows for a continuous flow of coolant, reducing heat buildup and prolonging tool life. By choosing our factory products, you gain access to cutting-edge technology and exceptional performance, essential for maintaining high production standards and achieving optimal results in your operations. In addition to quality and performance, partnering with Jiangxi Apex Carbide Co., Ltd means you receive dedicated service and support from a team that understands the nuances of the industry. Our commitment to excellence and customer satisfaction ensures that we are not just suppliers but partners in your success. Choose our tungsten carbide rods with coolant holes for your manufacturing needs and experience the difference in quality, efficiency, and value.

Why Choose Tungsten Carbide Rods With Coolant Hole Factory Products

| Feature | Description | Advantages | Applications |

|---|---|---|---|

| Durability | High resistance to wear and tear, providing a longer service life. | Reduces replacement frequency, saving costs. | Heavy machining, metal cutting. |

| Heat Management | Coolant hole design allows for effective cooling during machining. | Improves tool performance and surface finish. | Precision drilling, milling operations. |

| Versatility | Compatible with a wide range of machines and operations. | Increases productivity across different applications. | Automotive, aerospace manufacturing. |

| Precision | Manufactured to tight tolerances for accuracy. | Enhances quality of finished products. | Electronics, medical devices. |

| Cost-Effectiveness | Higher upfront cost but lower overall expense. | Provides good return on investment. | High-volume production runs. |

Why Choose Tungsten Carbide Rods With Coolant Hole Factory Manufacturer

L

Lily N. Clark

Impressed with the level of craftsmanship! Their support staff are friendly and extremely efficient.

22 June 2025

C

Caleb H. Mitchell

Highly impressed with both the product quality and the level of service provided.

16 June 2025

N

Naomi J. Walker

An outstanding product and service team! They really made my experience smooth.

27 May 2025

M

Maria K. Bennett

Fabulous product quality! Timely and professional support made it even better.

22 June 2025

B

Benjamin E. Carter

Impressive product quality! The team provided excellent follow-up.

10 May 2025

M

Maya S. Kelly

High-quality and reliable! The support team was quick and helpful throughout my transaction.

13 May 2025