High-Performance Carbide Tools for Precision Engineering and Cutting Applications

At Jiangxi Apex Carbide Co., Ltd., we pride ourselves on offering high-performance Carbide Tools that set the standard for quality and reliability in your industry. Our product range is engineered for superior durability and precision, catering to diverse applications in manufacturing and construction. Committed to enhancing productivity, our tools feature exceptional wear resistance and cutting performance, resulting in reduced operational costs and improved efficiency. With a strong focus on quality assurance, every tool we provide is crafted to exceed expectations. Partnering with us means investing in innovation and dependable solutions that will elevate your operations.

Methods To Choose Carbide Tools Factory Supplier

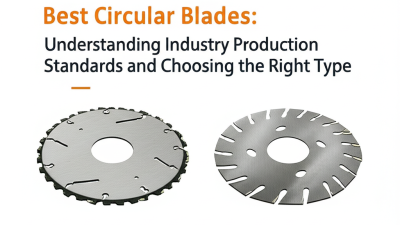

When it comes to sourcing carbide tools, selecting the right factory supplier can make a significant difference in your production quality and efficiency. Jiangxi Apex Carbide Co., Ltd is an established leader in the field, specializing in high-quality cemented carbide products such as carbide rods, plates, blades, and circles. With an impressive annual output of 2,000 tons of carbide blanks, the company demonstrates its capability to meet diverse market demands. When evaluating potential suppliers, consider their production capacity and quality assurance protocols. An experienced supplier like Jiangxi Apex not only guarantees a steady supply of high-performance carbide tools but also emphasizes stringent quality control measures to ensure that every product meets international standards. Furthermore, assess their technological advancements and the variety of products offered; Jiangxi Apex boasts a comprehensive range tailored to various applications, which can save you time and resources in your global procurement efforts. Ultimately, establishing a solid partnership with a reliable supplier such as Jiangxi Apex Carbide Co., Ltd can enhance your business operations. By focusing on quality, consistency, and versatility in product offerings, you can ensure your manufacturing processes are efficient and your end products are of superior quality, making your venture a success in today's competitive market.

Methods To Choose Carbide Tools Factory Supplier

| Selection Criteria | Description | Importance Level |

|---|---|---|

| Quality Control Processes | Assess the supplier's quality management systems and certifications. | High |

| Production Capacity | Evaluate the supplier's ability to meet your volume requirements. | High |

| Pricing | Compare pricing models and ensure they are competitive. | Medium |

| Lead Time | Understand the turnaround time for order fulfillment. | High |

| Customer Support | Evaluate the level of service provided before and after sale. | Medium |

| Location | Consider the geographical proximity for shipping efficiency. | Medium |

| Reputation and Reviews | Research feedback from other customers regarding their experiences. | High |

| Technological Advancements | Assess the technology used in manufacturing their tools. | Medium |

Why Choose Carbide Tools Manufacturer Supplier

J

James T. Anderson

I am immensely impressed with the quality of the product. It stands out for its durability and reliability, making my procurement decisions much easier.

04 July 2025

L

Leo N. Martinez

Highly satisfied with the quality and after-sales support. They really know how to treat their customers right!

17 June 2025

M

Matthew D. Gutierrez

Quality and service were both exceptional. I felt valued as a customer throughout the entire process.

03 June 2025

I

Isabella P. Robinson

A fantastic product with exceptional finish. The support team was professional and truly dedicated.

16 June 2025

L

Layla C. Reyes

Superb quality product! Remarkably efficient assistance from the support team.

16 June 2025

S

Sophie M. Rogers

Stellar product! The professionalism shown by the support staff was greatly appreciated.

16 June 2025