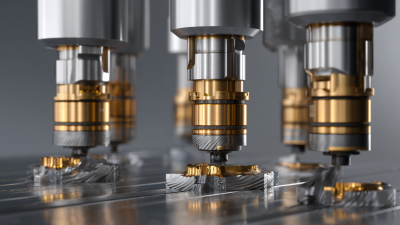

Enhance Precision Cutting of Tool Steel with Quality End Mills

For high-performance machining of tough materials, our end mills for tool steel are engineered to deliver exceptional precision and durability. Designed specifically for tool steel applications, these end mills ensure sharpness and smooth cutting, contributing to an extended tool life. With a variety of sizes and configurations available, they support optimized production schedules, catering to the timely needs of your B2B purchases. Rely on our products for consistent quality and dependable performance, backed by fast shipping and responsive customer support. Enhance your machining operations with Jiangxi Apex Carbide Co., Ltd.’s reliable solutions.

Methods To Choose End Mills For Tool Steel Products Factory

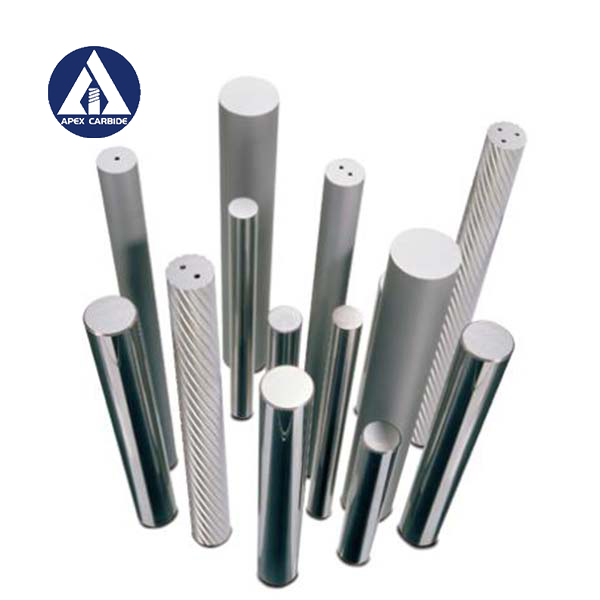

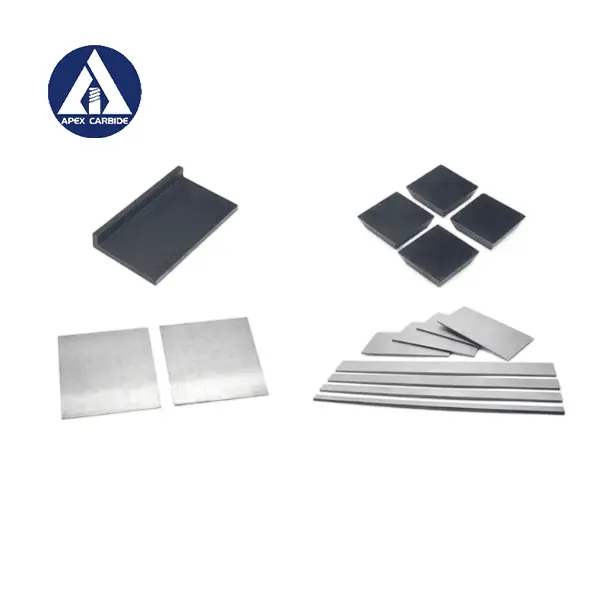

When selecting end mills for tool steel products, especially in a factory setting like Jiangxi Apex Carbide Co., Ltd, it’s crucial to consider several key factors to enhance machining efficiency and product quality. Firstly, understanding the type of tool steel being processed is essential as different grades vary in hardness and toughness. For instance, high-speed steels are often used in applications requiring durability, while other variants may necessitate specific carbide milling tools designed for enhanced performance. Secondly, the geometry of the end mill plays a significant role in performance. Considerations such as the number of flutes, helix angle, and cutting edge design can dramatically affect chip removal rates and surface finish. Manufacturers should opt for end mills that optimize these aspects depending on the machining operation, whether it be roughing or finishing. Jiangxi Apex Carbide Co., Ltd, with its extensive range of high-quality Cemented Carbide products, can provide insights on choosing the right end mill tailored to your specific needs. Lastly, selecting the right coating for the end mill can improve tool life and performance. Coatings such as TiAlN or TiN can significantly enhance wear resistance and reduce friction, making them suitable for machining tough tool steels. It is advisable to consult with carbide manufacturers like Jiangxi Apex Carbide Co., Ltd to get recommendations on the optimal products based on the specifics of your operations. By making informed decisions on end mill selection, global buyers can ensure they achieve efficiency and cost-effectiveness in their production processes.

Methods To Choose End Mills For Tool Steel Products Factory

| Criteria | Description | Recommended Type |

|---|---|---|

| Material Hardness | Determines the necessary tool material and coating for effective machining. | Solid Carbide End Mills |

| Tool Geometry | Includes flute shape, helix angle, and number of flutes, affecting chip removal. | 5-Flute Spiral End Mills |

| Coating | Enhances wear resistance and reduces friction during machining. | TiN or TiAlN Coated End Mills |

| Cutting Speed | Optimal speeds reduce tool wear and improve finish quality. | High-Feed Face Mills |

| Lubrication | Aids in heat dissipation and prolongs tool life. | Flood Coolant Systems |

| Application | Specifies whether the tool is for roughing, finishing, or high-speed machining. | Finishing End Mills for Tool Steel |

Methods To Choose End Mills For Tool Steel Manufacturer Factory

L

Liam B. Davis

Very pleased with the product quality! The service staff were incredibly helpful and professional.

27 June 2025

A

Aiden T. Carter

Fantastic product quality; equally impressive was the quality of service provided by the team.

07 June 2025

J

James P. Robinson

Top-notch product quality complemented by a highly professional support team!

09 June 2025

M

Matthew Y. Nguyen

A fantastic experience from start to finish! Quality products backed by a dedicated service team.

16 June 2025

B

Benjamin E. Carter

Impressive product quality! The team provided excellent follow-up.

10 May 2025

J

Jaxon Y. Carter

This product has exceeded my expectations over and over! The service was equally attentive.

28 June 2025