Single Flute End Mill: Precision Cutting Tool for Efficient and Reliable Machining

For precision and reliability in machining, the Single Flute End Mill from Jiangxi Apex Carbide Co., Ltd. stands out as an essential tool. Ideal for high-speed machining applications, these end mills excel when working with aluminum and plastics. Their innovative design minimizes chip buildup, facilitating smoother cuts and extending tool life. The efficient chip removal capability is particularly advantageous during detailed milling tasks. Coupled with exceptional durability and sharp cutting edges, this tool enhances machining efficiency, saving both time and materials. Additionally, the competitive pricing makes it a valuable choice for businesses aiming to improve production capabilities while staying within budget. For those focused on elevating their machining processes, these Single Flute End Mills are highly recommended and have significantly improved my operations.

How To find Single Flute End Mill Supplier Products

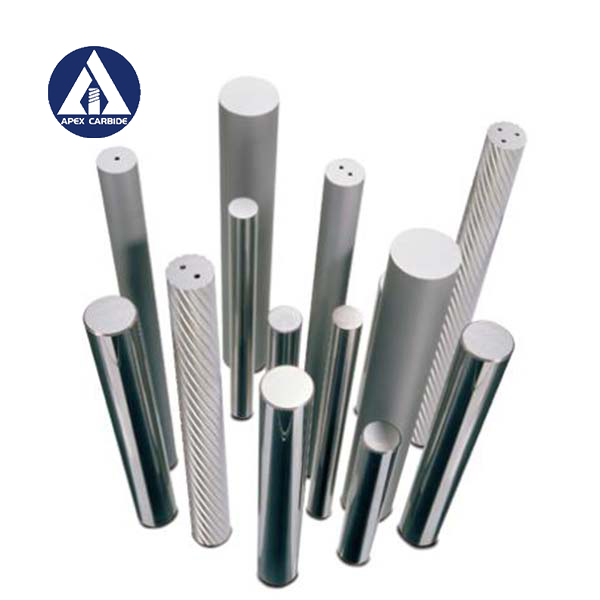

When sourcing a single flute end mill, identifying reliable suppliers is crucial for ensuring the quality and performance of your tooling. One of the key players in this field is Jiangxi Apex Carbide Co., Ltd. With a strong focus on high-quality Cemented Carbide products, the company produces an array of essential tools including carbide rods, plates, blades, and circular saws. Their commitment to excellence and innovation has led to an impressive annual output of 2000 tons, signifying their capacity to meet global demand. To find the right single flute end mill supplier, start by researching companies that specialize in cemented carbide products. Look for manufacturers with a proven track record, like Jiangxi Apex Carbide, which not only caters to various industrial needs but also emphasizes quality control throughout their production process. Utilizing platforms such as industry trade shows, online marketplaces, and networking within industry groups can also help you uncover reputable suppliers who are noted for their reliability and performance. Furthermore, consider requesting samples from potential suppliers to evaluate the performance of their single flute end mills in your specific applications. Engaging in direct communication with the supplier about their manufacturing processes, quality assurance measures, and after-sales support will also provide deeper insights into their capabilities. By doing thorough research and leveraging the expertise of recognized manufacturers such as Jiangxi Apex Carbide Co., Ltd, you can make informed decisions that ensure you receive high-quality tools that meet your production needs.

How To Find Single Flute End Mill Supplier Products

| Product ID | Diameter (mm) | Length (mm) | Material Type | Coating | Price ($) | Supplier Contact |

|---|---|---|---|---|---|---|

| EM-001 | 6 | 50 | High-Speed Steel | TiN | 15.99 | contact@supplier1.com |

| EM-002 | 8 | 60 | Carbide | TiAlN | 29.49 | info@supplier2.com |

| EM-003 | 10 | 70 | Cobalt | ZrN | 35.00 | sales@supplier3.com |

| EM-004 | 12 | 80 | Carbide | AlTiN | 48.75 | support@supplier4.com |

How To find Single Flute End Mill Products Supplier

S

Samantha L. Chen

The after-sales service was exceptional. The representative was knowledgeable and addressed all my concerns with professionalism.

18 June 2025

J

Jennifer K. Rivera

This purchase was worth every penny! The professionalism displayed by the support team was impressive.

25 May 2025

S

Samantha D. Wright

Such an excellent experience! The product is top-notch, and the customer service is truly outstanding.

27 June 2025

N

Naomi J. Walker

An outstanding product and service team! They really made my experience smooth.

27 May 2025

B

Benjamin E. Carter

Impressive product quality! The team provided excellent follow-up.

10 May 2025

L

Liam V. Martinez

Excellent! The product is superb, and the support from the team made everything easier.

24 June 2025