Tungsten Carbide Cutting Discs: Superior Precision & Unmatched Durability for Cutting

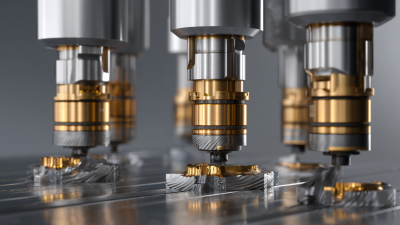

When it comes to reliable and long-lasting cutting solutions, our Tungsten Carbide Cutting Discs stand out. Engineered for precision and durability, these high-performance discs excel in cutting through a range of materials, including metal and concrete. You can rely on their exceptional hardness and wear resistance to keep your projects on track. At Jiangxi Apex Carbide Co., Ltd., we prioritize quality, having developed our cutting discs through rigorous research and testing. Tailored to meet industrial demands, we offer various sizes and specifications to address your unique needs. Opt for our cutting discs to enhance your productivity and efficiency in all operations!Why Choose Tungsten Carbide Cutting Discs Products Manufacturer

When it comes to high-performance cutting tools, tungsten carbide cutting discs stand out as a reliable choice for various industries. At Jiangxi Apex Carbide Co., Ltd, we specialize in the manufacturing of premium cemented carbide products, including tungsten carbide rods, plates, blades, and circular discs. With an impressive annual output capacity of 2000 tons, our commitment to quality and innovation makes us a trusted partner for global buyers seeking durable and efficient cutting solutions. Choosing Jiangxi Apex Carbide means opting for products that undergo rigorous quality control processes to ensure exceptional performance and longevity. Our cutting discs are designed to withstand the toughest conditions, providing superior cutting speed and extended service life. We pride ourselves on using high-grade raw materials, combined with advanced manufacturing techniques, ensuring that our products meet and exceed international standards. Our customer-centric approach allows us to provide tailored solutions to meet the unique needs of each client, enhancing their productivity and operational efficiency. Moreover, partnering with us translates to reliable supply chains and responsive service. We understand the demands of global procurement and are committed to delivering products on time, every time. With Jiangxi Apex Carbide, you can trust that you're selecting a manufacturer dedicated to excellence, innovation, and customer satisfaction, making your investment in tungsten carbide cutting discs a decision you won't regret.

Why Choose Tungsten Carbide Cutting Discs Products Manufacturer

| Feature | Description | Benefit |

|---|---|---|

| High Durability | Tungsten carbide is known for its toughness and resistance to wear. | Longer tool life, reducing replacement and maintenance costs. |

| Precision Cutting | Manufactured to exact specifications for optimal performance. | Enhanced accuracy in cuts, leading to better quality of work. |

| Versatility | Suitable for a wide range of materials including metals and composites. | Flexibility in applications, catering to different industry needs. |

| Cost-Effectiveness | Reduced frequency of purchases due to high durability. | Lower overall costs for businesses and individual users. |

| Safety Features | Designed with safety in mind to minimize risk during use. | Peace of mind for users, promoting a safer working environment. |

Why Choose Tungsten Carbide Cutting Discs Manufacturer Products

M

Michael R. Johnson

The product I received is of excellent quality, and the thoroughness of the installation team was commendable.

01 July 2025

D

David J. Perez

Quality and service that you can rely on! The follow-up by the support team was impressive.

06 July 2025

N

Natalie H. Adams

The level of expertise from the staff was apparent and made all the difference in my purchasing experience.

22 June 2025

S

Samantha D. Wright

Such an excellent experience! The product is top-notch, and the customer service is truly outstanding.

27 June 2025

L

Liam V. Martinez

Excellent! The product is superb, and the support from the team made everything easier.

24 June 2025

M

Maya S. Kelly

High-quality and reliable! The support team was quick and helpful throughout my transaction.

13 May 2025