- Solid Carbide Rods

- Carbide Rods with coolant holes

- Carbide Rods with Two Helix Holes

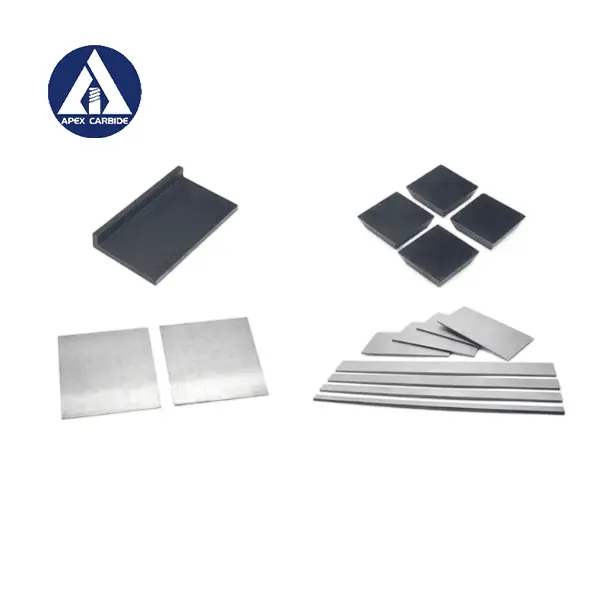

- Tungsten Carbide Flats

- Solid Carbide Discs

- Tungsten Carbide anti-vibration cylindrical shafts

- Non-standard Customized Carbide Blanks

- Solid Carbide Circular Saw Blade

- Solid Carbide Woodworking Blade

- Solide Carbide End Mills

- Solid Carbide Drills

- Carbide Rotary Burrs

- Customized Carbide Tools

0102030405

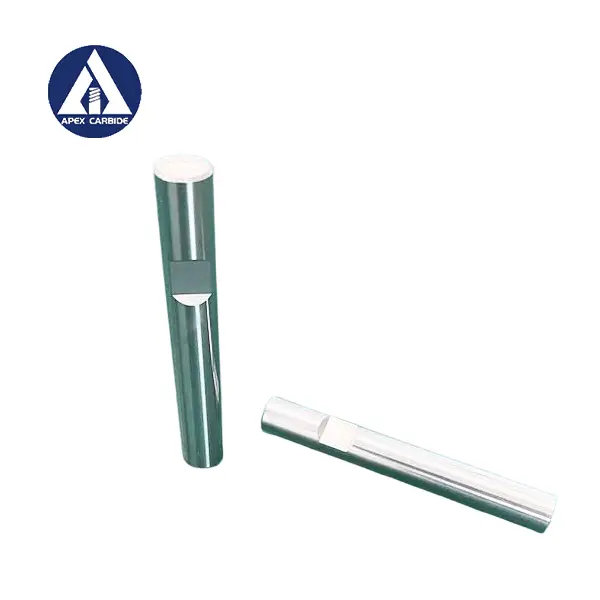

Tungsten solid carbide rods with customized weldon and h5 ground and chamfered

The introduction of carbide rods

1.The tungsten solid carbide rods is press molded by molding or extrusion.

2.The tungsten solid carbide rods is sintered by a low-pressure sintering integrated furnace, thus the overall performance is high.

3.The rough tungsten-cobalt carbide round bar, or the outer diameter of the round bar can be refined and polished according to any tolerance. The common tolerances are h5,h6, -0.005, etc., and the carbide rods end chamfer can also be processed.

4.Carbide rods is suitable for the processing of general steel, cast iron, stainless steel, heat resistant steel, nickel base and titanium alloy. Recommended for general purpose carbide tool materials such as twist drills, end mills, taps, and gun drills.

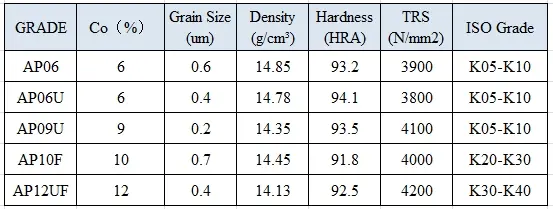

Introduction of our grades

Our Types of carbide Rods

1.Unground Long rods

| The TOL. of Unground Long rods | ||

| Size(DxL,mm) | Tolerance | |

| D(mm) | L(mm) | |

| D[1-3)x310/330 | 0.30~0.55 | 0.00~+4.00 |

| D[3-12)x310/330 | 0.30~0.60 | 0.00~+4.00 |

| D[12-20)x310/330 | 0.30~0.65 | 0.00~+4.00 |

| D[20-40]x310/330 | 0.30~0.70 | 0.00~+4.00 |

2.Unground cut-to-length rods

| The TOL. of unground cut-to-length rods | ||

| D/L(mm) | The TOL.of D&L in mm | |

| L<=70 | 70<L<=150 | |

| D<5 | D(0.20~0.30), L(0.20~1.5) | D(0.25~0.35), L(0.20~1.5) |

| 5<=D<40 | D(0.25~0.35), L(0.20~1.5) | D(0.30~0.40), L(0.20~1.5) |

3.Ground long rods

The tolerance of the long rods is h5/h6 or at customer’s requirement in Dia. ,and 0.00~+5.00mm in Length as normal.

4.Ground cut-to-length rods

The tolerance of the ground cut-to-length rods is h5/h6 or at customer’s requirement in Dia. ,and 0.00~+2.00mm in Length as normal.

5.PCB Rods

Production Process

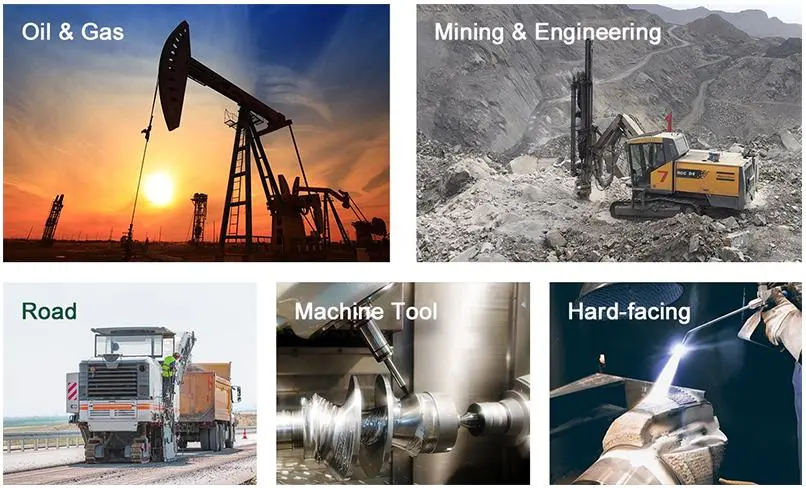

Industrial Solution

Why Choose APEX Carbide

Around 20 years production and management experience,Advanced production technology, High-precision machines, Strict QC management system, Special-designed packing boxes and tubes, Various shipping methods

2.Inspection and testing process

3.Advanced CNC Equipment

1.Tungsten carbide blanks production

Good quality carbide products rely on 100% virgin raw materials and advanced wet-milling,pressing machines and sintering furnaces. We put emphasize on every production process of our carbide blanks. To keep good quality of carbide blanks is the base of furtherly machined high precision finished carbide parts.

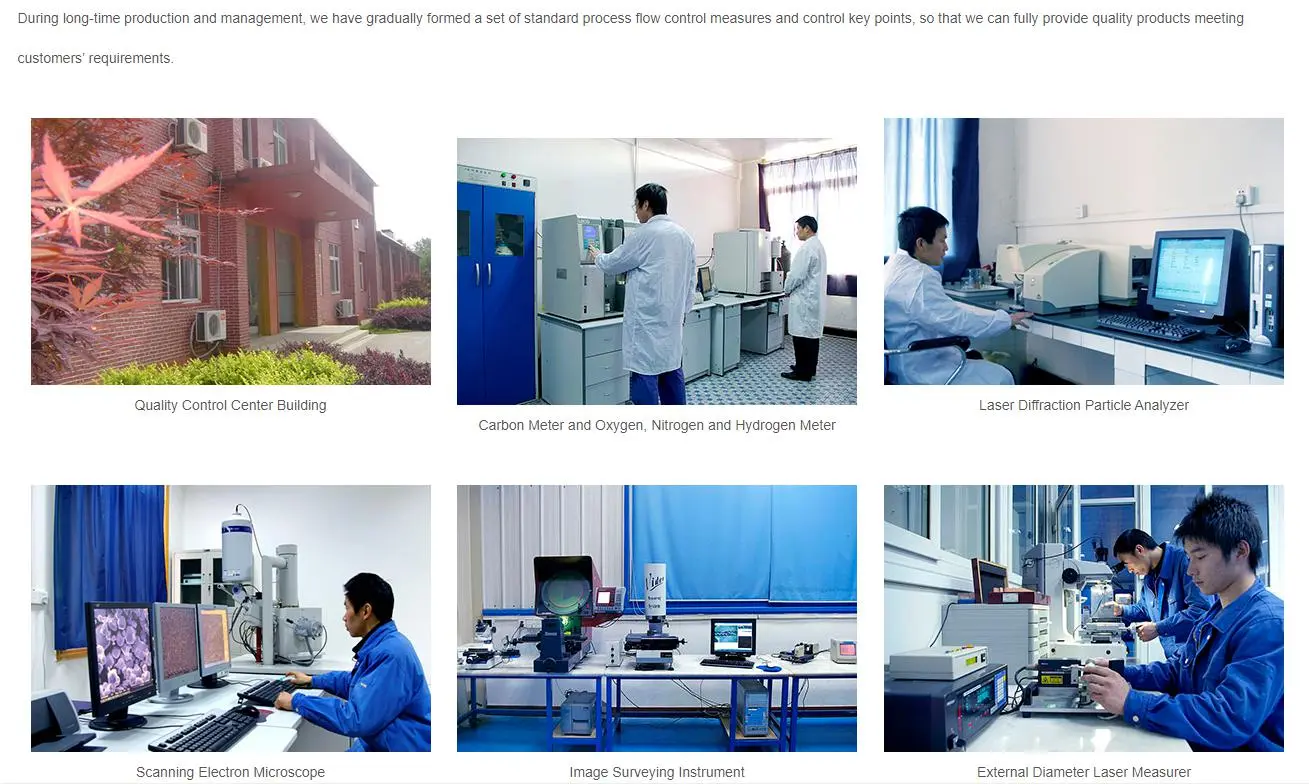

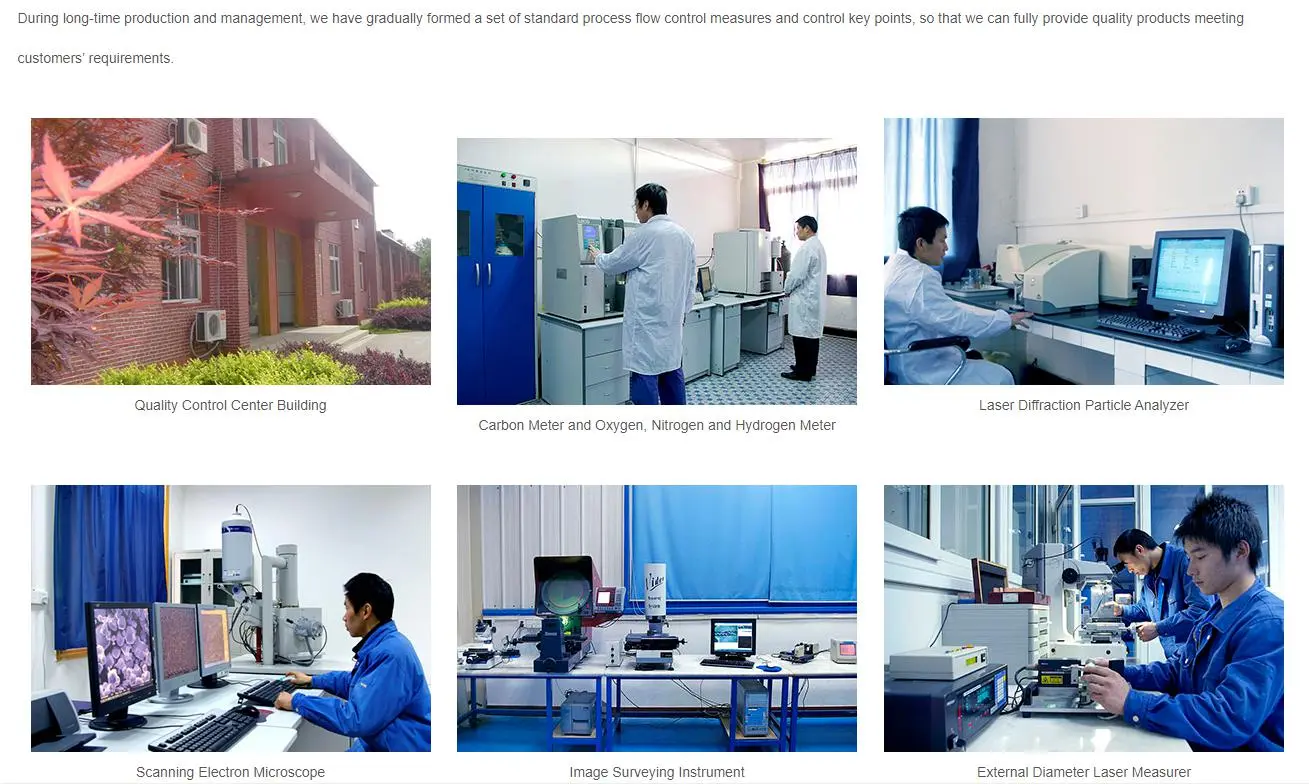

2.Inspection and testing process

In order to ensure the quality of all our tungsten carbide finished products, a very strict QC management system we called “Quality Control Center” has been introduced. With our advanced inspection equipment and our professional inspectors, we are able to do raw materials inspection, on-site inspection and after finishing inspection to ensure 100% good quality of your carbide products.

3.Advanced CNC Equipment

We own a series of high-precision grind machines, including flat grinding machines, OD and ID machines, Centerless grinding machines and customized grinders. Also we have CNC machines, EDM, Wire-cutting machines and drilling machines etc. With our skilled workers, we can control very high precision of each carbide part.

4.Packaging and Shipping

Special-designed packing boxes and tubes will be used properly for the standard and customized carbide products to ensure the safety of the goods during the transportation process.A wide range of shipping ways can be available for your shipments, for example we can ship goods by Sea, by air and by Express companies like DHL/FedEx/UPS/TNT etc.

- Carbide Blank Rods

- Carbide Grinding Rod

- Carbide Rod Blank

- Carbide Rods

- Carbide Solid Rod

- Cemented Carbide Rod

- Cemented Carbide Rods

- China Carbide Solid Rod

- China Cemented Carbide Rod

- H6 Polished Carbide Rods

- K10 Tungsten Carbide Rod

- Nanchang Tungsten Carbide

- Polished Rods

- Polished Tungsten Carbide Rod

- Rod For End Mills

- Round Carbide Rods

- Solid Carbide

- Tungsten Alloy Rods

- Tungsten Carbide Rod

- Tungsten Solid Carbide Rods

- Tungsten Solid Carbide Round Bars